Guide cutting device for PVC extruder

A technology of cutting device and extruder, which is applied in applications, household appliances, and other household appliances, etc. It can solve the problems of uncertain cutting length and unguaranteed cutting quality, achieve uniform length, avoid pipe breakage, and have good guiding and supporting effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

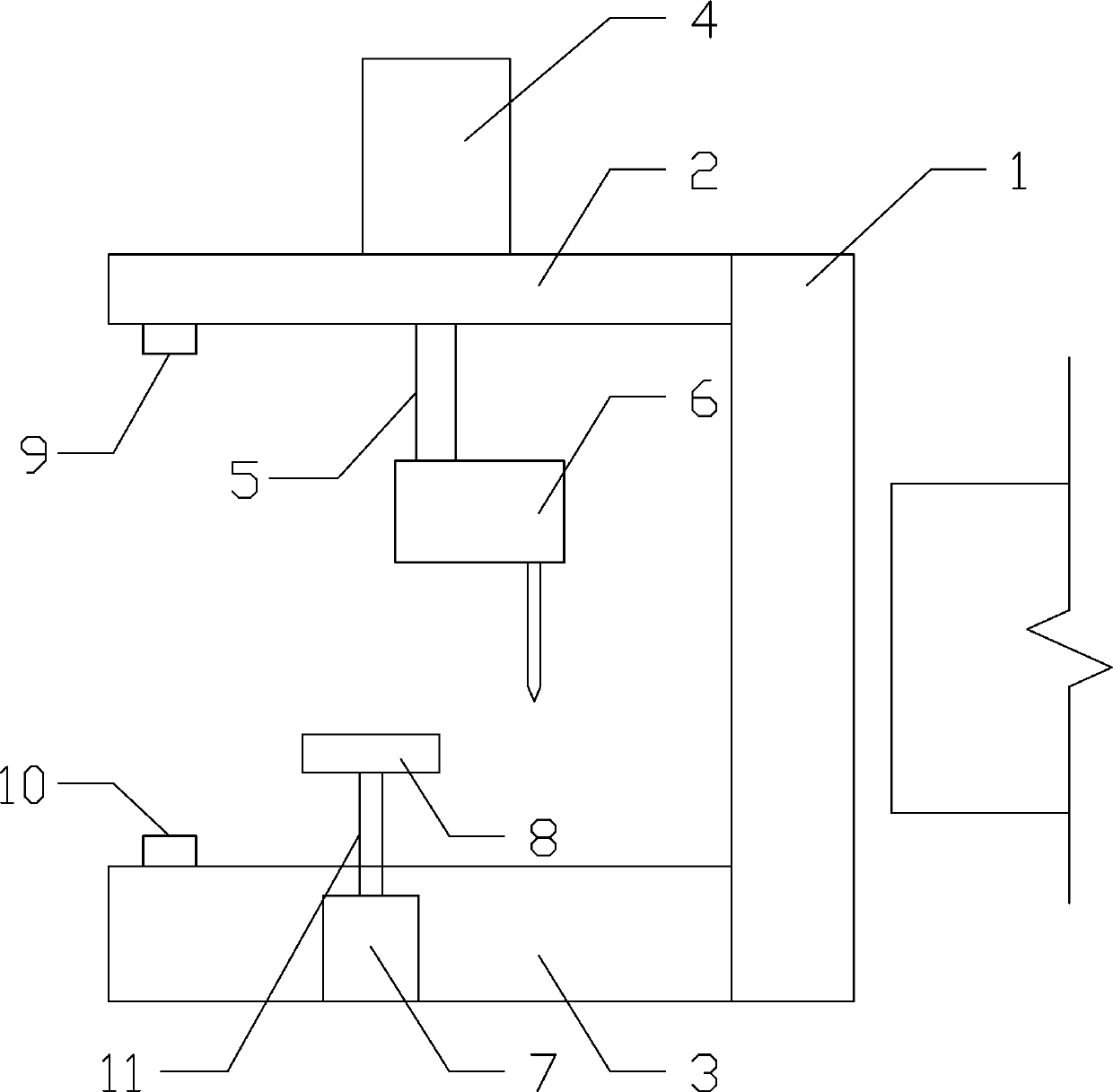

[0023] Such as figure 1 , 3 Among them, a guide cutting device for PVC extruder, including a guide mechanism and a cutting mechanism, the guide mechanism includes a frame 1, a support plate is provided in the frame 1, and the cutting mechanism includes a top plate 2 and a bottom plate 3, and the top plate 2 and the bottom plate 3 A cutting machine 6 is provided between them.

