Preparation of high concentration SnS2 nanosheet with liquid phase stripping method

A liquid phase exfoliation and nanosheet technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of many surface defects, small nanosheet area, poor crystallinity, etc., to avoid agglomeration, high exfoliation rate, High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

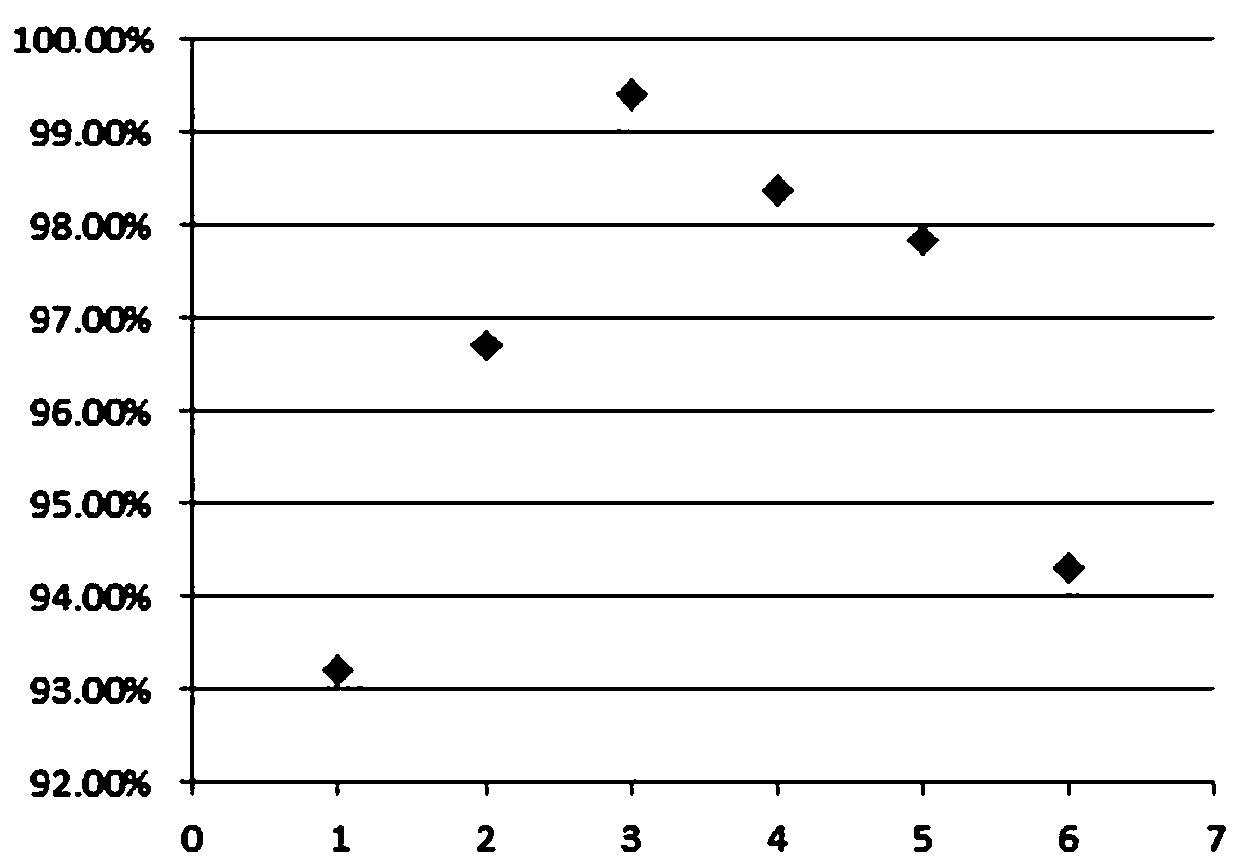

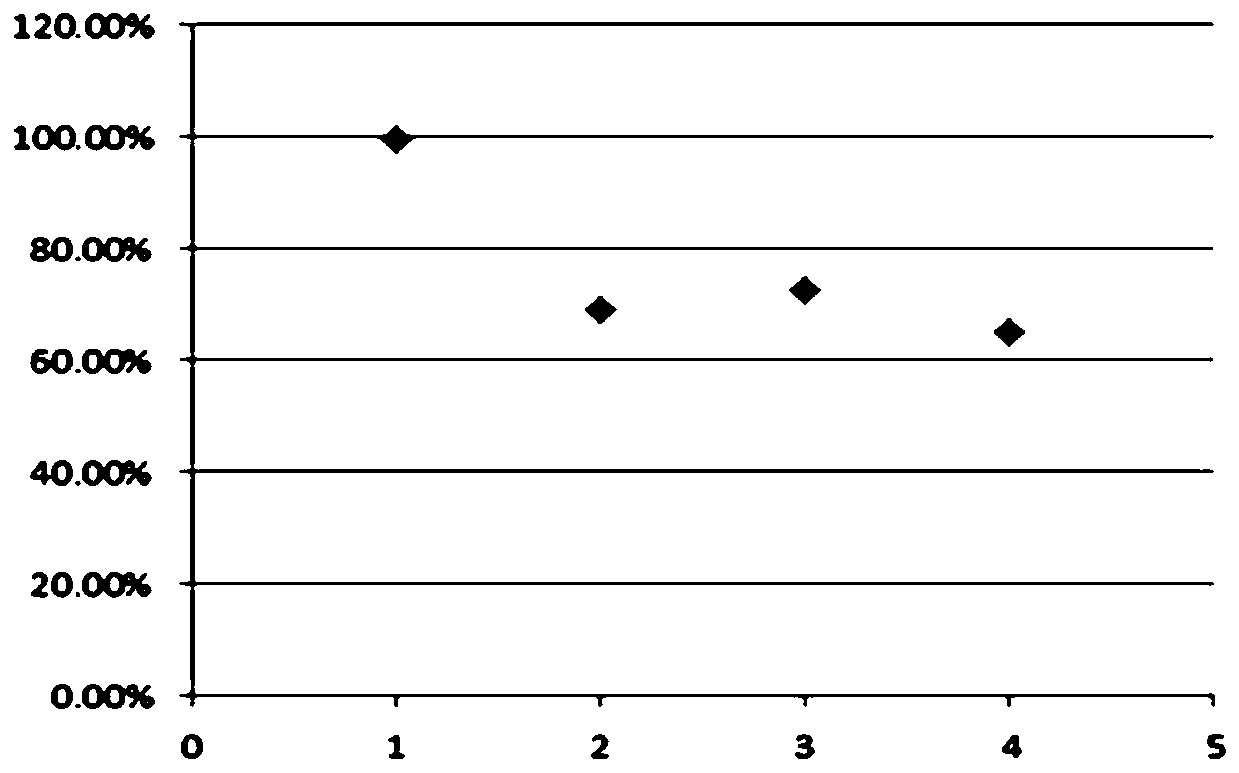

Image

Examples

Embodiment 1

[0048] A liquid phase exfoliation method for preparing high-concentration SnS2 nanosheets, specifically comprising the following steps: Step S1: adding 5 g of tin disulfide polycrystalline powder with a particle size of 5-100 μm and a purity greater than 99.95% into a closed blue cap ultrasonic bottle In the blue cap ultrasonic bottle, add the volume fraction of 20% ethanol and 80% water mixed solvent 300ml to form a solution system;

[0049] Step S2: performing ammonia gas bubbling treatment on the solution system in the blue cap ultrasonic bottle;

[0050] Step S3: Put the blue cap ultrasonic bottle into the ultrasonic cleaning machine for ultrasonic treatment. The conditions of ultrasonic treatment are: ultrasonic dispersion for 10 hours under the condition of 100W. The effect of obtaining orange yellow SnS2 nanosheet dispersion;

[0051] Step S4: Separating the orange yellow SnS2 nanosheet dispersion to obtain clean SnS2 nanosheets.

[0052] Wherein, the bubbling process...

Embodiment 2

[0067] The difference between this example and Example 1 lies in step S1: adding 5 g of tin disulfide polycrystalline powder with a particle size of 5-100 μm and a purity greater than 99.95% into a closed ultrasonic bottle with a blue cap, and then pouring Add 20% ethanol and 80% water mixed solvent 350ml into the ultrasonic bottle to form a solution system. All the other steps are the same as in Example 1.

Embodiment 3

[0069] The difference between this example and Example 1 lies in step S1: adding 5 g of tin disulfide polycrystalline powder with a particle size of 5-100 μm and a purity greater than 99.95% into a closed ultrasonic bottle with a blue cap, and then pouring Add 20% ethanol and 80% water mixed solvent 500ml into the ultrasonic bottle to form a solution system. All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com