Automation equipment and method for pouring microbial agent in continuous lifting mode to cure tailings

A technology of microbial agent and automation equipment, which is applied to drilling equipment and methods, drilling equipment, earthwork drilling and mining, etc. It can solve problems such as unsatisfactory treatment effects, soil ecological environment damage, and secondary pollution, so as to avoid pollution The effect of transferring, saving microbial agents, and reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

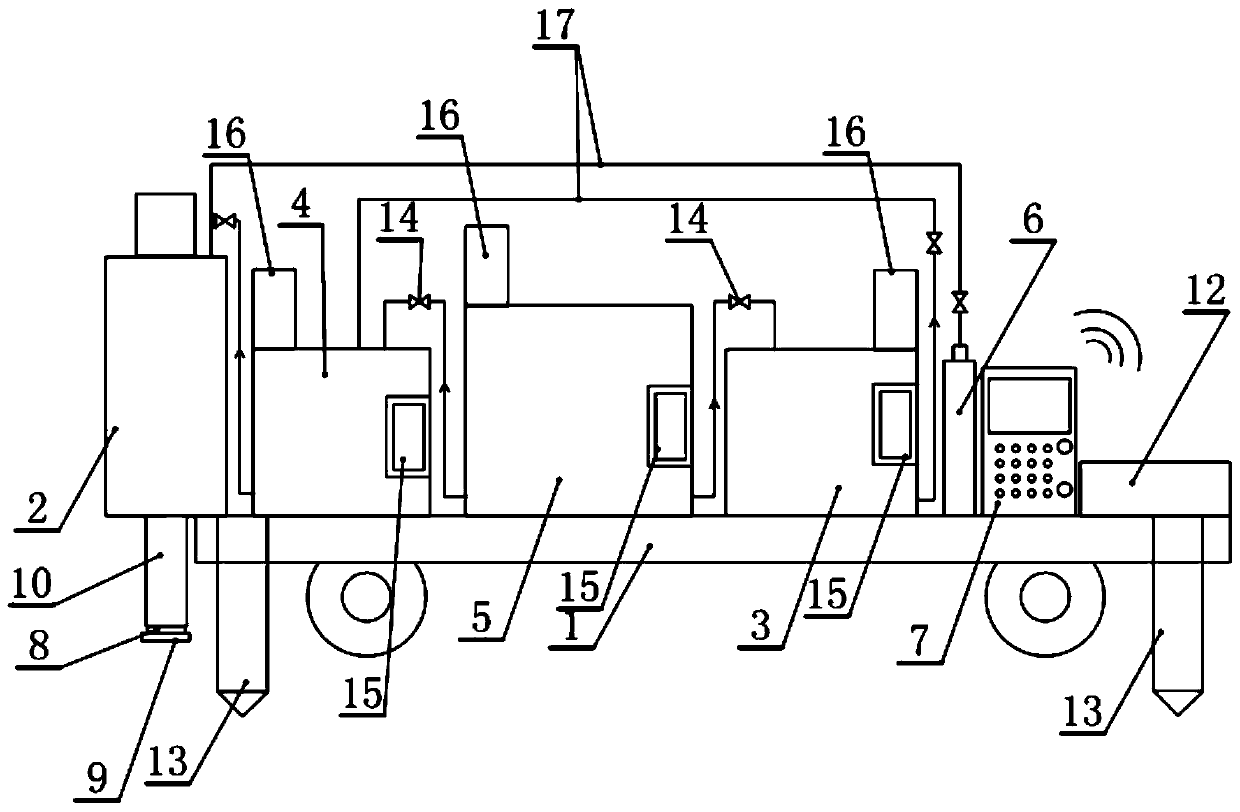

[0027] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

[0028] like figure 1 As shown, this kind of equipment for continuously lifting and injecting microbial agents to solidify tailings includes car body 1, drilling rig 2, microbial agent mixing system, high-pressure air pump and central control system, drilling rig, microbial agent mixing system, and high-pressure air pump 6 And central control system 7 are all installed on the car body. The air pressure of the high-pressure air pump and the mixing ratio of the microbial agent and water in the microbial agent mixing system are all controlled by the central control system.

[0029] Drill bit 9 is installed at the bottom of drill rod 8 of drilling rig, and drill bit is an alloy drill bit, and its drilling diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com