Buried optical cable fault point positioning system combining breakpoint detection and vibration detection

A technology of breakpoint detection and vibration detection, applied in transmission systems, electromagnetic wave transmission systems, electrical components, etc., can solve the problems of wasting time, manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

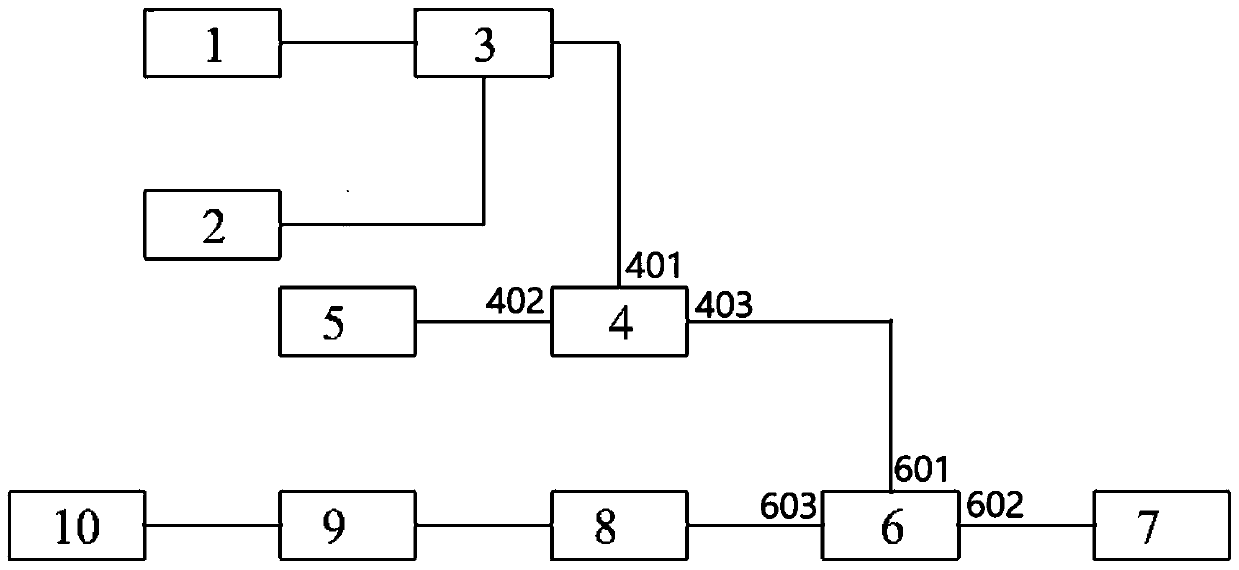

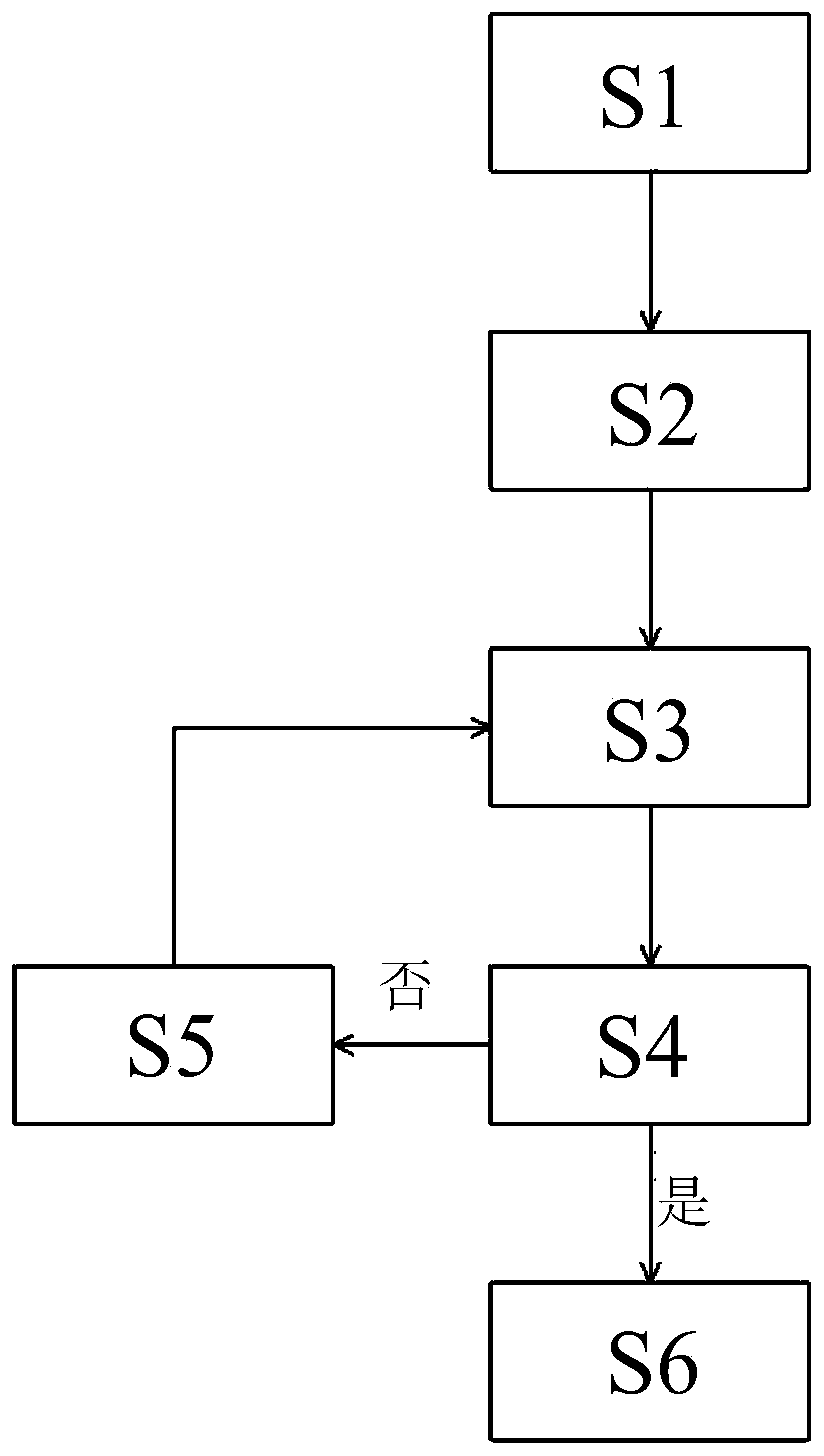

[0044] The specific implementation manners of the present invention will be further introduced below in conjunction with the accompanying drawings.

[0045] The buried optical cable fault point locating system combined with breakpoint detection and vibration detection of the present invention reuses the optical time domain reflection test technology and the phase sensitive optical time domain reflection test technology.

