Method for regulating and controlling F-P optical fiber sensor sensitivity through intracavity gas pressure

A technology of optical fiber temperature and gas pressure, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of inability to control temperature test sensitivity, inability to achieve high-sensitivity test temperature, etc., to achieve easy implementation and simple method , the effect of improving the degree of perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

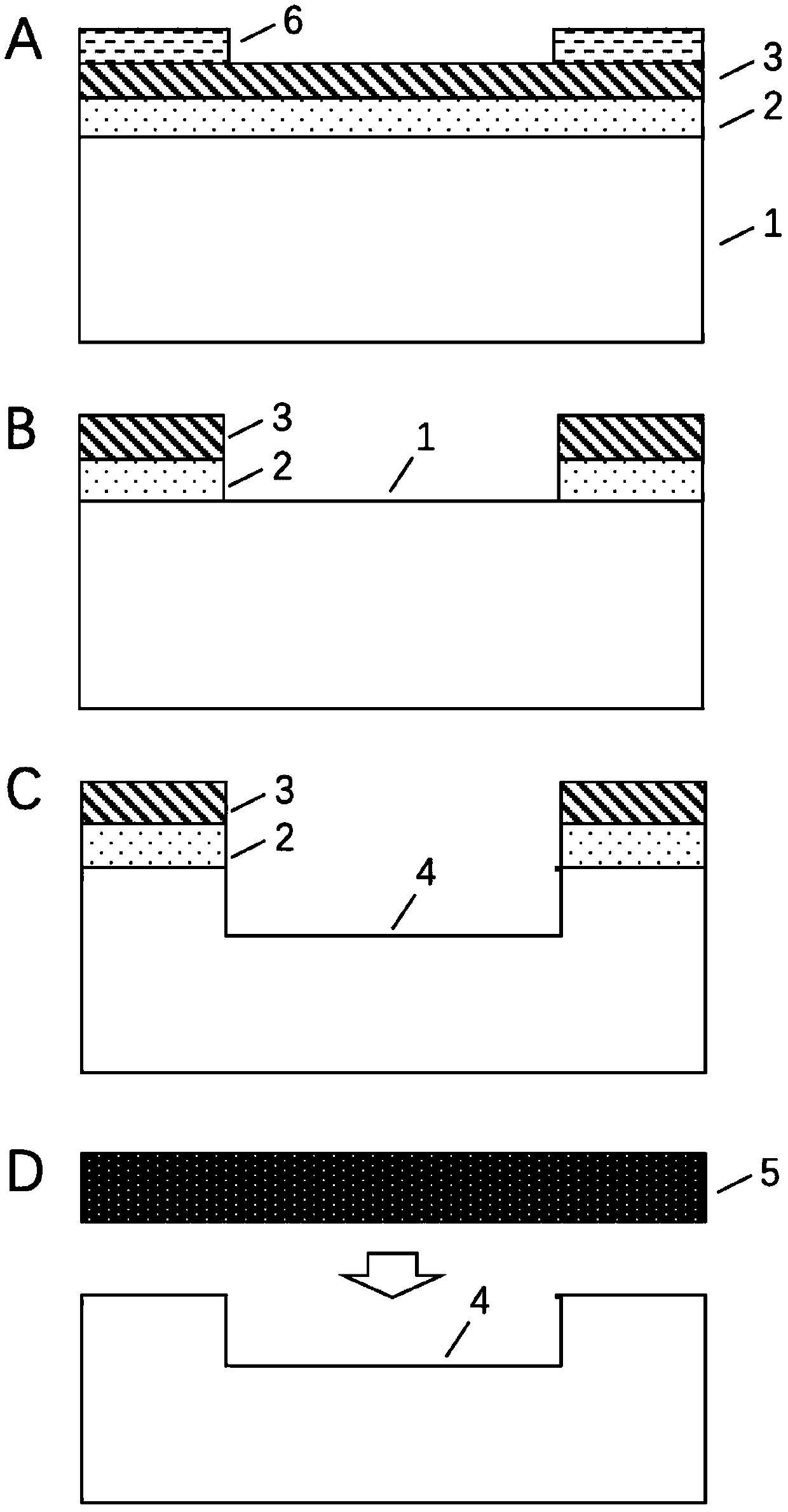

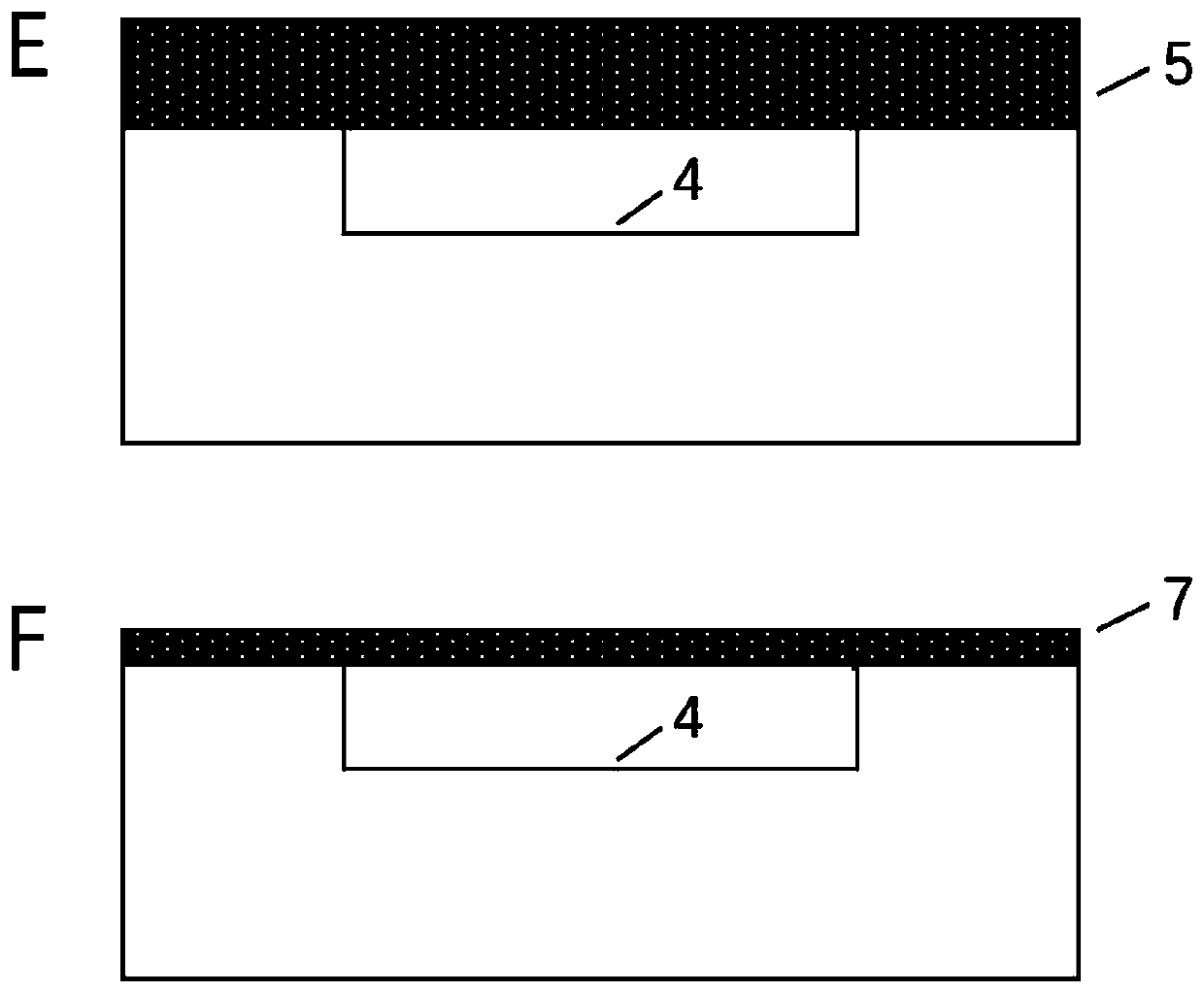

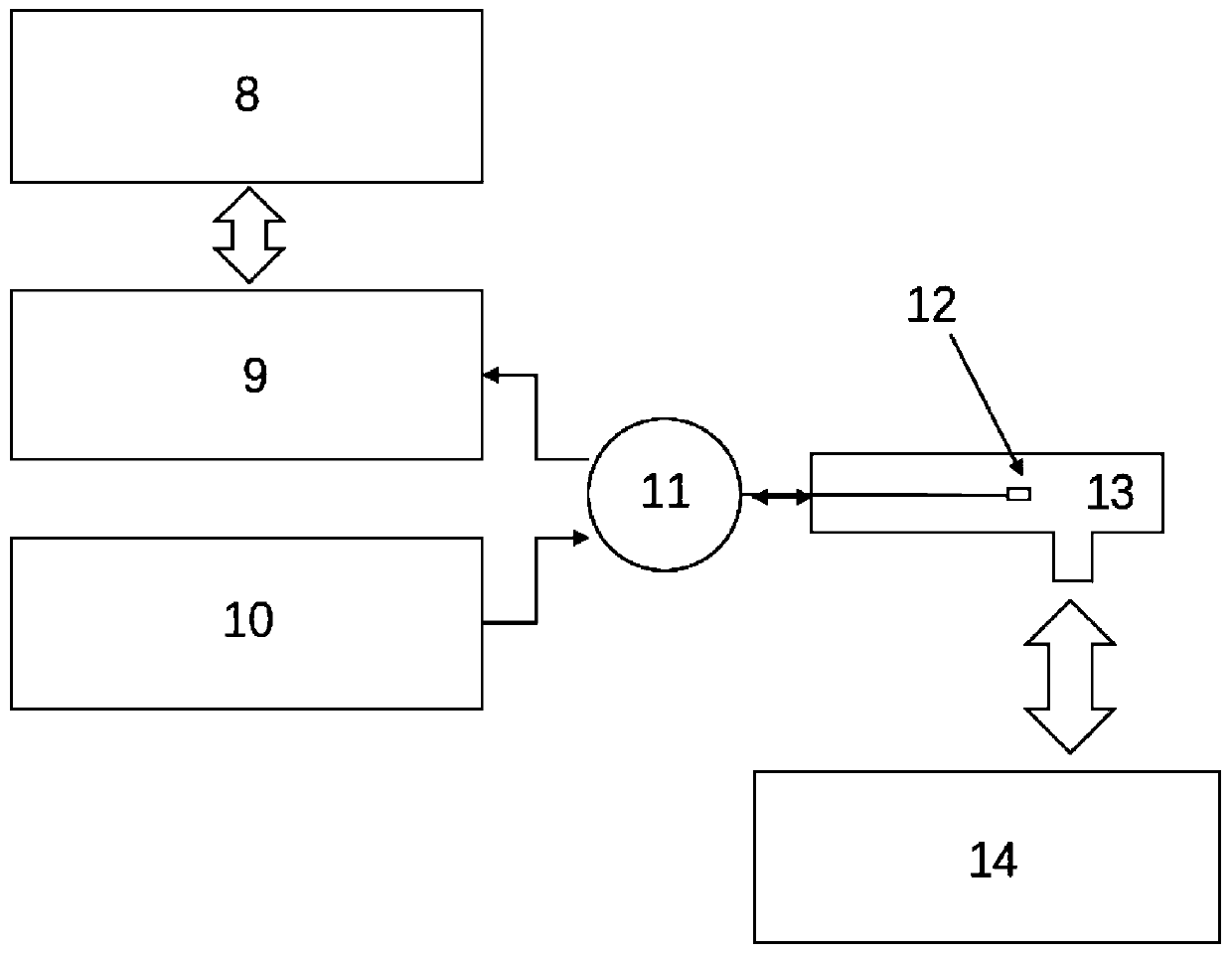

[0046] A method for regulating the sensitivity of an F-P optical fiber temperature sensor through gas pressure in a cavity, comprising the following steps, the process steps are as follows figure 1 Shown:

