Breaking anti-blockage uniform application fertilizer apparatus with multi-stage breaking function

A technology of fertilizer discharger and function, which is applied in the direction of fertilization device, fertilizer distributor, grain processing, etc., and can solve the problems of clogging fertilizer discharger, poor crushing effect, and agglomeration of granular fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

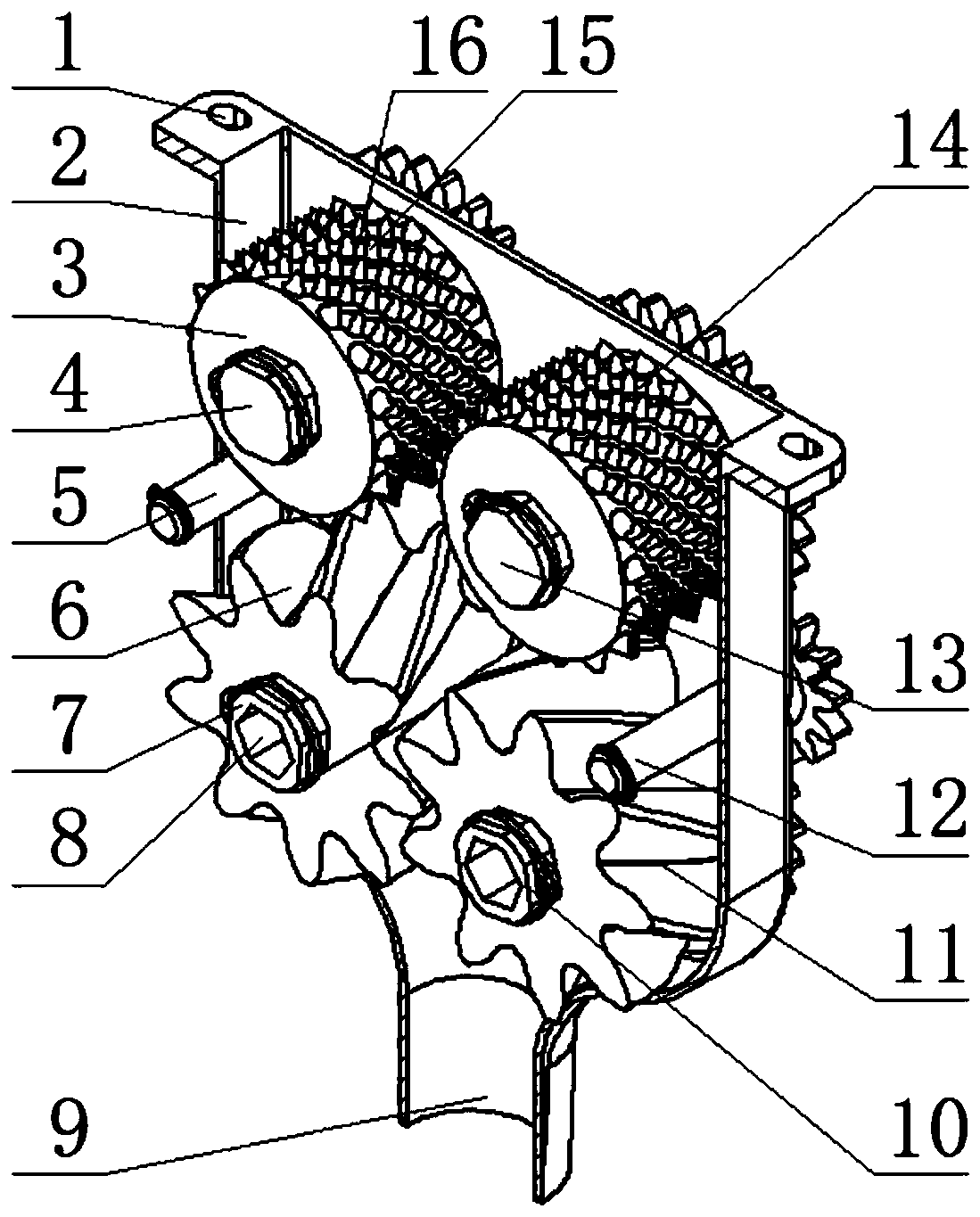

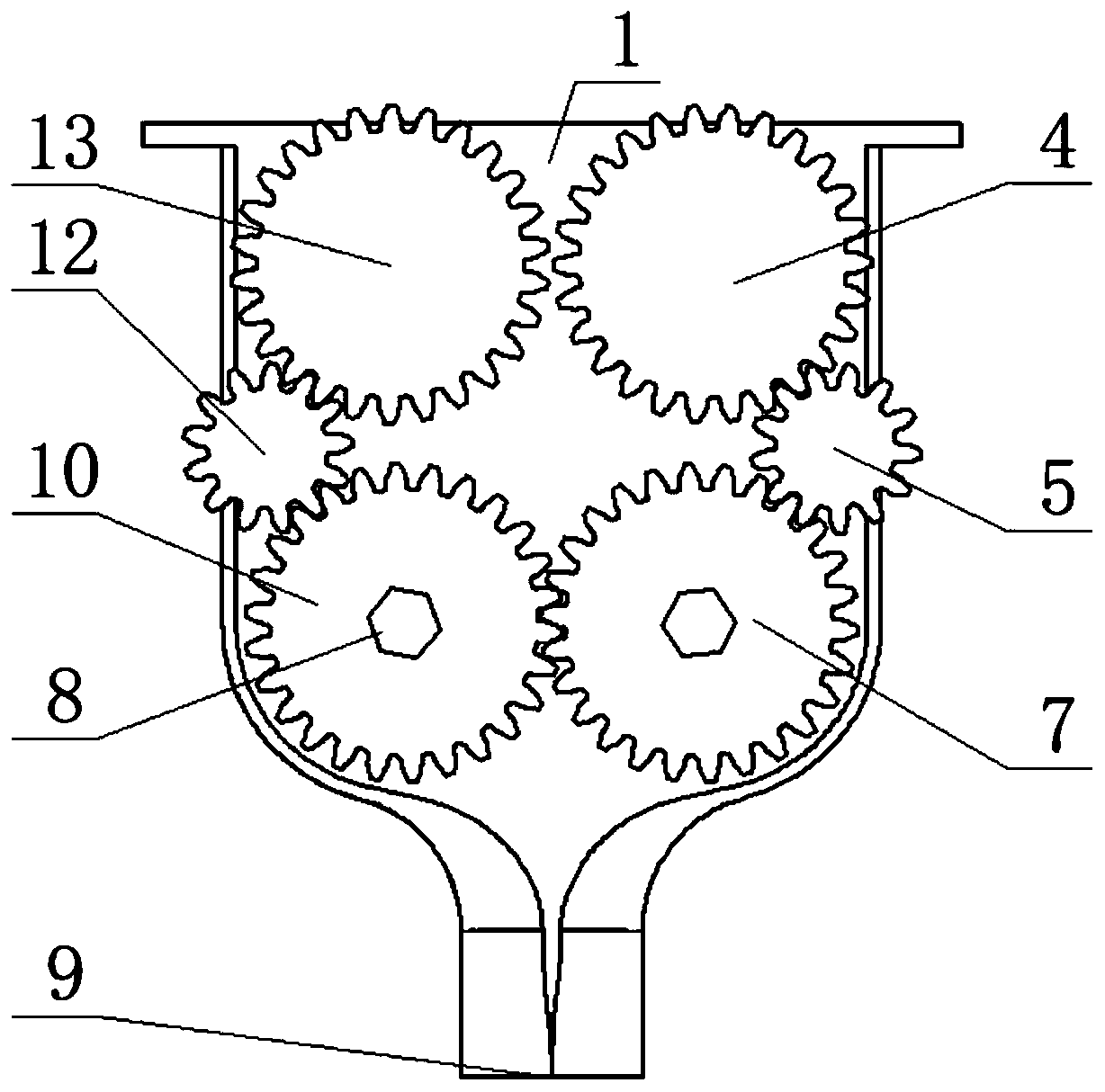

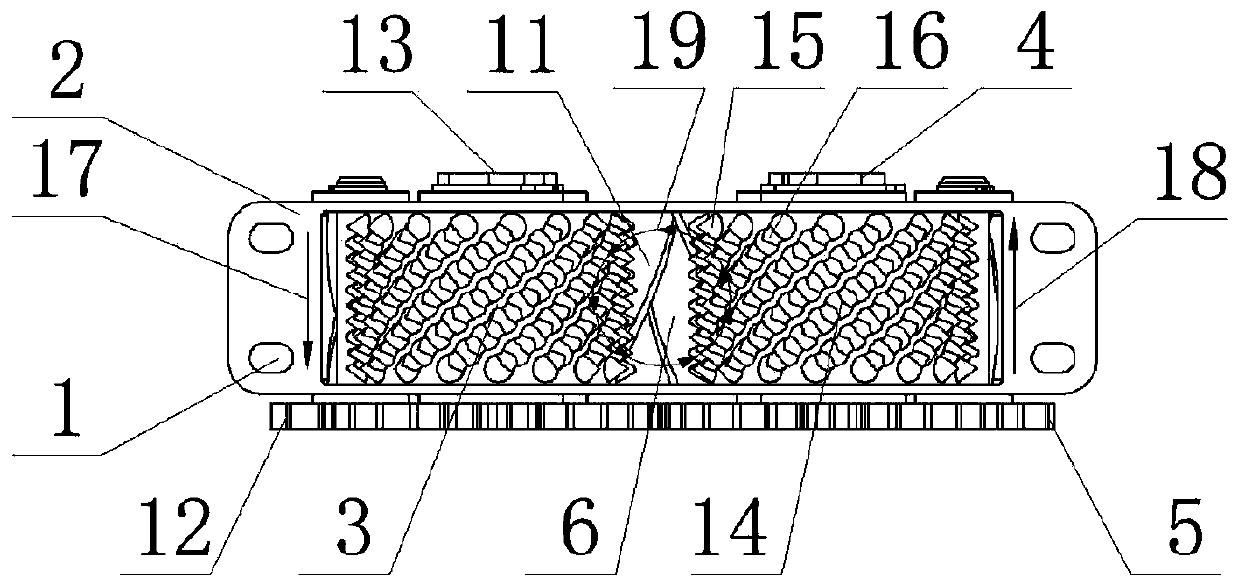

[0012] Below in conjunction with accompanying drawing, the embodiment that the present invention creates is described in detail:

[0013] A broken, anti-blocking and evenly applied fertilizer discharger with multi-stage crushing function, the housing 2 with installation holes 1 on the upper part of both sides can be rotated from bottom to top to assemble the left and right drive gear shafts 7 and 10, and the left and right transition gear shafts 5 , 12 and left and right driven gear shafts 4,13, left and right drive gear shafts 7,10 meshing with each other pass motion to left and right driven gear shafts 4, 10 through left and right transition gear shafts 5,12 respectively 13. The left and right driving gear shafts 7 and 10 with hexagonal holes 8 inside are respectively fixed in the middle parts of the left and right involute fertilizer discharge gears 6 and 11, and the left and right driven gear shafts 4 and 13 are fixed in the middle parts The right-handed cone ridge crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com