PVC pipeline cutting device

A technology for cutting devices and pipes, used in metal processing and other directions, can solve the problems of inconsistent pipe diameters, melting of saw blades and plastics, affecting the popularization and application of pipes, etc., and achieves the effect of smooth fracture section, ensuring integrity and sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

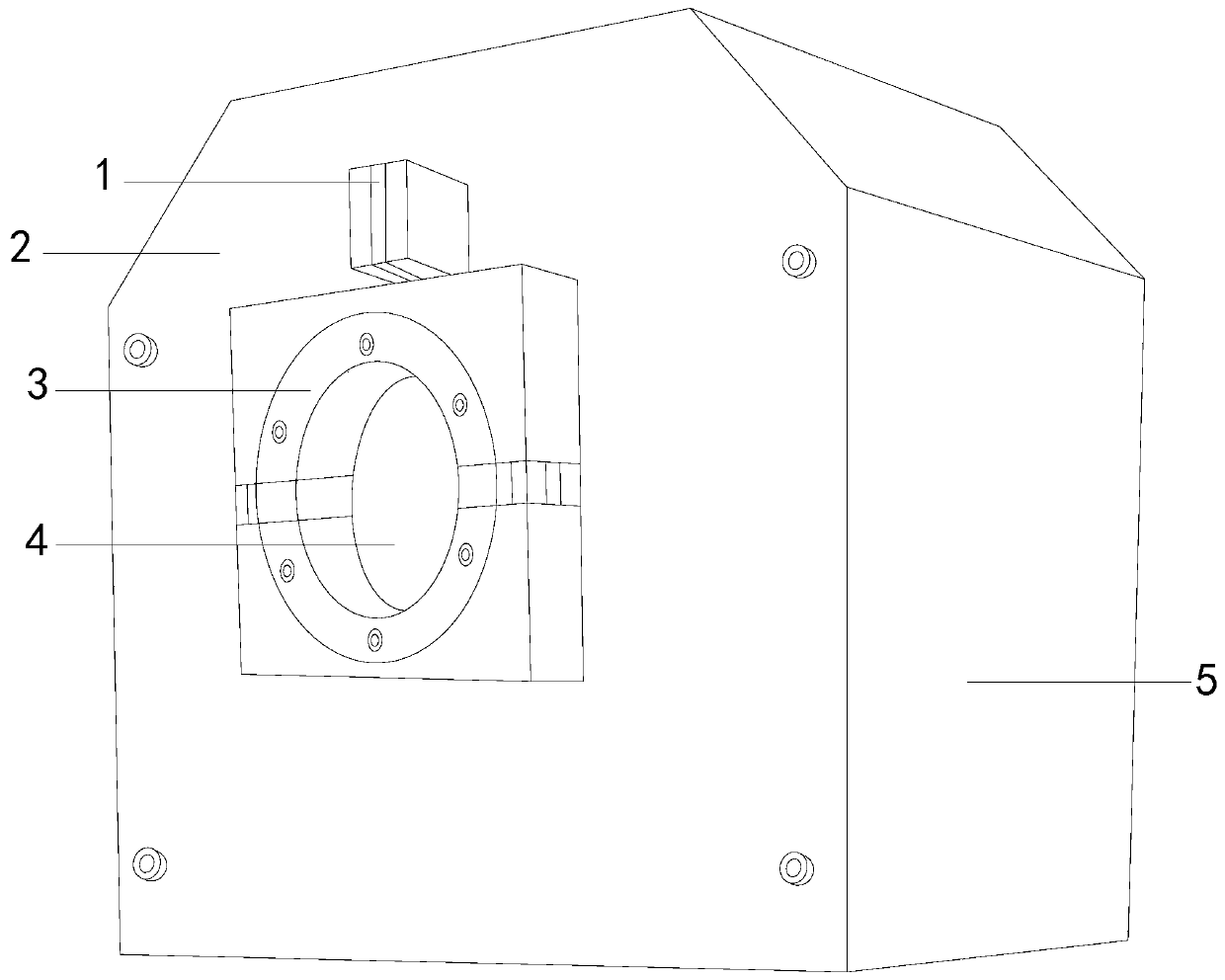

[0020] see figure 1 , the present invention provides a PVC pipe cutting device, its structure includes: a controller 1, a transmission mechanism 2, a cutting mechanism 3, a cutting ring 4, a base 5, the controller 1 is connected to the transmission mechanism 2, and the transmission mechanism 2 and The cutting mechanism 3 is connected, and the cutting mechanism 3 is provided with a cutting ring 4. The cutting ring 4 is set on the front surface of the base 5. The controller 1 sends an electronic pulse signal to transmit it to the transmission mechanism 2 and the cutting mechanism 3, and commands the transmission mechanism 2 and the cutting mechanism 3 make different actions according to the instructions of the controller to complete the cutting of the pipe.