[0047](1) successively sputtering thickness is the Ni film 2 of 200nm and the Au film 3 of 800nm on the surface of borosilicate glass 1, forms Ni / Au alloy thin film; Layer photoresist positive resist (AZ1500) 6, then align the photoresist plate for exposure and development, and put it into the positive resist developer to wash off the excess; as figure 1 a.

[0048] The patterned borosilicate glass is etched with Au etching solution and Ni etching solution successively, and the etching time is 5 minutes and 1 minute respectively; the Au etching solution is iodine, potassium iodide, water in a mass ratio of 1:5:20 Mixed solution; the Ni corrosion solution is hydrochloric acid with a mass fraction of 10%. After etching, wash off the photoresist mask with acetone to form ...

Embodiment 2

[0053] With the method for regulating the sensitivity of the F-P optical fiber temperature sensor by the gas pressure in the cavity described in Example 1, the difference is that:

[0054] Step (2) During the bonding process, adjust the pressure of the vacuum chamber of the bonding furnace so that the pressure of the vacuum chamber is 0.02 MPa, and prepare a sample with a pressure of 0.02 MPa in the sealed cavity between the silicon wafer and the borosilicate glass.

Embodiment 3

[0056] With the method for regulating the sensitivity of the F-P optical fiber temperature sensor by the gas pressure in the cavity described in Example 1, the difference is that:

[0057] Step (2) During the bonding process, adjust the pressure of the vacuum chamber of the bonding furnace so that the pressure of the vacuum chamber is 0.03 MPa, and prepare a sample with a pressure of 0.03 MPa in the sealed cavity between the silicon wafer and the borosilicate glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com