Application of a kind of washing equipment in the pretreatment process of nanometer water-repellent down

A technology of water washing equipment and down, which is applied in the field of down pretreatment, which can solve the problems of down water repellency, low removal rate of grease and impurities, and influence on adsorption, so as to reduce agglomeration, improve functionality, and improve adsorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

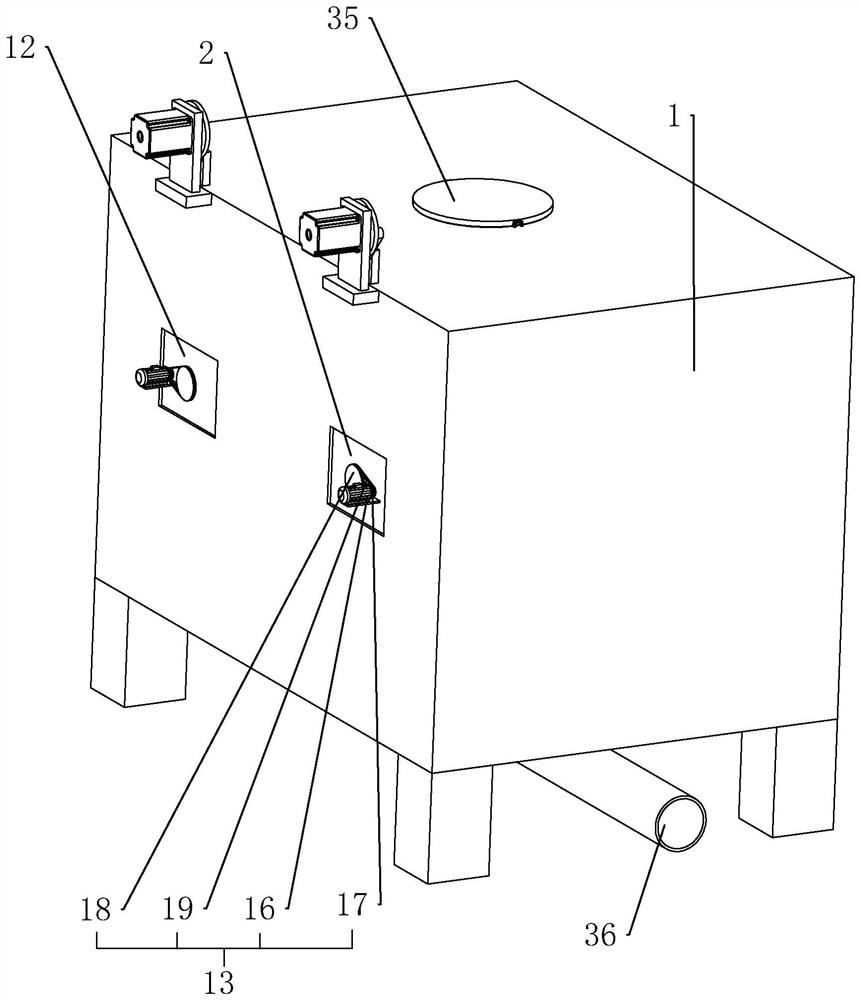

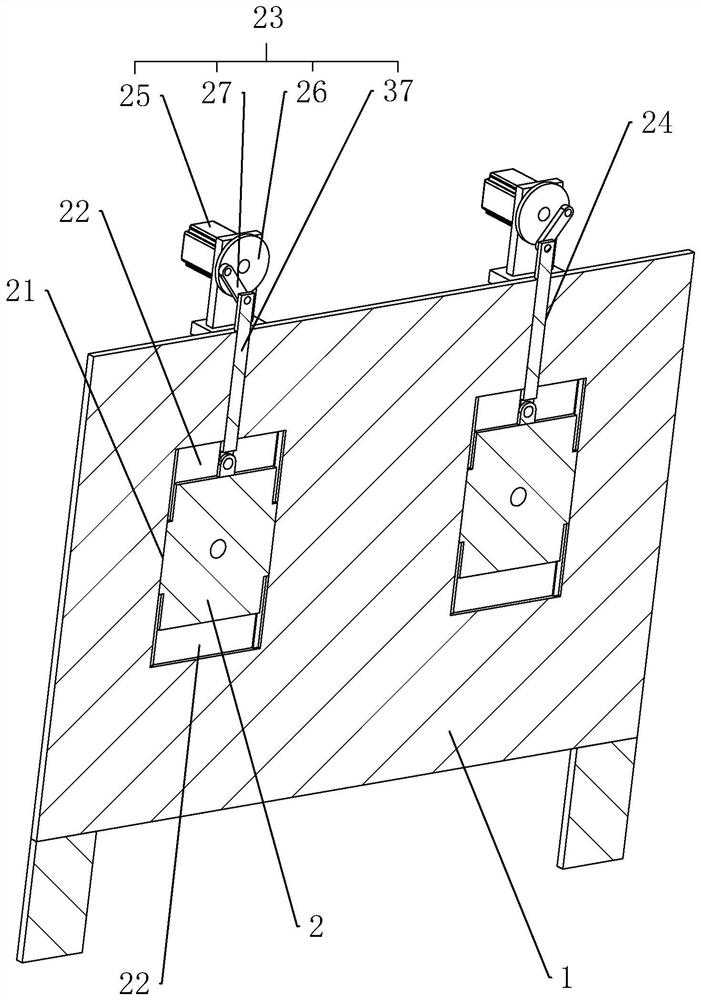

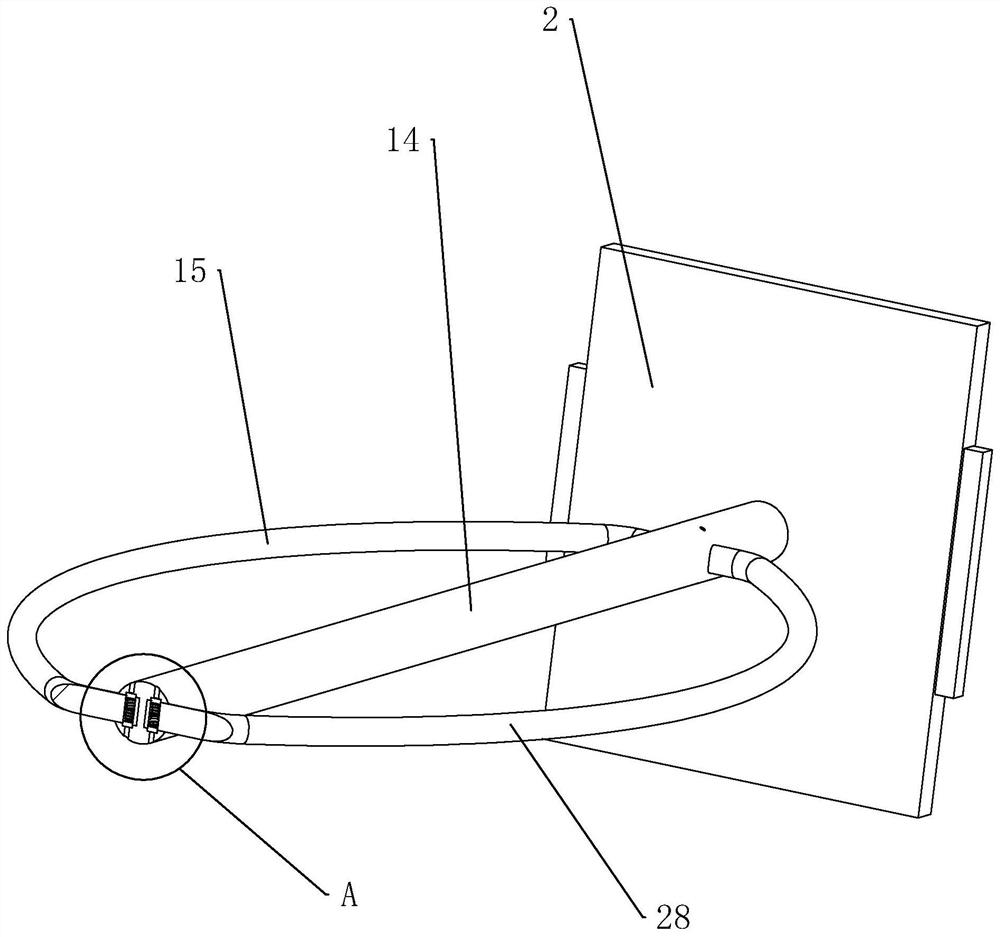

[0063] Application of the pretreatment process for the washing apparatus of the present invention disclosed in the nano water- down in the step of pre-treatment process are as follows:

[0064] S1: Coincide down the down raw material, soak the down raw material;

[0065] S2: Submetled down the down raw material drained;

[0066] S3: water wash preparation, and the aqueous washings were added to the washing apparatus; washing with water temperature controlled at 40-50 deg.] C, stirring speed controlled at 10-15 rev / min. Wash water comprises the following components in parts by weight:

[0067] 30 parts of sodium carbonate;

[0068] Triethanolamine oleate 1 part;

[0069] 0.5 parts ethylenediamine tetraacetic acid;

[0070] 6 parts of ethanol;

[0071] 100 parts of water;

[0072] 60 parts emulsifier;

[0073] Penetrant 20 parts.

[0074] Weight percent of an emulsifier component comprising:

[0075] Coconut oil fatty acid diethanolamide 30%;

[0076] Twain -2010%;

[0077] Coconu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com