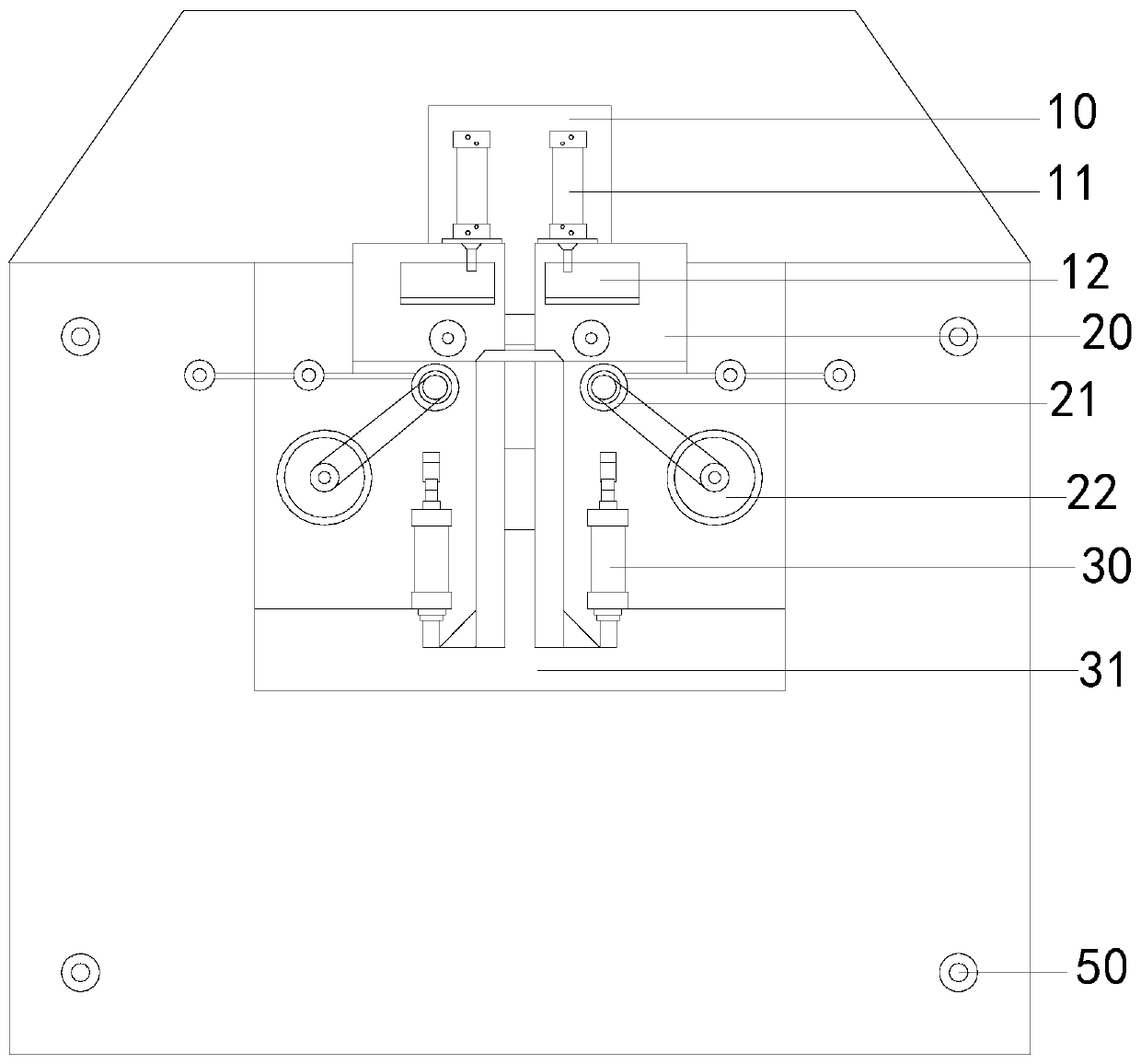

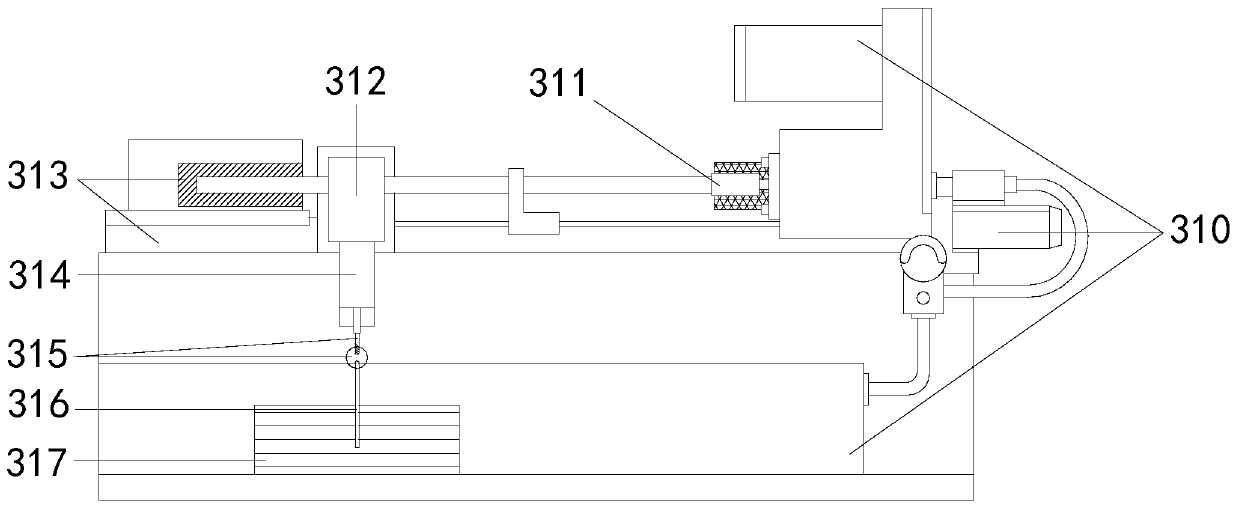

[0021] see figure 2 , the present invention provides a PVC pipe cutting device, its structure includes: the controller 1 is composed of a chip board 10, a spring rod 11, and a hydraulic pad 12, the chip board 10 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com