Flow control method and device, and reaction chamber

A flow control and flow technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as loss and scrapping of the whole furnace, and achieve the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059]In order to enable those skilled in the art to better understand the technical solution of the present invention, the flow control method, device, and reaction chamber provided by the present invention will be described in detail below with reference to the accompanying drawings.

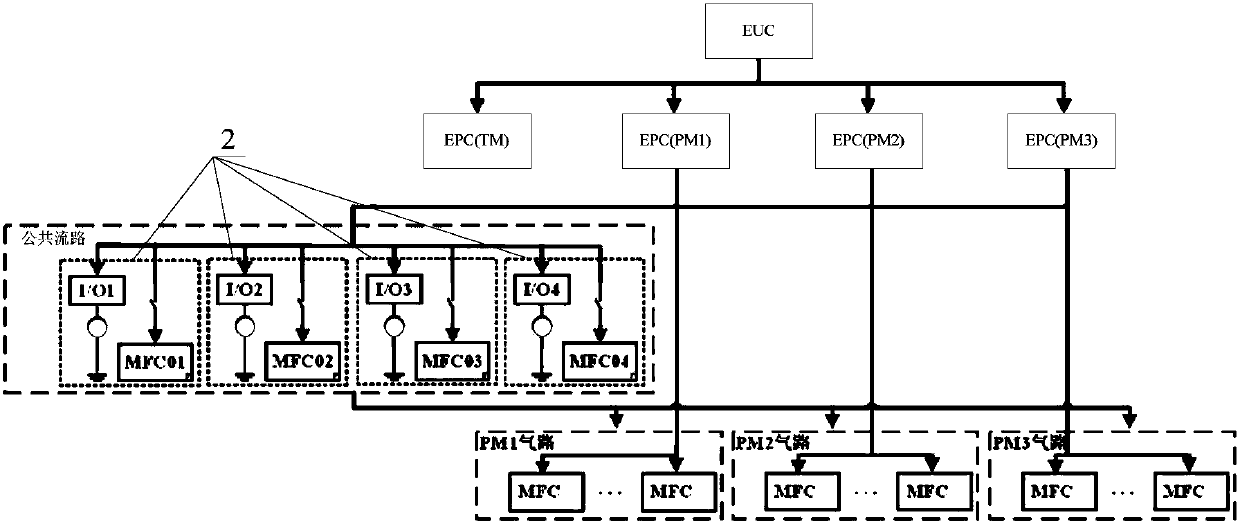

[0060] The flow control method and device provided by the present invention are applied to multi-chamber equipment, for example, multi-chamber CVD equipment, that is, CVD equipment in which a host computer controls multiple process chambers.

