Preparation method of surface-modified oil-soluble graphene oxide

A graphene and oil-soluble technology, which is applied in the field of preparation of new nano-functional materials, can solve problems such as process instability and production scale limitation, and achieve the effects of simple process equipment, long-term stable existence, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

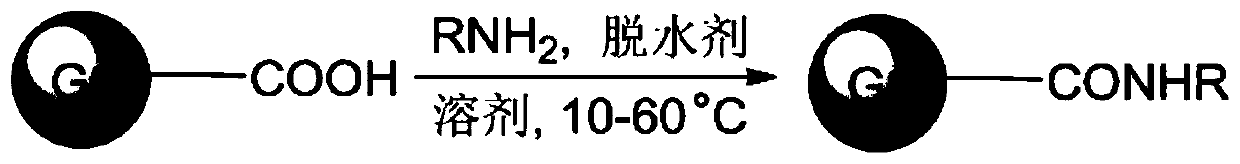

Method used

Image

Examples

Embodiment 1

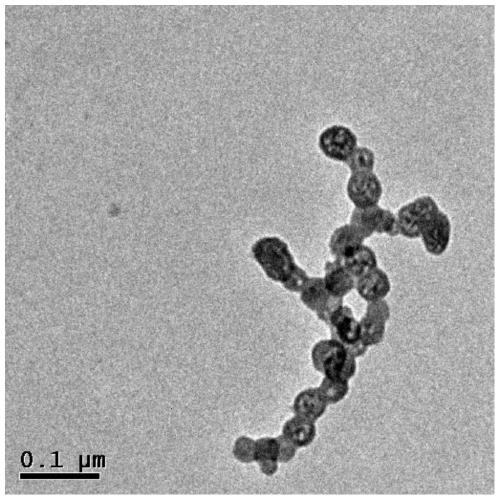

[0032] Add 3.00g of graphene oxide and 210mL of N,N-dimethylformamide (DMF) into a 1000mL fluorinated bottle, stir to disperse and dissolve on a high-speed mixer, and then crush in an ultrasonic crusher for 3h (power 350W). Transfer the solution into a 1000mL four-neck flask, add 1.00g dehydrating agent 1-ethyl-(3-dimethylaminopropyl) carbodiimide, 8.00g dicyclohexylcarbodiimide, 9.00g octadecyl Amine, stirred at 25°C for 24h. Stirring was stopped, the reaction solution was centrifuged, washed several times with deionized water, and freeze-dried to obtain modified oil-soluble graphene oxide. Its transmission electron microscope image is shown in figure 2 , as can be seen from the figure, the particle size distribution of the obtained product is uniform, and the average particle size is 50-100nm.

Embodiment 2

[0034] Add 3.00g of graphene oxide and 450mL of DMF into a 1000mL fluorinated bottle, stir to disperse and dissolve on a high-speed mixer, and then crush in an ultrasonic breaker for 3h (power 350W). Transfer the solution into a 1000mL four-neck flask, add 1.00g dehydrating agent 1-ethyl-(3-dimethylaminopropyl) carbodiimide, 8.00g dicyclohexylcarbodiimide, 9.00g octadecyl Amine, stirred at 25°C for 48h. Stirring was stopped, the reaction solution was centrifuged, washed several times with deionized water, and freeze-dried to obtain modified oil-soluble graphene oxide. Its transmission electron microscope image is shown in image 3 , as can be seen from the figure, the particle size distribution of the obtained product is uniform, and the average particle size is 20-80nm.

Embodiment 3

[0036] Add 3.00g of graphene oxide, 150mL of 1,2-dichloroethane (DCE), and 300mL of DMF into a 1000mL fluorinated bottle, stir to disperse and dissolve on a high-speed mixer, and then crush in an ultrasonic crusher for 3h (power 350W) . Transfer the solution into a 1000mL four-neck flask, add 1.00g dehydrating agent 1-ethyl-(3-dimethylaminopropyl) carbodiimide, 8.00g dicyclohexylcarbodiimide, 9.00g octadecyl Amine, stirred at 25°C for 48h. Stirring was stopped, the reaction solution was centrifuged, washed several times with deionized water, and freeze-dried to obtain modified oil-soluble graphene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com