Method for evaluating non-metallic inclusions in high-strength steel

A technology of non-metallic inclusions and high-strength steel, applied in the direction of applying stable tension/compression to test the strength of materials, etc., can solve the problems of huge evaluation cost, long test time, and complicated processing of fatigue samples, so as to save time and The effect of cost, reliable technical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] An embodiment of the present invention provides a method for evaluating non-metallic inclusions in high-strength steel, comprising the following steps:

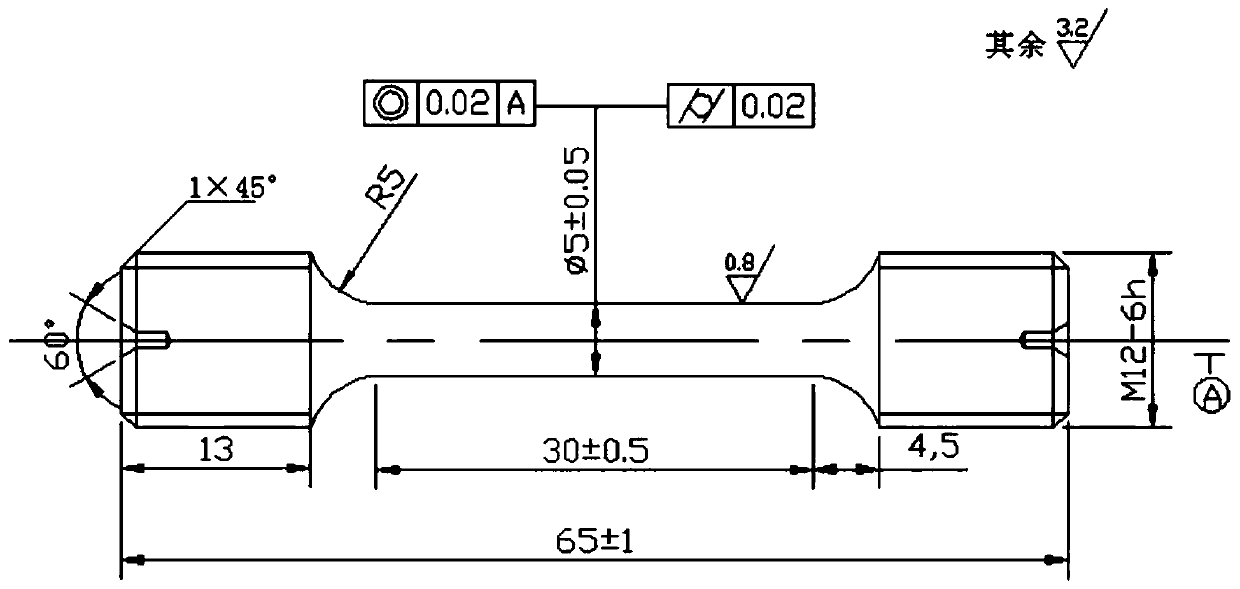

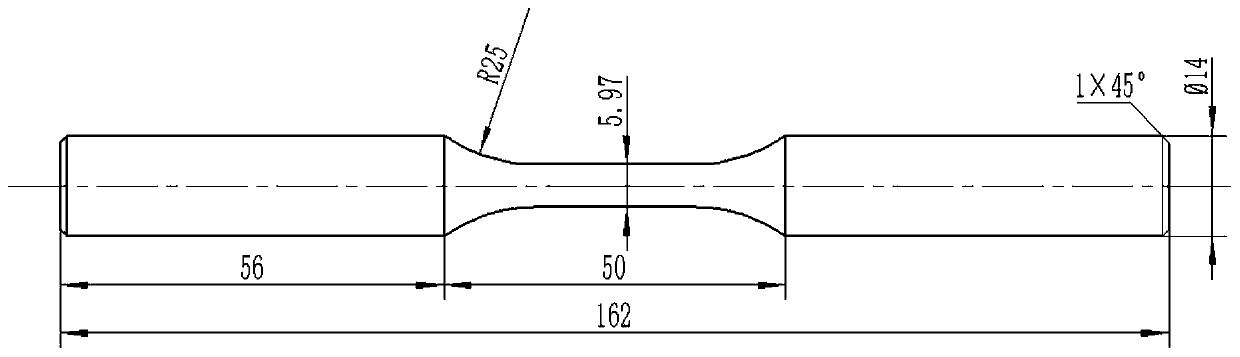

[0041] 1) Process the steel as the evaluation object into tensile specimens after heat treatment;