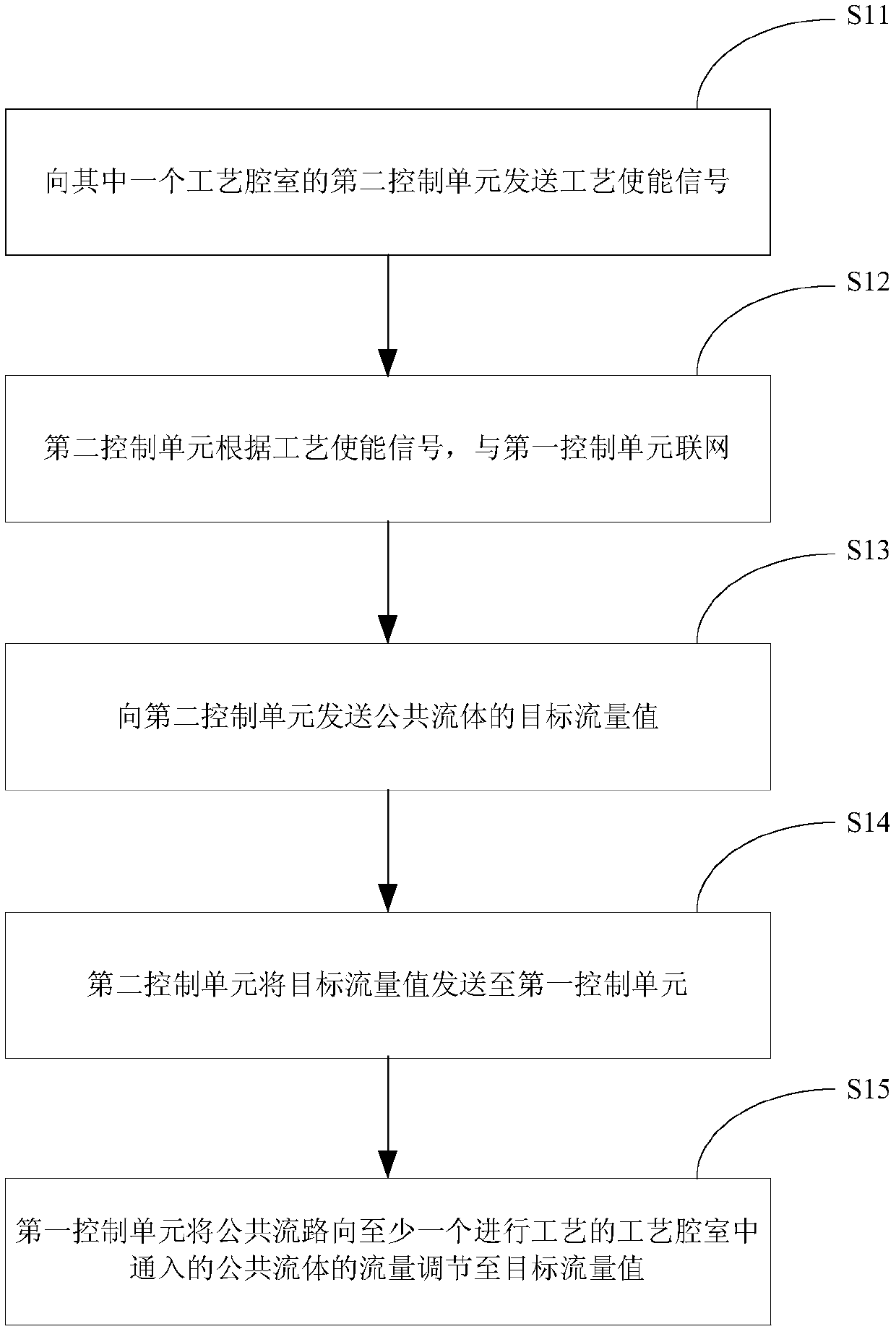

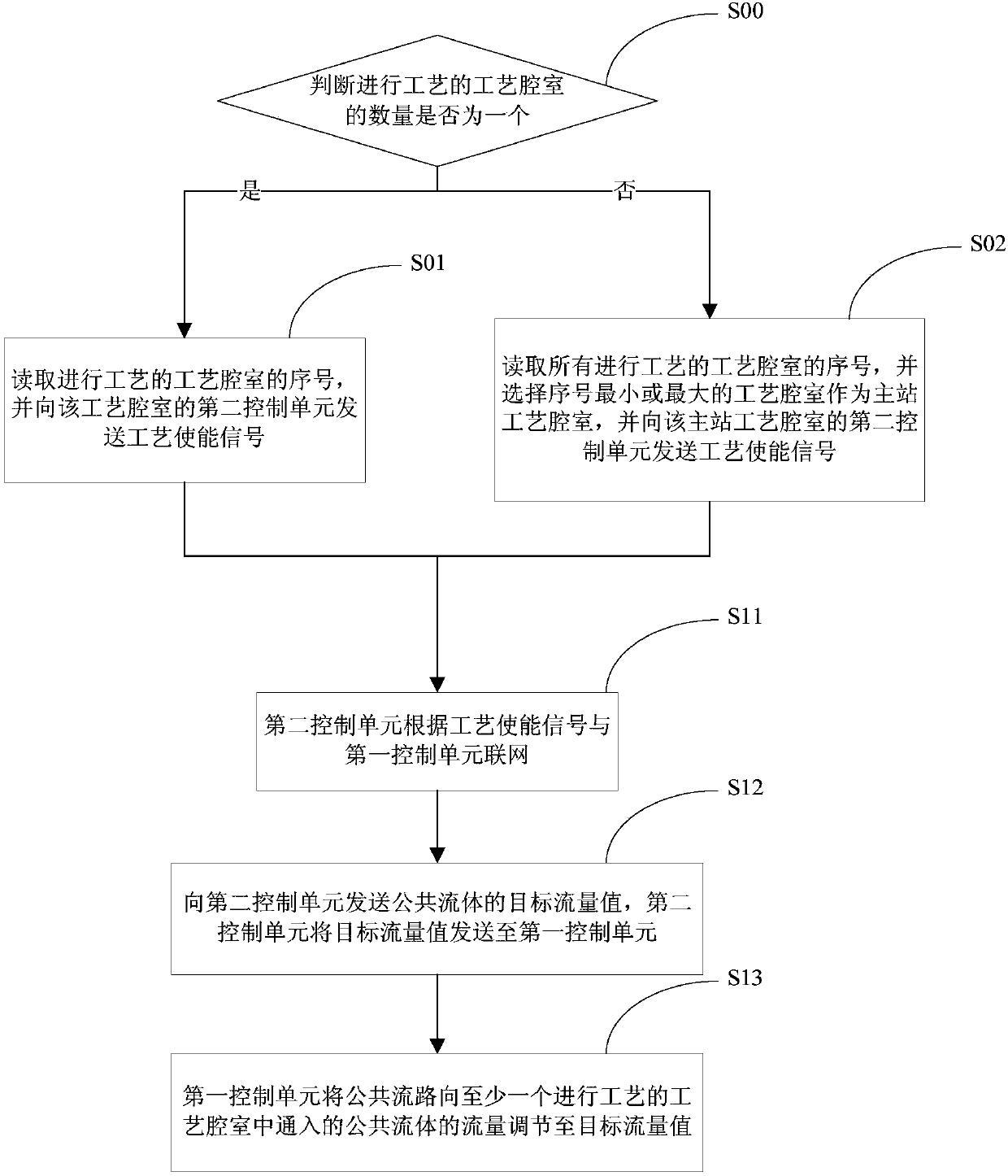

[0061] The flow control method is used to adjust the flow of the common fluid that the common flow path passes into at least one process chamber where the process is performed by controlling the first control unit. The so-called public fluid refers to the gas or liquid required for CVD epitaxy, including N 2 、H 2 , doping gas, etc. Specifically, as figure 1 As shown, the flow control method includes:

[0062] S11, sending a process enabling signal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com