Electric lifting platform control method capable of realizing rollback when meeting resistance

A lifting platform and control method technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of personal injury, inaccurate judgment, damage to the structure of the obstacle platform itself, and achieve high judgment accuracy and low false trigger probability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following specific embodiments.

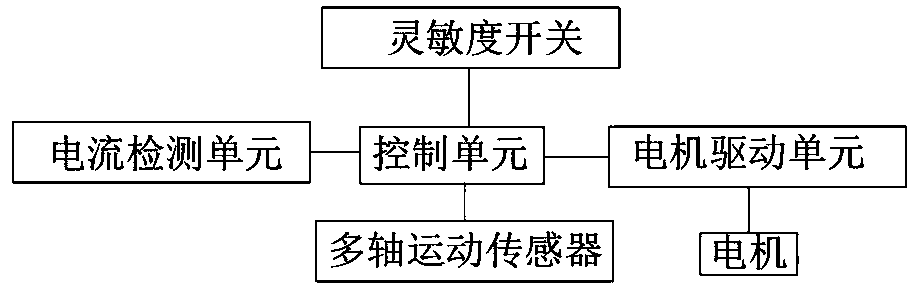

[0019] A control system for an electric lifting platform that realizes retreat in case of resistance. The electric lifting platform in this application is an electric lifting table, such as figure 1 As shown, it includes a control unit, a motor drive unit, a multi-axis motion sensor, a current detection unit, and a sensitivity switch, and the motor drive unit, the multi-axis motion sensor, and the current detection unit are all electrically connected to the control unit,

[0020] The multi-axis motion sensor is used to collect changes in the motion state of the desktop on different axes, that is, to detect the acceleration and angular velocity of the lifting platform. In the specific embodiment of the application, a six-axis motion sensor is used, mainly including a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com