Simple and feasible scanning electrochemical microscope test method

A scanning electrochemistry and testing method technology, applied in the direction of material electrochemical variables, etc., can solve the problems of scanning electrochemical microscope work electricity difficulty, test sample damage, etc., to avoid electrolyte leakage, sample fast, easy to install and disassemble samples Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention provides a simple and easy scanning electrochemical microscope testing method.

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

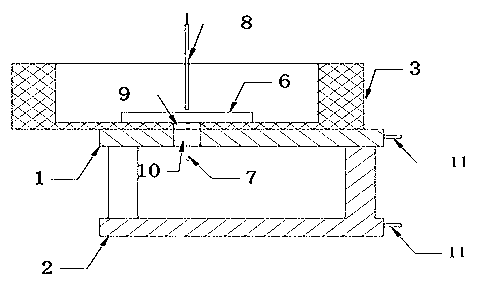

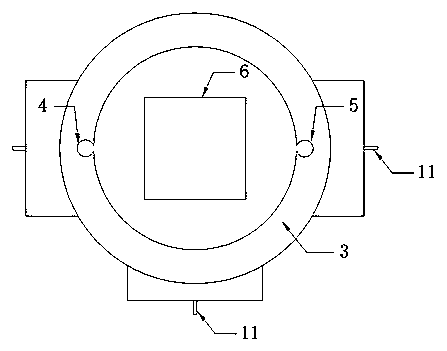

[0023] As shown in the accompanying drawings, 1 is the loading plate, 2 is the instrument base, 3 is the improved electrolytic cell, 4 is the round hole for placing the counter electrode, 5 is the round hole for placing the reference electrode, and 6 is the The test sample is the working electrode, 7 is a wire, 8 is a probe used for scanning, 9 is a round hole opened in the center of the bottom surface of the electrolytic cell, 10 is a round hole at the center of the loading plate 1, and 11 is a small cylindrical rod.

[0024] The use of hot melt adhesive is fast curing, pollution-free, pollution-free, non-toxic, strong adhesion, the adhesive layer has a certain degree of flexibility, hardness, and certain toughness, can be bonded and solidified in a few seconds, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com