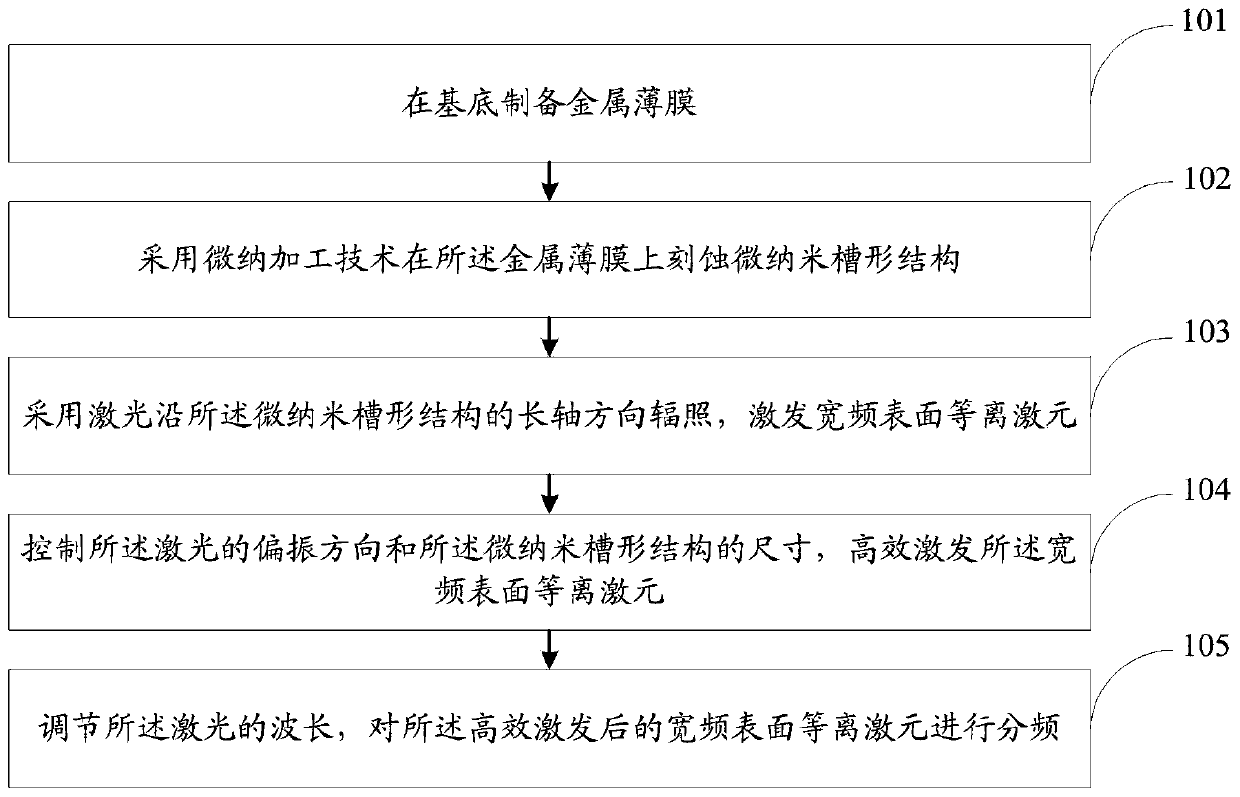

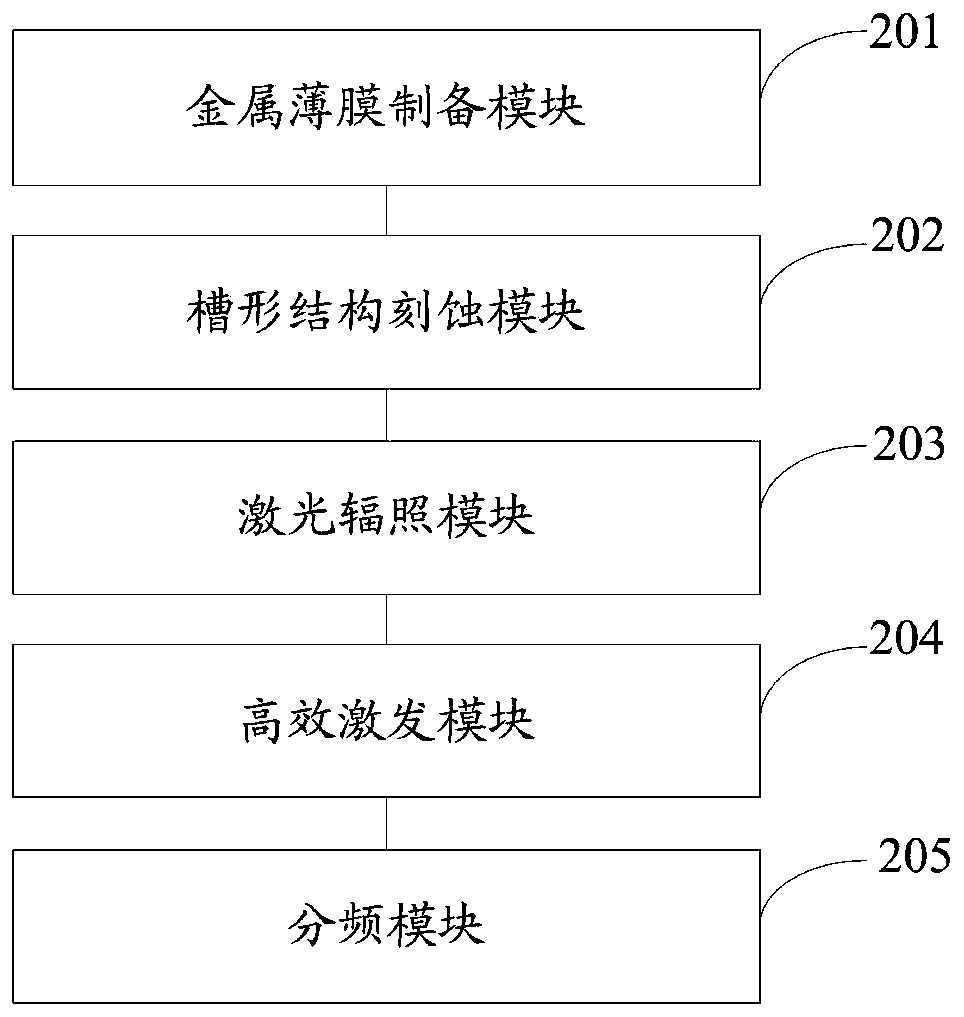

Method and system for realizing tunable surface plasmon polariton frequency division

A surface plasmon and broadband technology, applied in the field of plasmon frequency division, can solve the problems that tunable plasmon frequency division components have not been realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

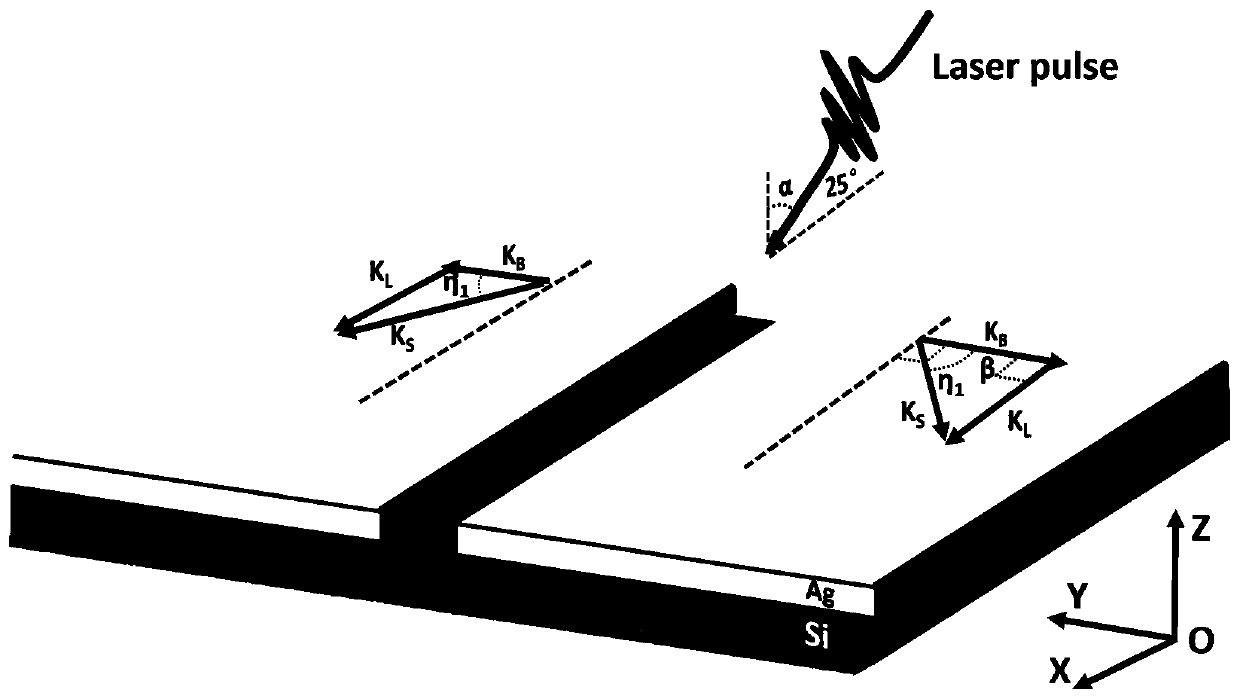

[0070] 1. Using femtosecond pulsed laser radiation with a center wavelength of 400nm to etch the surface of the silver thin film with micro-nano groove structure, the size of the groove structure is 1×40 μm and 1×20 μm. The laser spot completely covers the groove structure and the horizontal projection of the wave vector of the incident light is along the long axis (x axis) of the groove structure. Such as image 3 , image 3 It is a schematic diagram of a femtosecond pulsed laser irradiating on the surface of a silver nanofilm with a groove-shaped structure etched.

[0071] image 3 Medium K S Represents the wave vector of the SPP, whose direction is consistent with the propagation direction of the SPPs, K L is the component of the incident light wave vector projected on the sample surface, K B is the "wave vector" of the interference signal in the PEEM image.

[0072] 2. By adjusting the polarization direction of the incident laser and controlling the groove structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com