Structure of foamed asphalt cold-recycled pavement and construction technology thereof

A foamed asphalt and pavement structure technology, applied to roads, roads, other household appliances, etc., can solve the problems of not taking into account the anti-freezing effect of roads, construction difficulties, etc. The effect of prolonging the effective time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

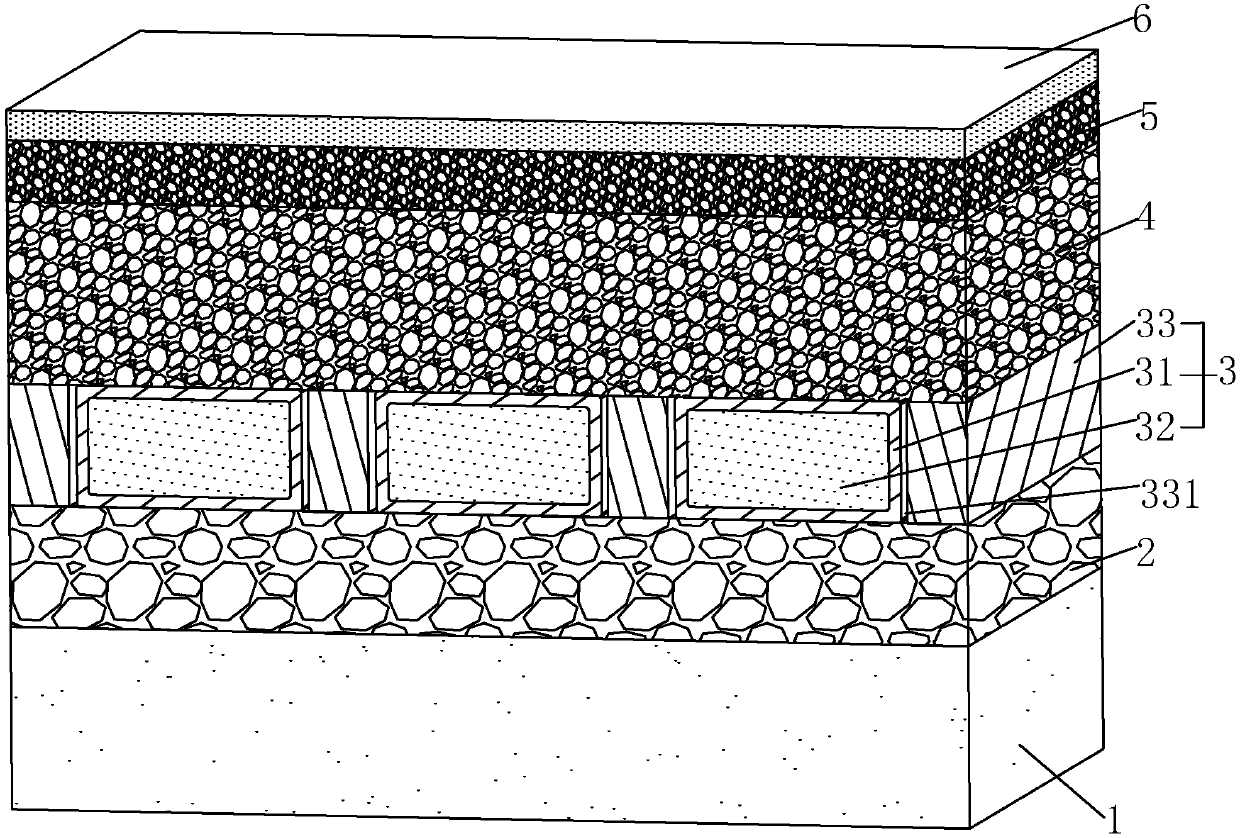

[0060] A foamed asphalt cold recycled pavement structure, such as figure 1 As shown, from bottom to top, it includes a reinforcement layer 2, a protective layer 3, a recycled asphalt concrete layer 4 and an asphalt concrete layer 5 laid on the soil base 1; wherein the raw material of the reinforcement layer 2 is a mixture of gravel and cement; the protection Layer 3 comprises a layer 32 of calcium oxide and a layer 31 of biodegradable plastic encapsulating the layer 32 of calcium oxide. The biodegradable plastic layer 31 is formed by a biodegradable plastic bag, and the calcium oxide is contained in the biodegradable plastic bag and packaged, so the protective layer 3 includes the biodegradable plastic layer 31, the calcium oxide layer 32, and the biodegradable plastic layer from bottom to top. Layer 31. The calcium oxide layer 32 of the protective layer 3 is encapsulated with a biodegradable plastic layer 31 to prevent the calcium oxide from getting wet during construction. ...

