Horizontal-opposed diaphragm type electric vacuum pump

An electric vacuum pump, horizontally opposed technology, applied in variable capacity pump components, pumps, pump components, etc., can solve problems such as pedal sinking, brake vacuum booster damage, etc., to meet braking performance and reduce volume , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

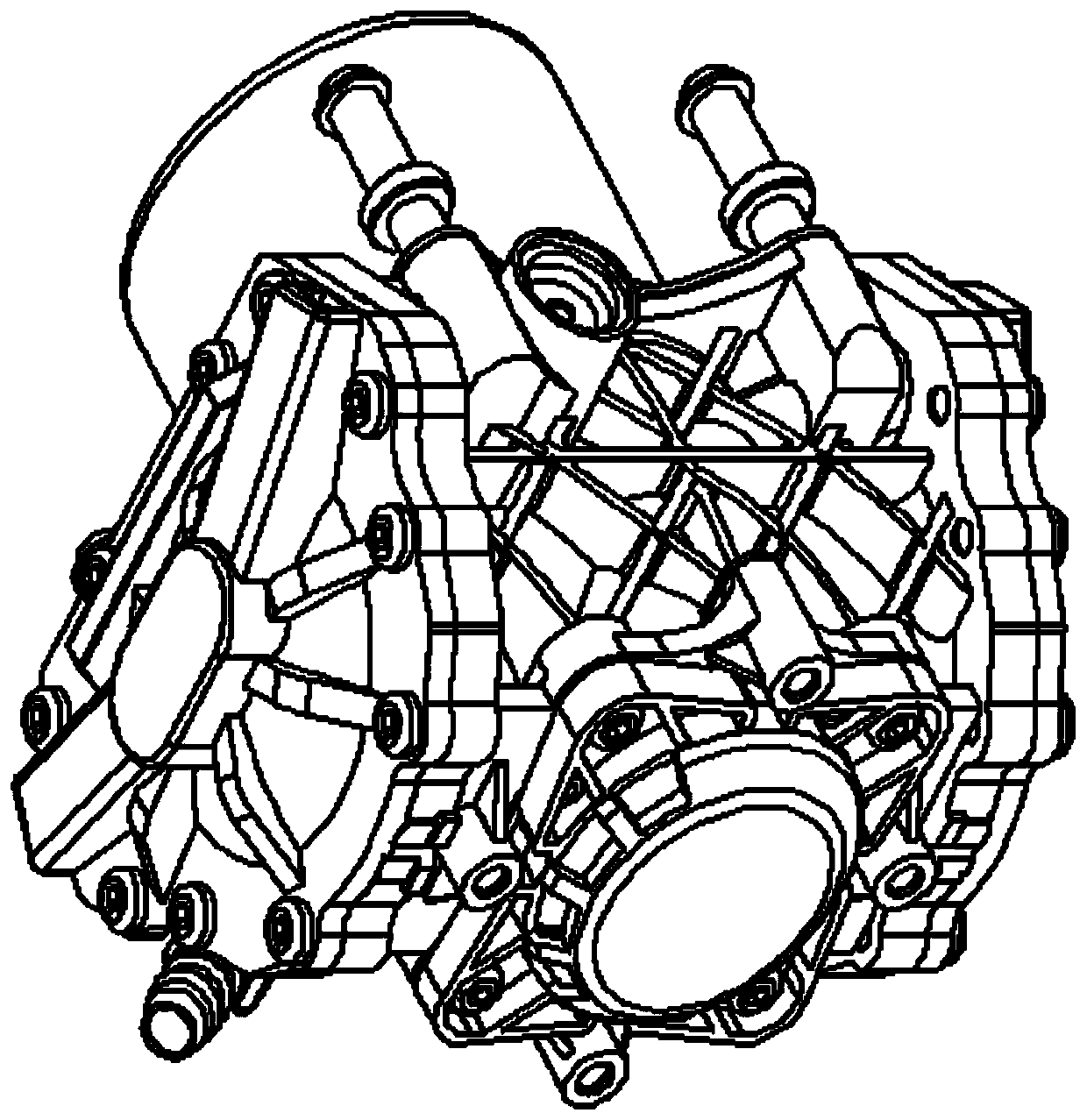

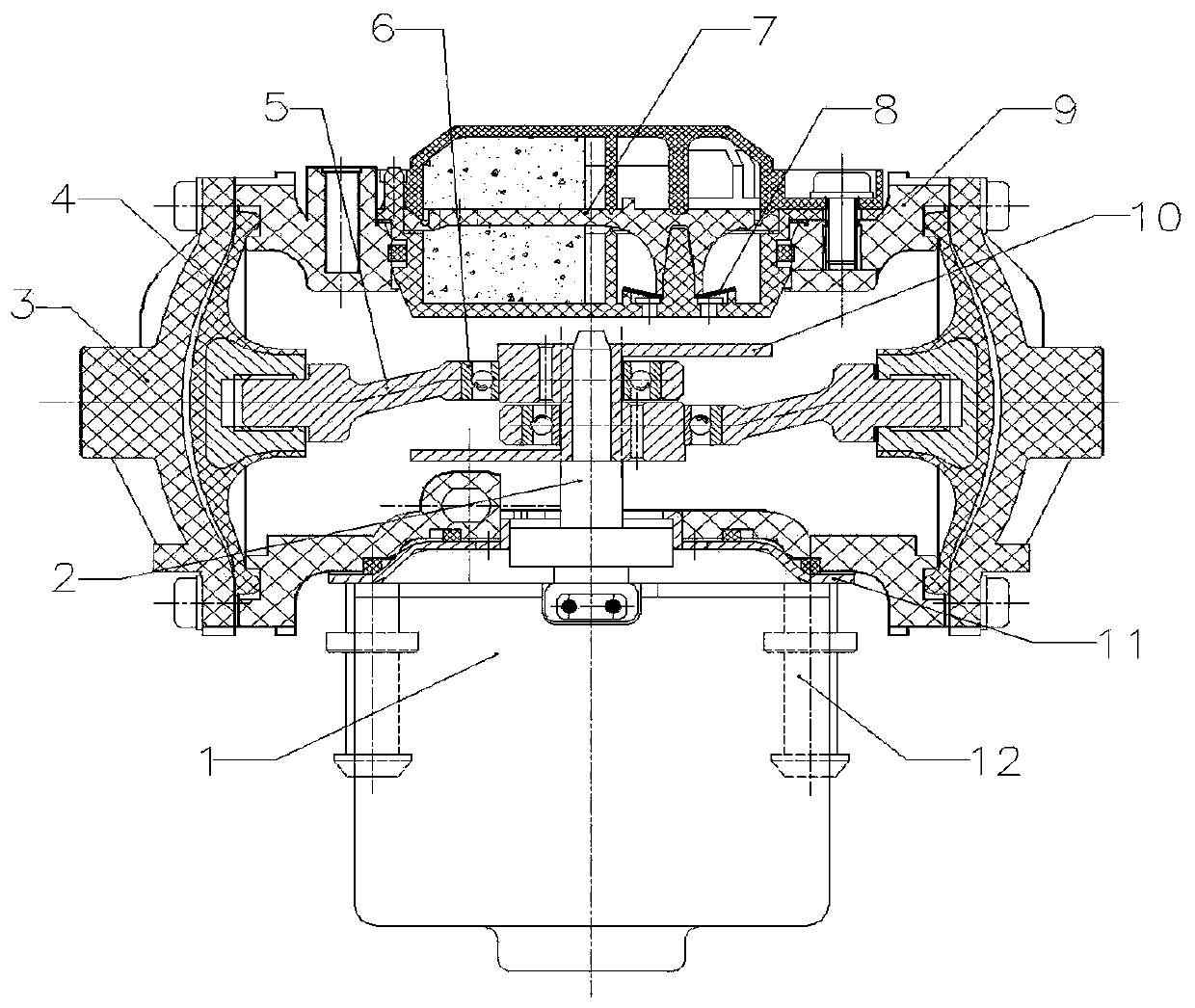

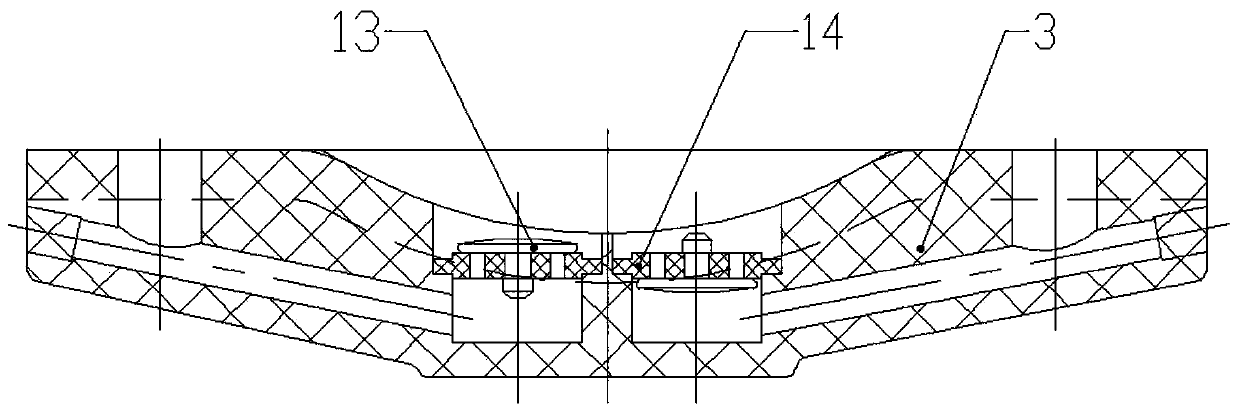

[0031] The technical solutions of the present invention will be further described below through specific examples.

[0032] like Figure 1-Figure 4 A horizontally opposed diaphragm type electric vacuum pump is shown, including a pump body 9, a DC motor 1, a motor shaft 2, a linkage assembly, an end cover 3 and a diaphragm assembly 4, and a reinforced nylon injection-molded pump body 9, reinforced nylon injection-molded and The end cover 3 with the air passage inside, the linkage assembly includes the connecting rod assembly, the bearing 6 and the eccentric crank 10, the eccentric crank 10 is connected with the motor shaft 2, the end cover 3 is provided on both sides of the pump body 9, and the DC motor 1 is set At the bottom of the pump body 9, the DC motor 1 is connected to the eccentric crank 10 through the motor shaft 2 to drive its movement, the eccentric crank 10 is connected to the connecting rod assembly 5 through the bearing 6, the connecting rod assembly 5 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com