Speed regulation control system of wiper blade

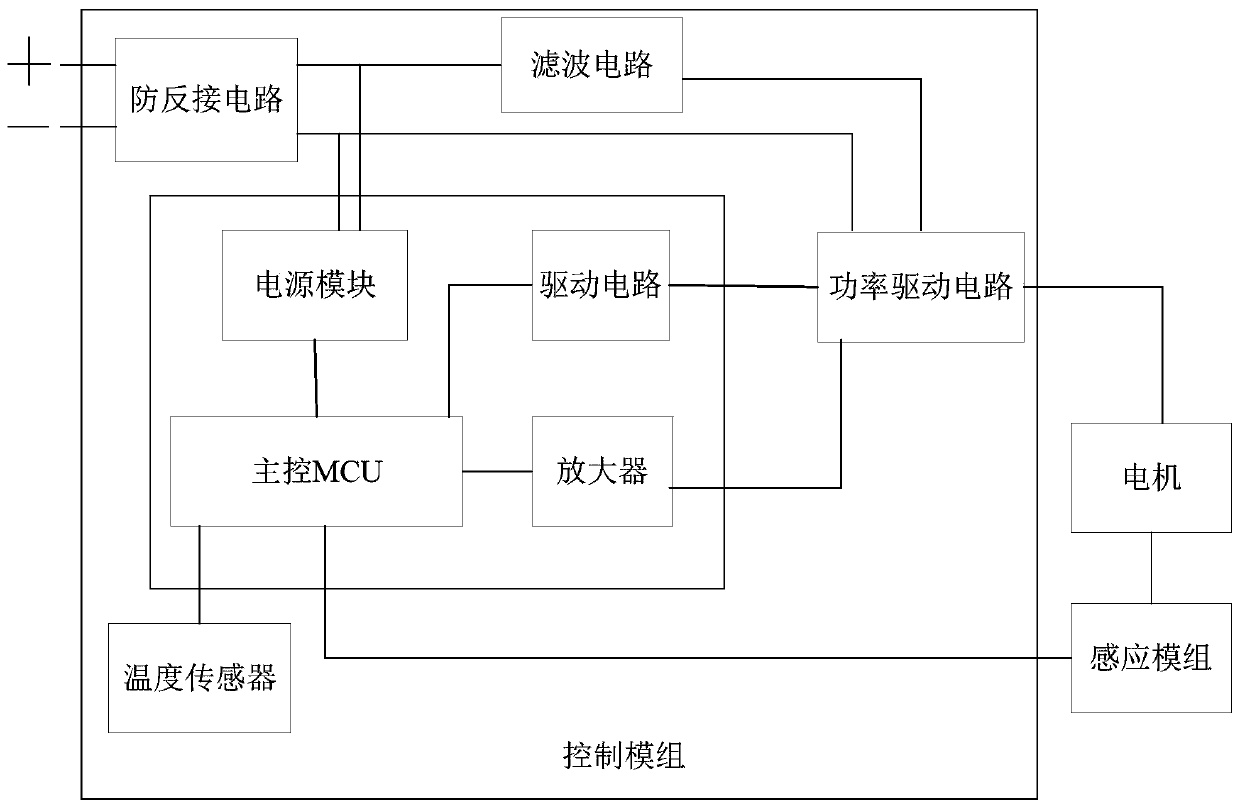

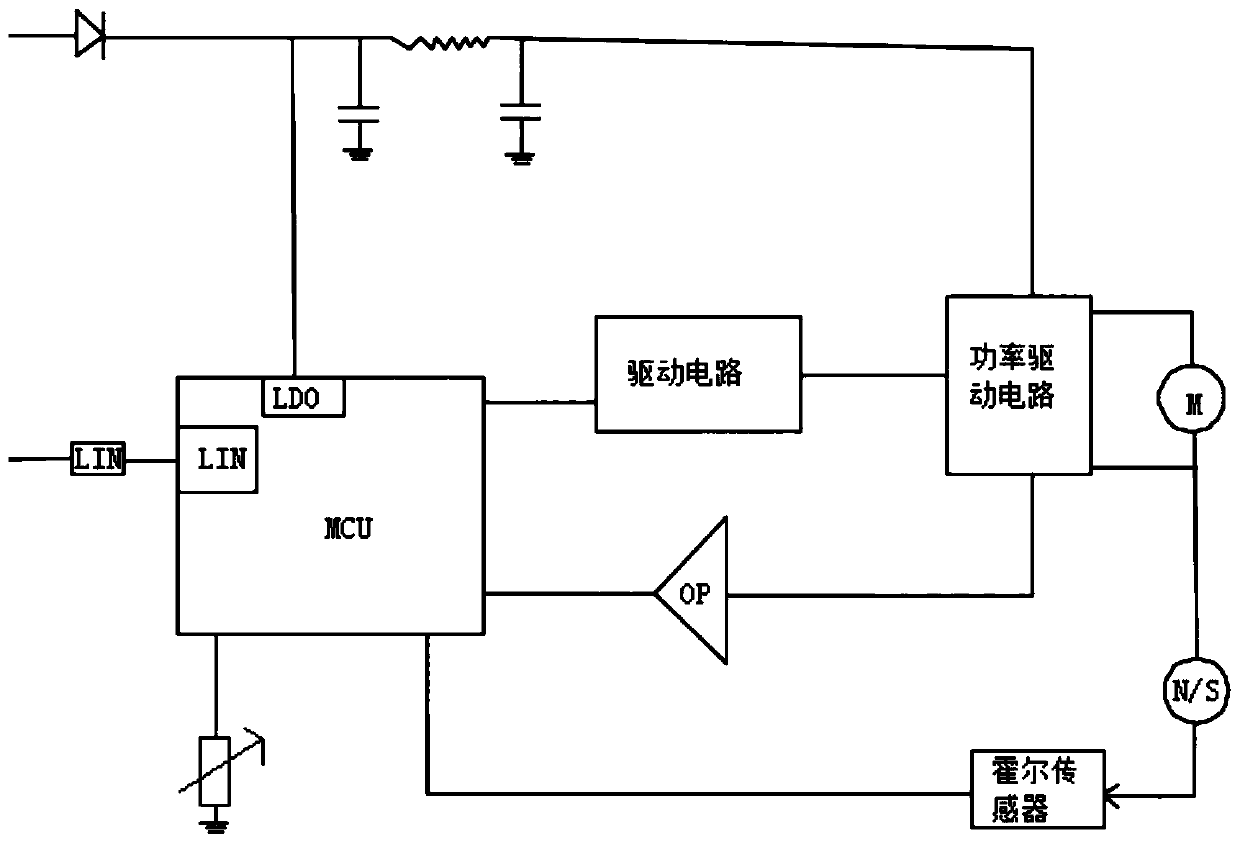

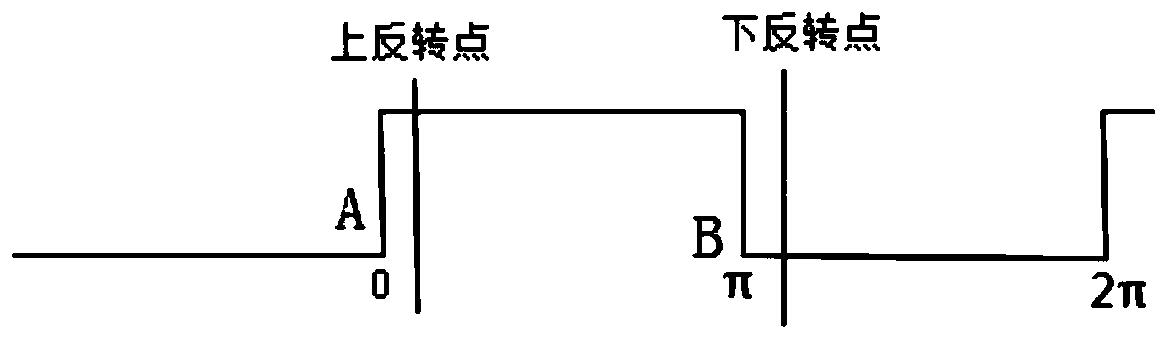

A control system and speed regulation technology, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve problems such as difficult adjustment of wiper reverse speed, reduce elastic deformation, increase wiper speed, reduce reverse turn noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0050] This example first provides an exemplary existing application scenario. The wiper used on the car is driven by a motor combined with a connecting rod structure. One of the driving methods is that the one-way movement of the motor is converted into the wiper through the connecting rod structure. Reciprocating motion on the glass surface, but the external power supply voltage of the motor is fixed (that is, the actual voltage provided to the motor is fixed), resulting in a fixed speed of the motor, and the motor can only run at a uniform speed in one direction, and cannot realize the scheduling of the wiper.

[0051]Based on the above application scenarios, in the embodiment of the present invention, a wiper speed regulation control system is provided. The design idea of the method is: convert the one-way motion of the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com