Multistage diamond micro-powder selecting machine

A technology of diamond micropowder and type selection machine, which is applied in solid separation, sieve, grid and other directions, can solve the problem of affecting the precision and efficiency of the selection of fine steel stone powder, affecting the precision and efficiency of the type selection operation, pitting In order to improve the efficiency of fault removal and repair work, the selection accuracy and work efficiency are high, and the stability is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

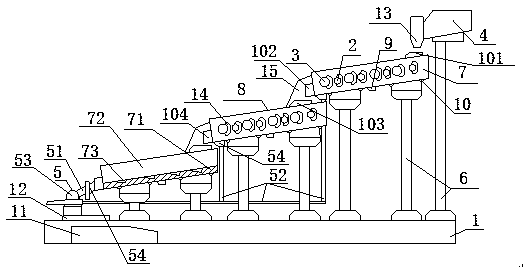

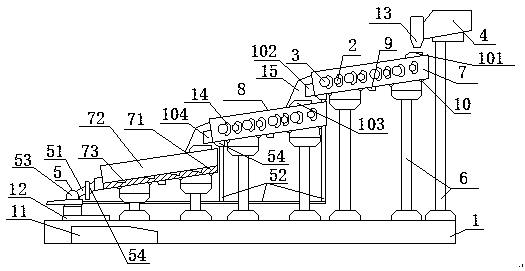

[0020] Such as figure 1The multi-stage diamond powder selection machine includes a bearing base 1, an electromagnetic oscillation device 2, an ultrasonic oscillation device 3, an upper material cylinder 4, a discharge trough 5, an electric telescopic column 6, a main sorting disc 7, The secondary sorting disc 8, the inclination sensor 9, the vibration sensor 10 and the control system 11, wherein the bearing base 1 is a frame structure with the axis and the horizontal plane vertically distributed, and a number of electric telescopic columns 6 are evenly distributed on the upper end surface, and the electric telescopic columns 6 and the main sorting disc 7, the lower end surfaces of the secondary sorting disc 8 are connected to each other, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com