Gas layer reducing resistance type physical simulation testing device and testing method thereof

A physical simulation and testing device technology, applied in the field of fluid resistance measurement, can solve the problems of cumbersome operation, large investment, and long construction period, and achieve the effects of simplified installation procedures, large investment, and long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] see figure 1 , Figure 3 to Figure 7 As shown, what this embodiment provides is a physical simulation test device for air film drag reduction in a water tunnel, including a water supply system, a water tunnel system and a force measurement system; the water supply system includes a pool 1, a high-pressure water storage tank 13, a high-pressure Air storage tank 5, water pump 2 and air compressor 3, water pump 2 draws water source from pool 1, high-pressure water storage tank 13 stores water, on the pipeline that water pump 2 and high-pressure water storage tank 13 are connected, check valve 6 is arranged, The high-pressure water storage tank 13 is provided with a water storage tank safety valve 11 and a water storage tank pressure control switch 12, the high-pressure water storage tank 13, the high-pressure gas storage tank 5 and the air compressor 3 are connected in sequence, and the air compressor 3 works to Compressed air is injected into the high-pressure gas storag...

Embodiment 2

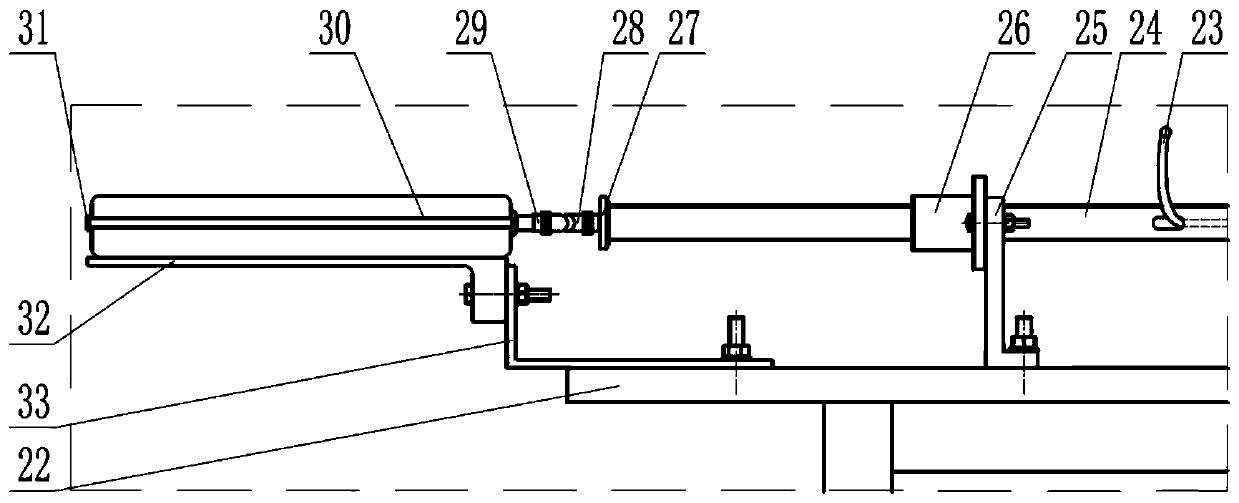

[0052] see Figure 2 to Figure 7 As shown, what this embodiment provides is a physical simulation test device for air film drag reduction in a wind tunnel, including an air supply system, a wind tunnel system, and a force measurement system; the air supply system includes a high-pressure water storage tank 13, a high-pressure storage tank Air tank 5, air compressor 3, close the air inlet valve 6 of high-pressure water storage tank 13, air compressor 3 works, squeeze into compressed air in high-pressure air storage tank 5, and high-pressure air storage tank 5 is provided with gas storage Tank safety valve 8 and air storage tank pressure control switch 7, store compressed air in high-pressure water storage tank 13; The tunnel system is fixed on the mounting frame 22 through the front support 16 and the rear support 19, the air inlet of the wind tunnel system is connected with the water outlet of the high-pressure water storage tank 13, and a diversion grid is set at the air inle...

Embodiment 3

[0061] The difference from Embodiment 1 and Embodiment 2 is that this embodiment uses two air-bearing linear bearings to replace the bearing support 25, the first linear bearing (not shown in the figure) and the second linear bearing 26. For floating linear bearing structure, please refer to Figure 8 As shown, it includes an end cover 34, a porous material 35, an air pipe joint 36, an end cover fastening screw 37 and a support 38, and an air bearing linear bearing is used to support the dowel bar 24, eliminating the influence of friction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com