Embodiment 2

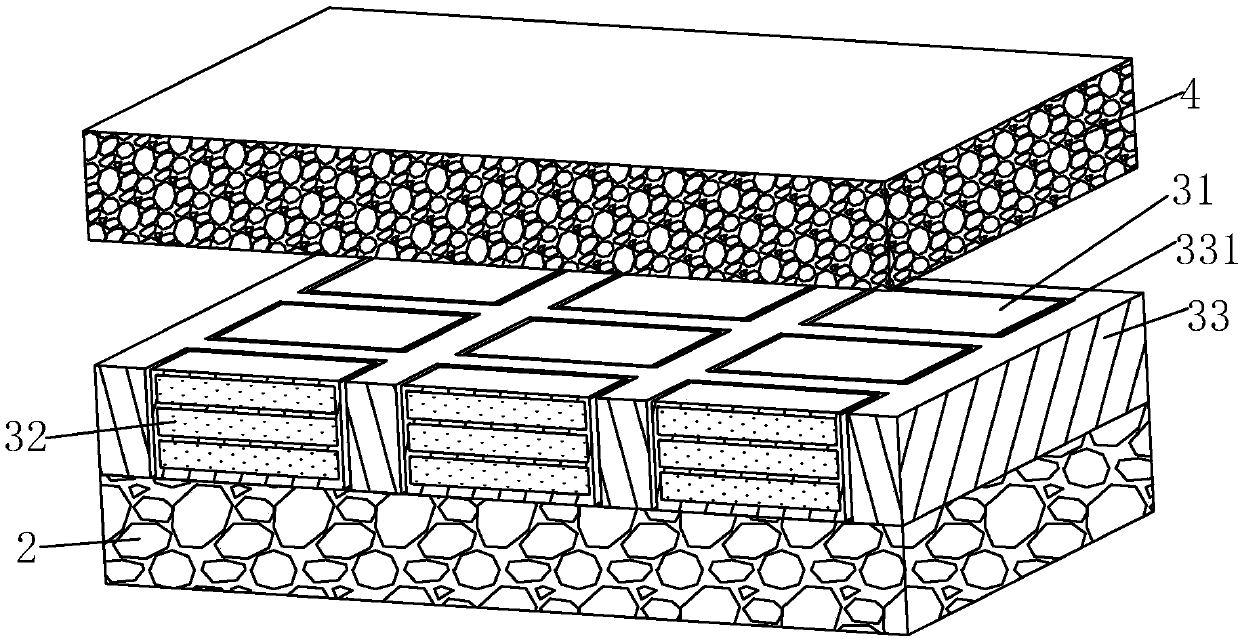

[0074] A foamed asphalt cold recycled pavement structure, such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that the calcium oxide layer 32 and the biodegradable plastic layer 31 are alternately arranged in multiple layers. The protective layer 3 includes a biodegradable plastic layer 31 , a calcium oxide layer 32 , a biodegradable plastic layer 31 , a calcium oxide layer 32 , and a biodegradable plastic layer 31 from bottom to top. Calcium oxide is set in multiple layers, and the relative amount increases, which can react with more water and release more heat, which improves the anti-freeze cracking ability of the pavement and prolongs the anti-freeze cracking time of the pavement. And the construction is also more convenient. In other embodiments, a layer of garbage compost can also be laid on the top layer. Garbage compost can accelerate the degradation of biodegradable plastics, allowing the top layer of biodegradable plastics to degrade ...

