High-efficiency cleansing paste and preparation method thereof

A cleaning cream and high-efficiency technology, applied in chemical instruments and methods, preparation of detergent mixture compositions, detergent compositions, etc., can solve problems such as skin damage of cleansers, and achieve easy scrubbing, mild skin, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In a second aspect, the present invention provides a method for preparing the high-efficiency cleaning paste as described in the first aspect, comprising the steps of:

[0040] (1) Weigh the raw materials in proportion, add sodium alginate, preservative and antibacterial agent to 10-30% of the formula amount in pure water, soak and dissolve to obtain mixture A; anionic surfactant, nonionic surfactant Agent, amphoteric surfactant are mixed to obtain mixed surfactant;

[0041] (2) Take 10-20% of the pure water of the formula amount, add the mixed surfactant obtained in step (1) of 1-5% of the total weight, dissolve into a dilute surfactant aqueous solution, and then slowly add the abrasive while stirring , making it evenly dispersed in the surfactant aqueous solution to obtain the mixture B;

[0042] (3) Add the mixture A obtained in step (1) and the pure water of the remaining formula amount to the stirring equipment, and stir at a high speed until it is evenly disperse...

Embodiment 1~7

[0046] A preparation method of high-efficiency cleaning paste, comprising the steps of:

[0047] (1) take raw materials by weight ratio as described in Table 1;

[0048] (2) Sodium alginate and ethylparaben are added into 20% pure water of formula quantity and soaked at normal temperature to obtain mixture A; triethanolamine cocoate, fatty alcohol polyoxyethylene ether sulfate, alkyl Glycosides are mixed to obtain mixed surfactants;

[0049] (3) Take 15% pure water of the formula amount, add the weighed alkyl glucoside into it and stir until it is completely dissolved, and disperse the shell powder in it to a homogeneous phase while stirring, to obtain the mixture B;

[0050] (4) Add the mixture A obtained in step (2) to the stirring equipment, stir at a high speed until it is evenly dispersed, then add the mixture B obtained in step (2) and the remaining mixture obtained in step (1) to the stirring equipment Surfactant, glycerin and chelating agent are stirred again and gro...

Embodiment 1

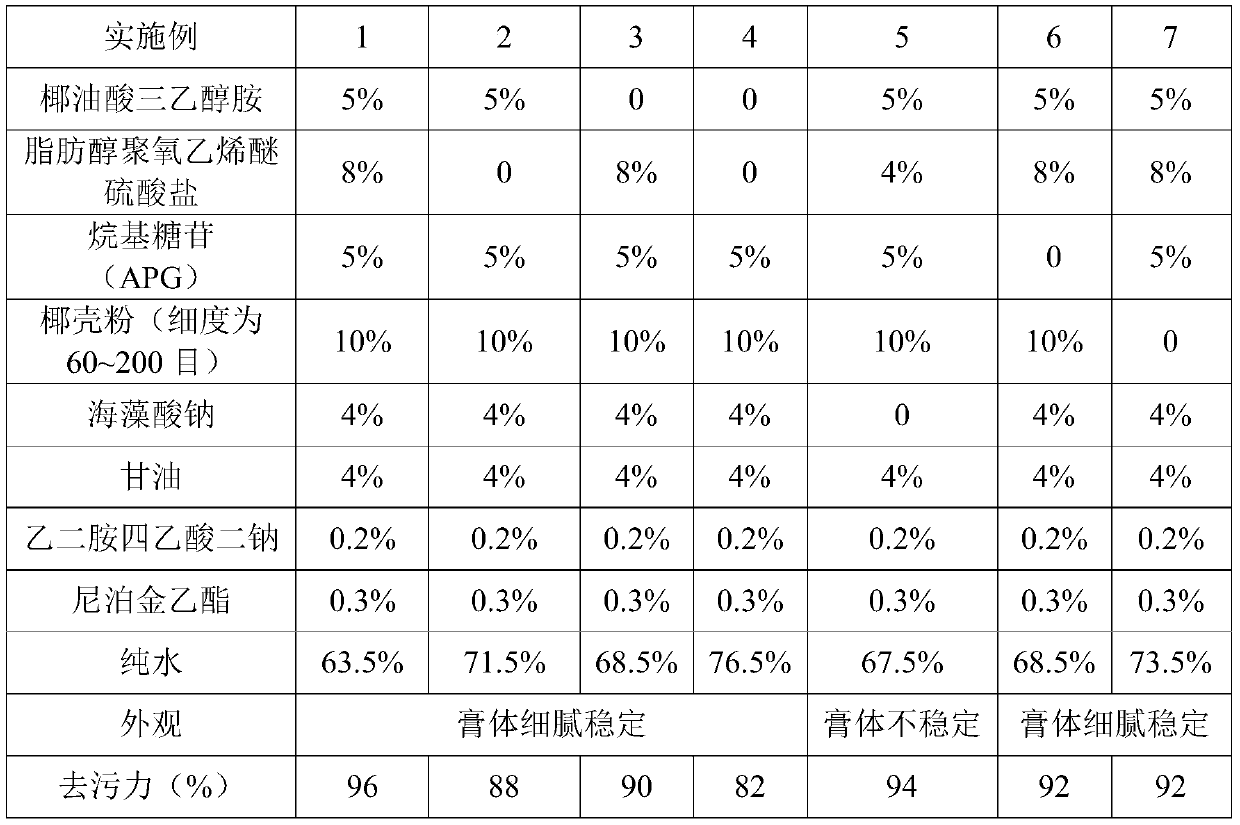

[0052] The formula ratio of the cleaning paste in Example 1 is obtained through the comparative experiments of Examples 1 to 7. See Table 1 for the specific experimental proportions and performance data.

[0053] For the raw materials used in the table, except for the surfactant, the addition amount of other raw materials is determined by cross-experimentation to determine the amount of each type of filler used in the formula to ensure the paste storage stability of the cleaning paste.

[0054] The raw material consumption (by weight percentage) and performance test result of table 1 embodiment 1~7 high-efficiency cleaning paste

[0055]

[0056] The detergency test method in Table 1 is the detergency test method in GBT35833-2018 kitchen oil cleaning agent.

[0057] It can be seen from Table 1 that the synergistic effect of several surfactants makes the decontamination effect better. At the same time, the addition of additives and abrasives also improves the decontamination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com