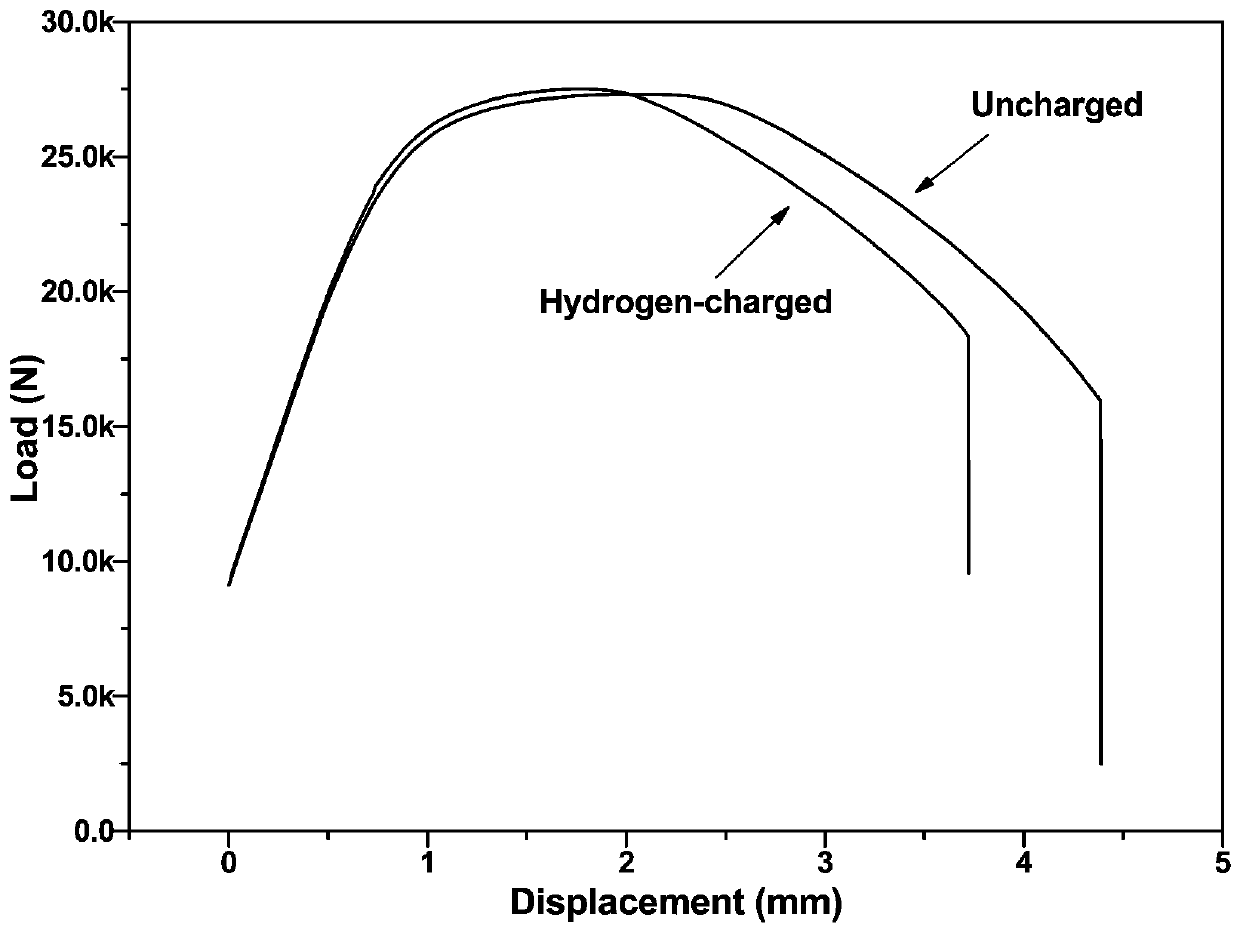

[0042] 2) Charge the tensile sample with hydrogen, and obtain the appropriate hydrogen content by controlling the hydrogen charging process parameters (current density, hydrogen charging time, etc.);

[0043] 3) Carry out a room temperature tensile test to obtain the fracture of the tensile specimen;

[0044] 4) Observe and measure the morphology, size and chemical composition of non-metallic inclusions on the fracture of the tensile specimen under scanning electron microscope and other equipment;

[0045] 5) Statistical analysis was carried out on the characteristic data of non-metallic inclusions on the fracture surfaces of multiple hydrogen-charged tensile specimens, and the extreme value statistical method was used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com