[0046] When the optical switch 3 selects the distributed feedback laser 1 as the light source, the system is in the optical time domain reflection test state.

[0047] After the continuous laser light emitted by the distributed feedback laser 1 passes through the optical switch 3 , the continuous laser light is modulated into pulsed laser light by the acousto-optic modulator 4 , and the pulsed laser light passes through the circulator 6 and enters the optical fiber 7 under test.

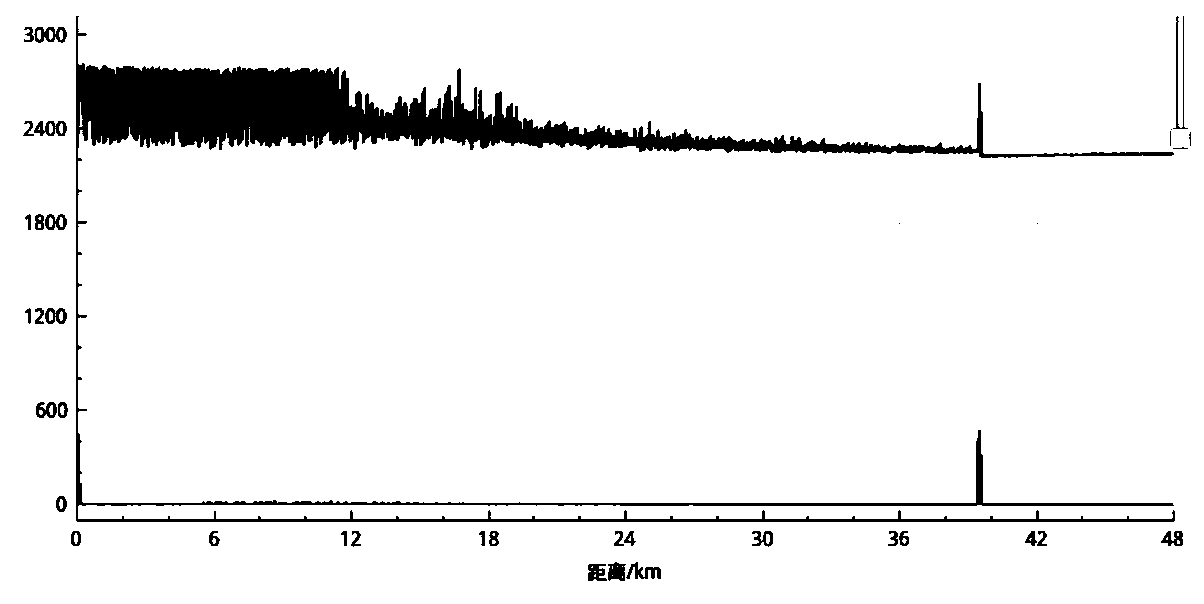

[0048] Rayleigh scattering occurs when the laser beam propagates in the optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com