[0024] The top plate 2 is provided with a first hydraulic cylinder 4, the first push rod 5 of the first hydraulic cylinder 4 passes through the top plate 2 and extends between the top plate 2 and the bottom plate 3, and the first push rod 5 is provided with a cutting machine 6.

Embodiment 2

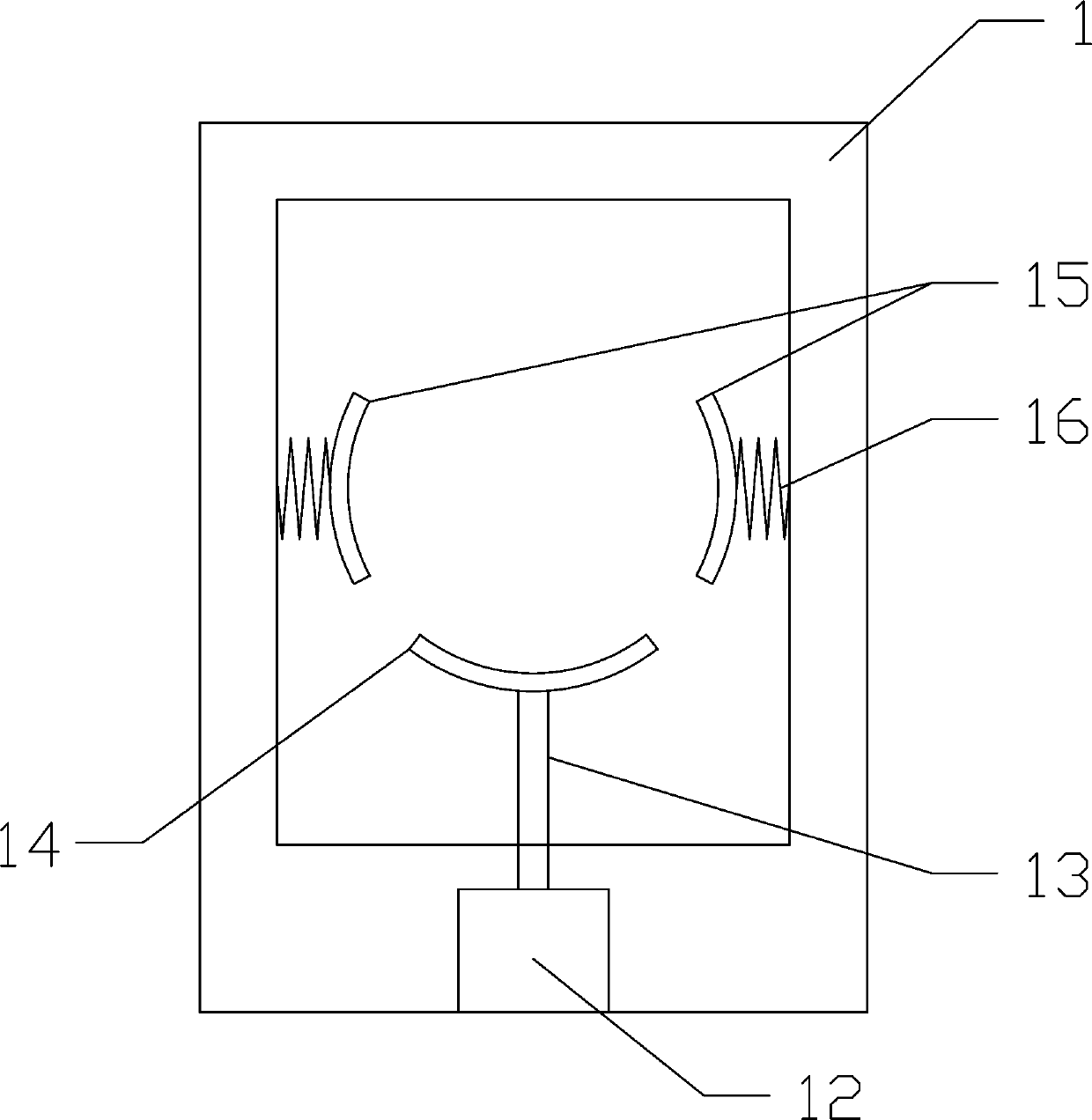

[0026] Such as figure 2 , on the basis of Embodiment 1, the bottom of the frame 1 is provided with a third hydraulic cylinder 12, the third push rod 13 of the third hydraulic cylinder 12 is set vertically upward and the third push rod 13 is provided with a second support Plate 14 , third support plates 15 are provided on both inner sides of the frame 1 , and the third support plates 15 are connected to the inner sides of the frame 1 through springs 16 .

[0027] The bottom plate 3 of the cutting mechanism is provided with a second hydraulic cylinder 7, the second push rod 11 of the second hydraulic cylinder 7 is provided with a first support plate 8, and the first support plate 8 and the second support plate 14 are located at the same on the level.