Embodiment 3

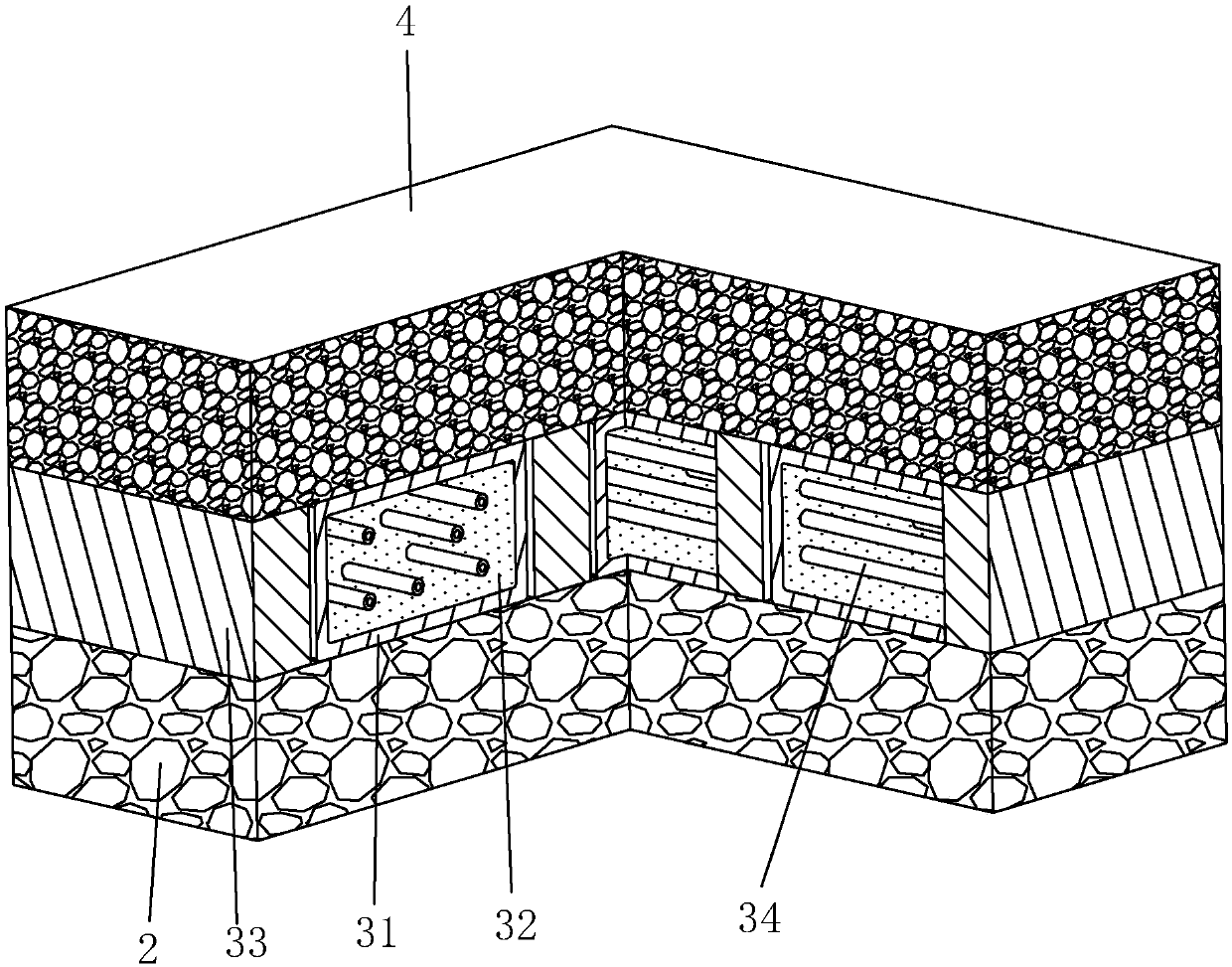

[0076] A foamed asphalt cold recycled pavement structure, such as image 3 As shown, the difference between embodiment 3 and embodiment 1 is that the protective layer 3 also includes a capillary encapsulated with water. The capillaries are interspersed in the calcium oxide layer 32 and covered with calcium oxide. The capillary will be frozen and cracked when the temperature drops to a certain temperature, and the water in the capillary will react with calcium oxide to release heat and increase the temperature of the road surface, so that the protective layer 3 can still protect the road surface even when the air is relatively dry . After the capillary is frozen and cracked, it is possible to puncture the undegraded biodegradable plastic, so that the calcium oxide is exposed in advance to cause an exothermic reaction. The capillary is covered by calcium oxide, and after the capillary freezes and cracks, the moisture contacts the calcium oxide more fully.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com