Fluid infusion machine, starch jet-cooking equipment, starch liquefaction device, and high-concentration starch milk jet-cooking and liquefying method

A technology of jet cooking and starch liquefaction, which is applied in the directions of biochemical equipment and methods, biochemical cleaning devices, biological material sampling methods, etc., to achieve the effects of saving energy consumption, improving efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

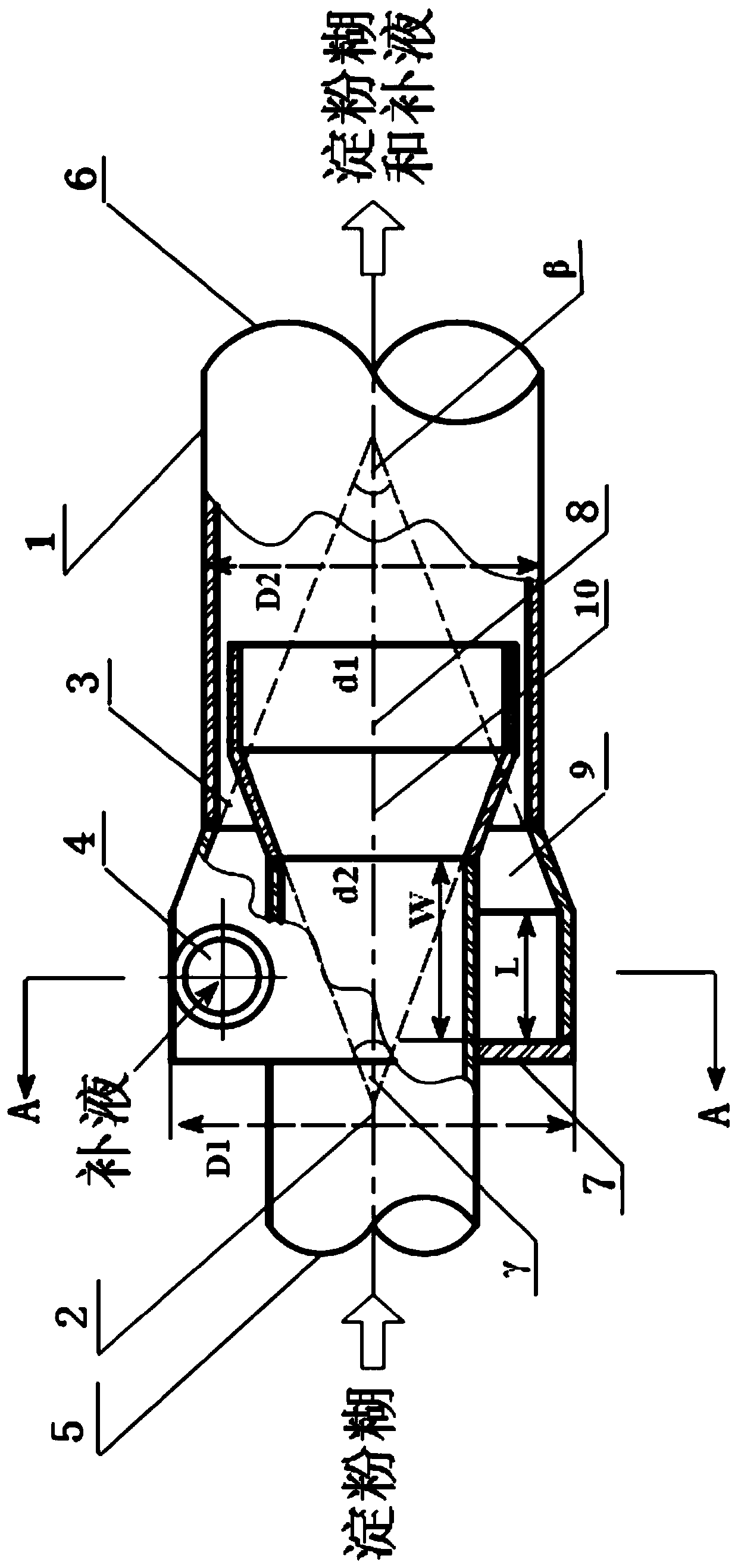

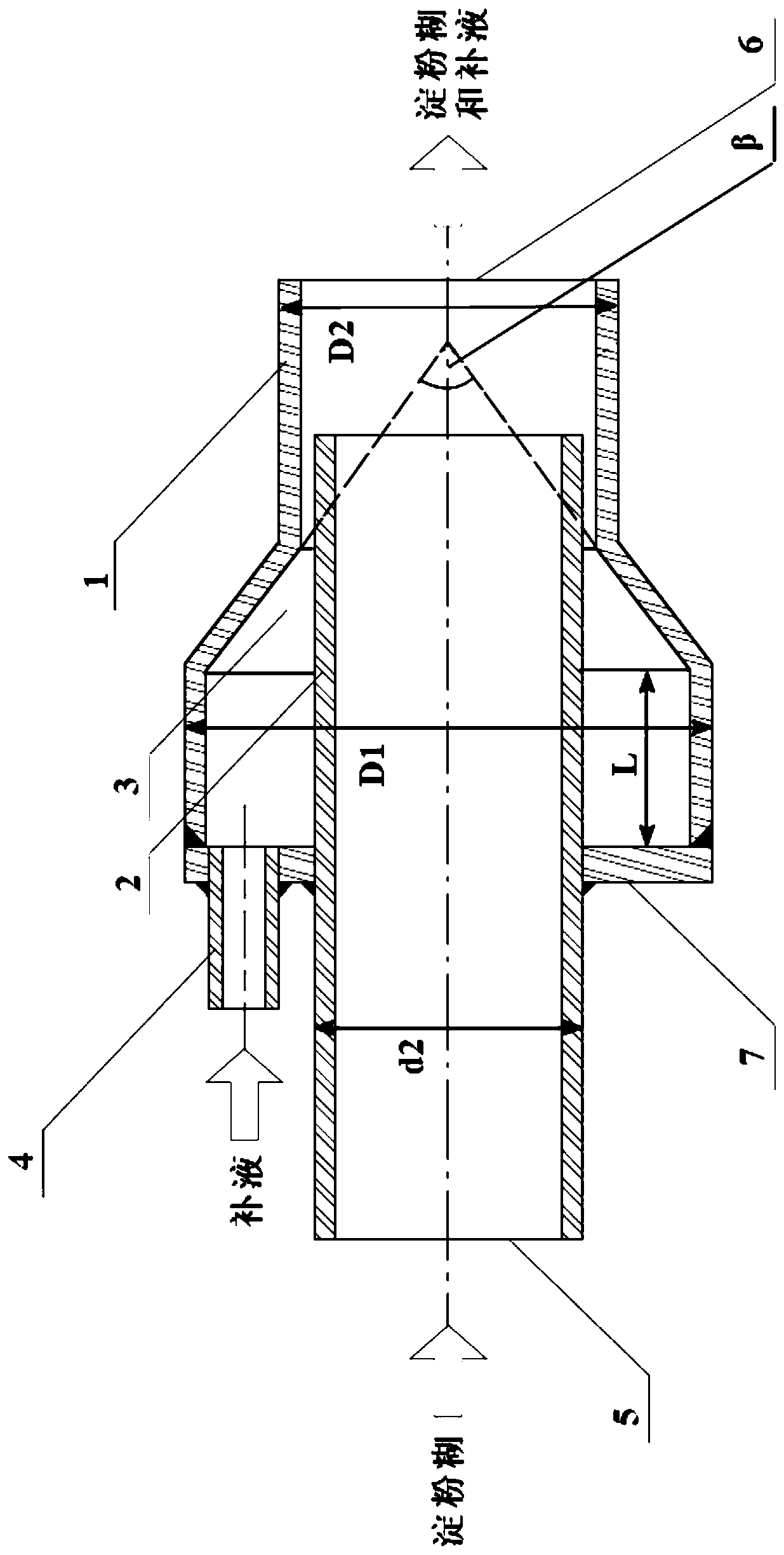

[0056] On the starch liquefaction device provided by the present invention, it includes figure 1 and 2 The jet cooking equipment of the liquid replenisher shown is used to produce starch liquefaction liquid from high-concentration starch milk.