[0028] The first support plate 8 , the second support plate 14 and the third support plate 15 are all arc-shaped plates, and the concave arc surface is set towards the inside of the guide mechanism and the cutting mechanism.

...

Embodiment 3

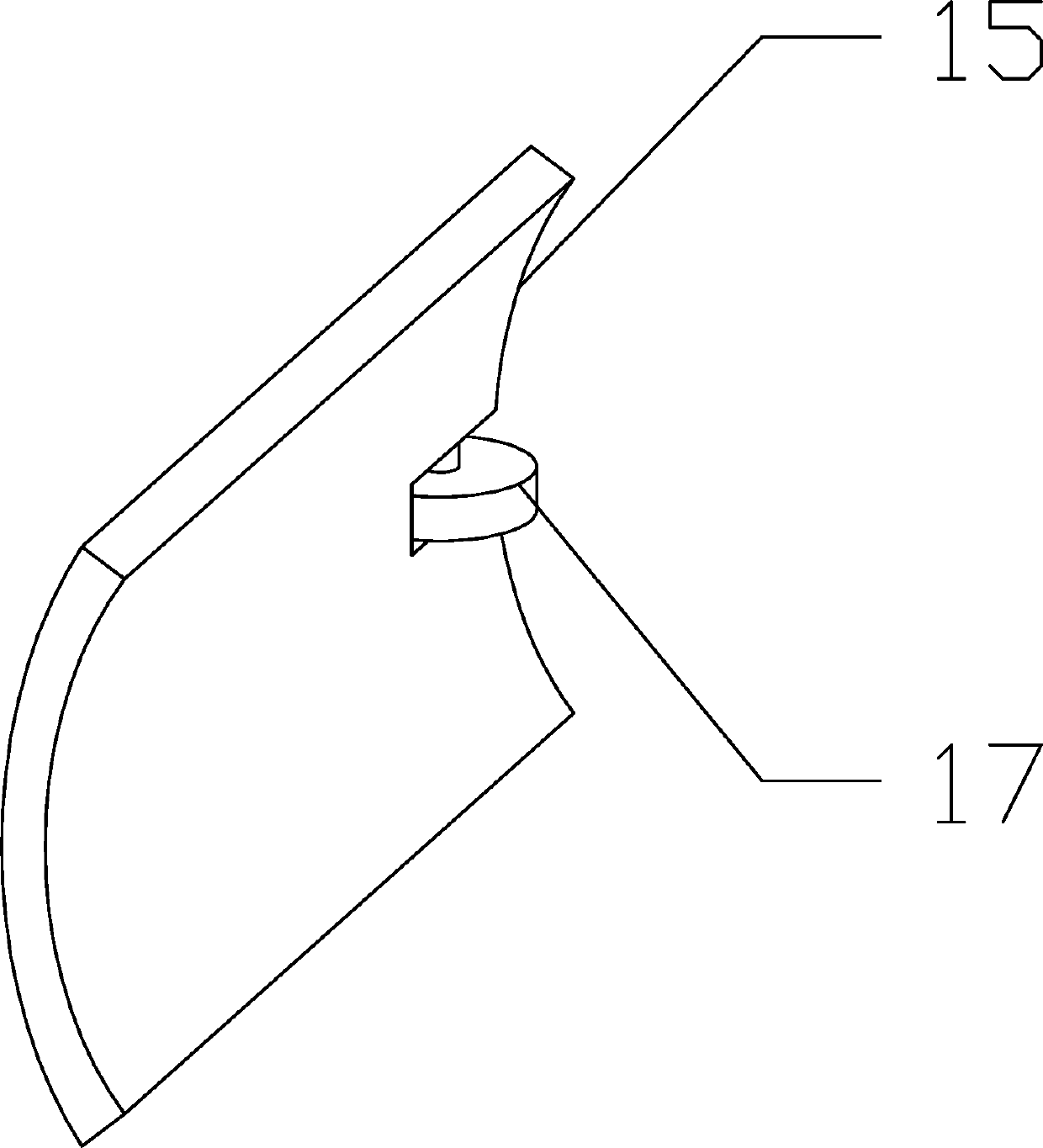

[0033] On the basis of Example 2, the first support plate 8 , the second support plate 14 and the third support plate 15 are all provided with guide wheels 17 near the discharge port of the extruder.

[0034] With the above-mentioned structure, a better supporting effect is achieved for the guidance of the output PVC pipe, which can avoid the pipe breakage caused by the sagging of the output part; the controller controls the precise cutting of the pipe to ensure that the length of the pipe in the same batch is uniform and the product quality is guaranteed. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com