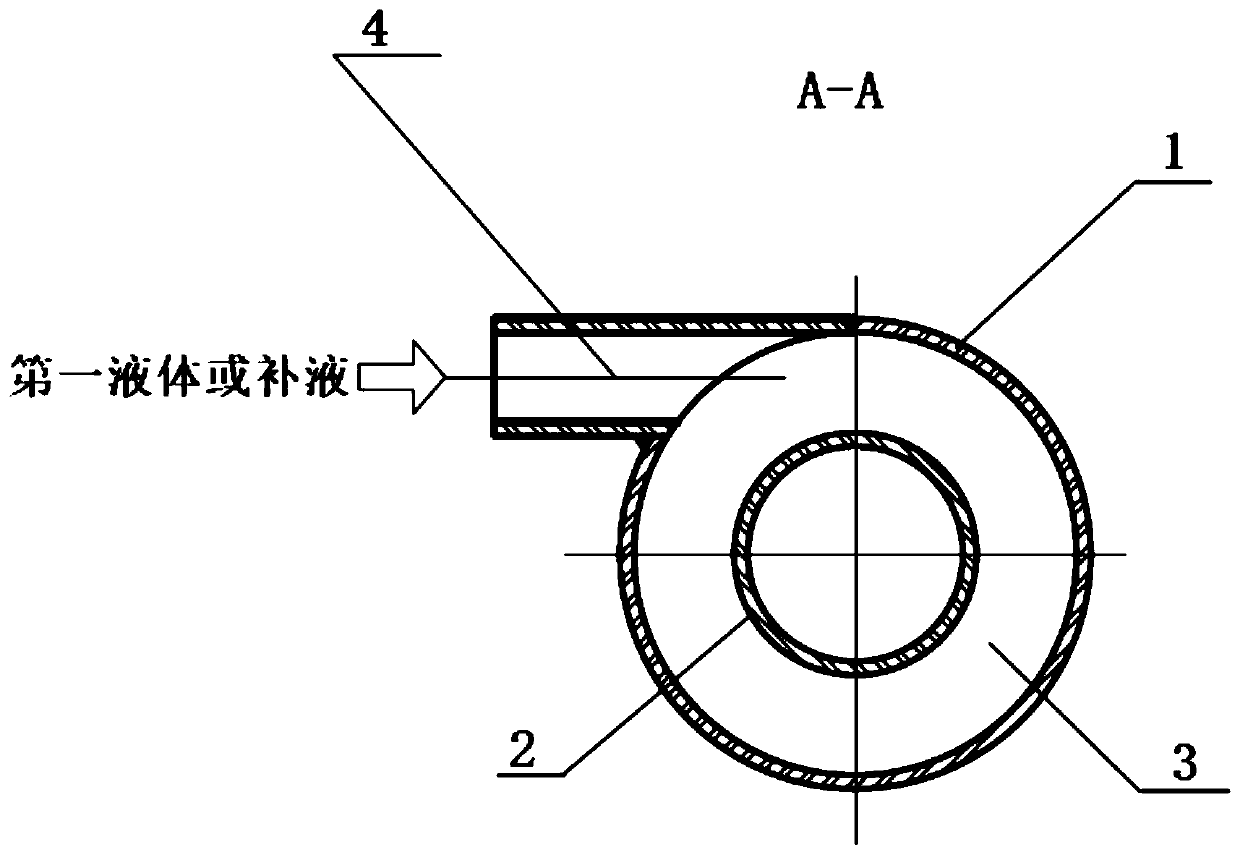

[0057] Among them, the inner diameter of the inlet of the liquid replacement device is 32mm, the outer diameter is 38mm (i.e. d2), the inner tube is expanded to an inner diameter of 42mm, and an outer diameter is 52mm (i.e. d1), and the cone angle γ of the enlarged diameter section is 42 °, the distance W is 30 mm; the outer tube is reduced in diameter through the reducing section, the outer diameter D1 is reduced from 76mm to D2 is 62mm, and the cone angle β of the reducing section is 42°. The minimum radial width of the radial gap formed between the inner tube and the outer tube is 0.4mm. The length L is 20 mm. The inner diameter of the liquid replenishing tube is 6mm, and it is arranged along the tangential direction of the outer...

Embodiment 2

[0065] According to the method of Example 1, the difference is that "30 L / h of soft water in the replenishment storage tank" is used instead of "30 L / h of sweet water in the replenishment storage tank".

[0066] Evaluate the liquefaction effect. The results are shown in Table 3.

[0067] table 3

[0068]

[0069] As can be seen from the results in Table 3, in Example 2, by adopting the method and equipment provided by the present invention, a small amount of hot soft water is tangentially injected into the radial gap of the liquid replenisher at a flow rate of 3% of the volume flow rate of the feed amount. When the dry starch content in the feed starch milk is as high as 45%, the starch milk jet cooking liquefaction system can still operate normally, and the filtration speed of the liquefaction liquid obtained after the system is still slightly faster than that of the comparative example. The filtration rate of the obtained liquefied liquid at 34% shows that the liquefied...

Embodiment 3

[0071] On the starch liquefaction device provided by the present invention, it includes figure 1 and 2 The jet cooking equipment of the liquid replenisher shown is used to produce starch liquefaction liquid from high-concentration starch milk.

[0072] Among them, the inner diameter of the inlet of the liquid replacement device is 32mm, the outer diameter is 38mm (i.e. d2), the inner tube is expanded to an inner diameter of 42mm, and an outer diameter is 52mm (i.e. d1), and the cone angle γ of the enlarged diameter section is 60 °, the distance W is 30 mm; the outer tube is reduced in diameter through the reducing section, the outer diameter D1 is reduced from 76mm to D2 is 63mm, and the cone angle β of the reducing section is 60°. The minimum radial width of the radial gap formed between the inner tube and the outer tube is 0.8mm. The length L is 20 mm. The inner diameter of the liquid replenishing tube is 6mm, and it is arranged along the tangential direction of the outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com