Method for gasification reduction of pulverized coal and separation and recycling of liquid

A liquid separation and pulverized coal technology, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of small processing capacity and difficult industrial application, and achieve the effect of increasing production and improving reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

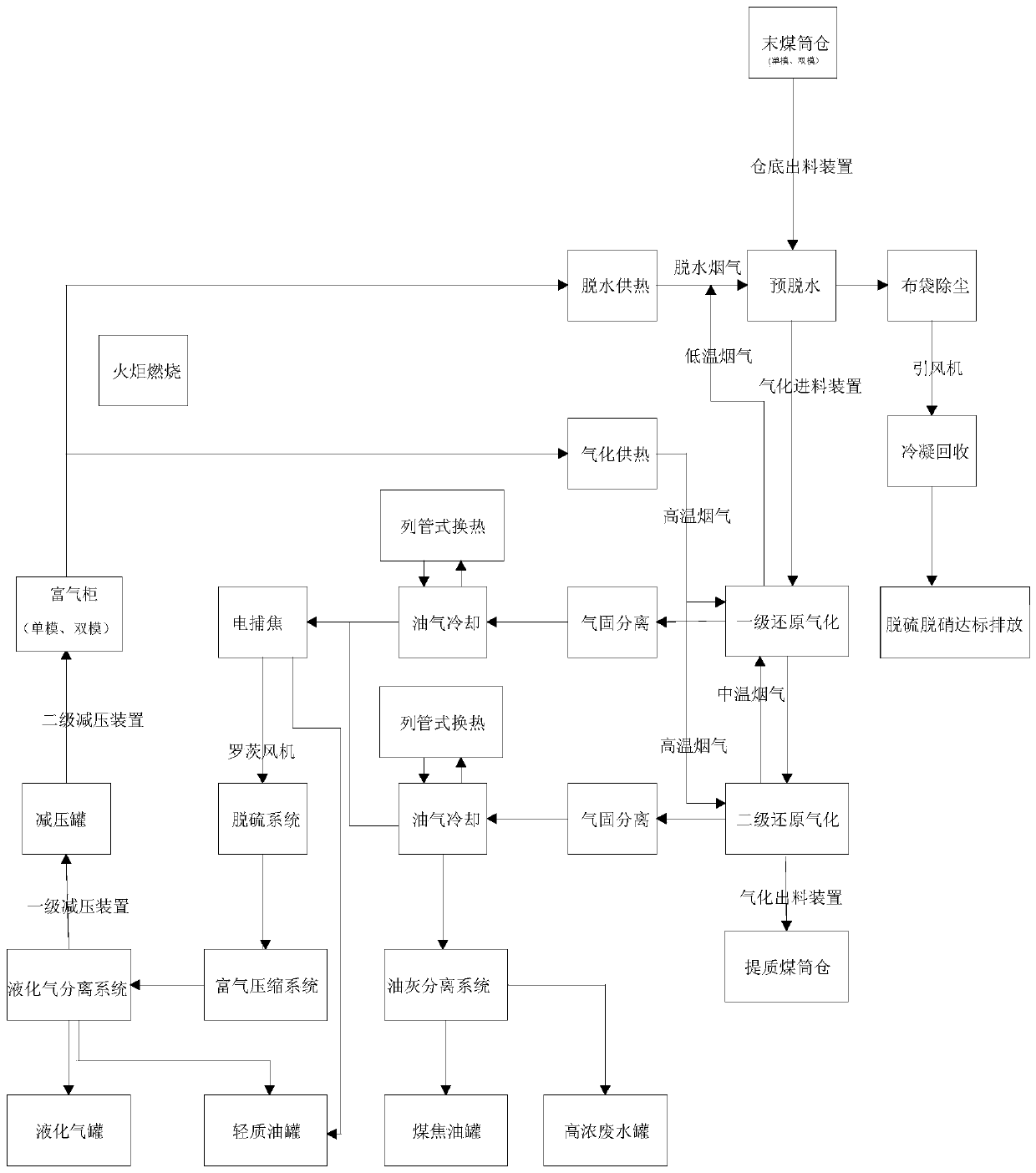

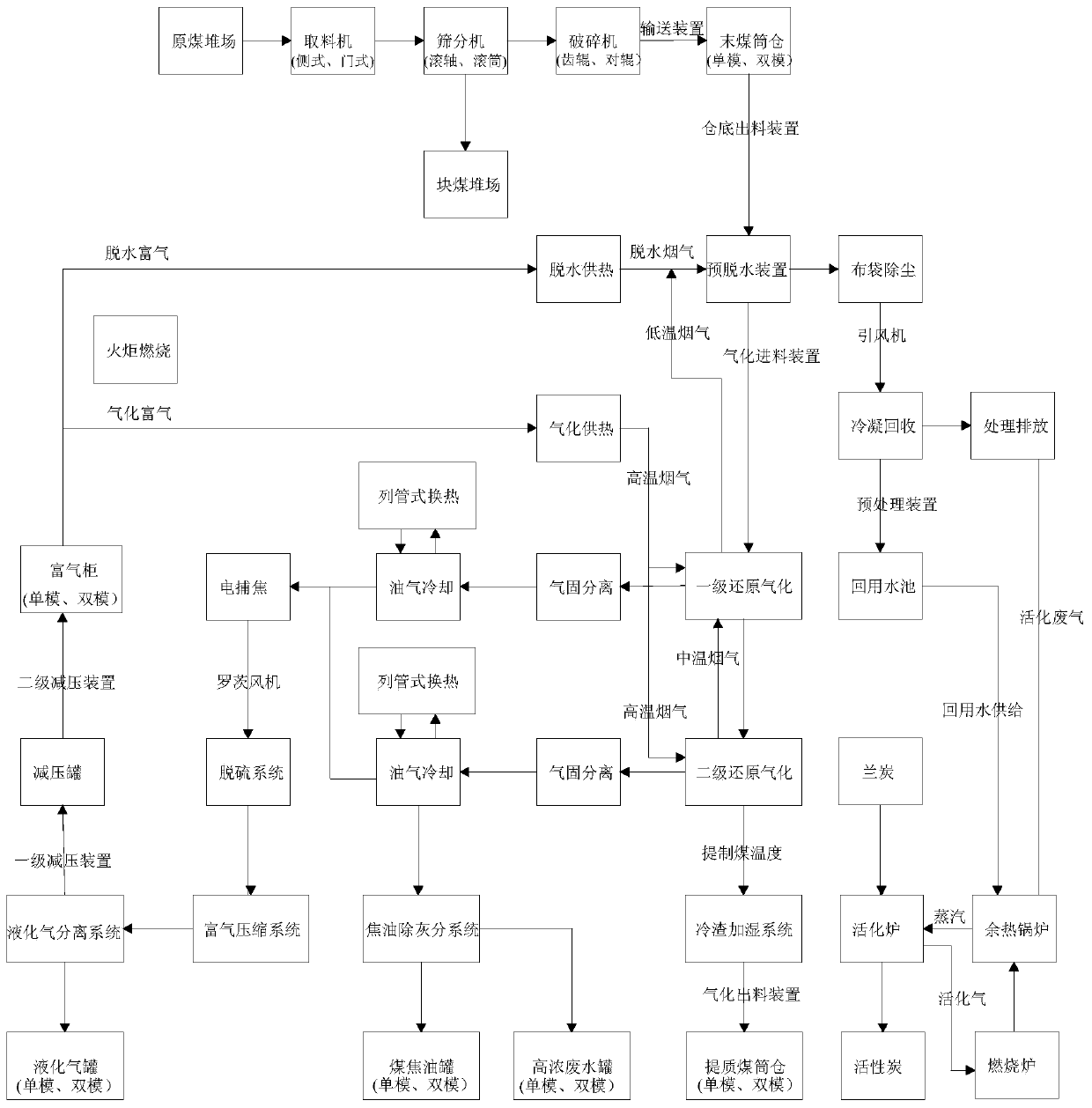

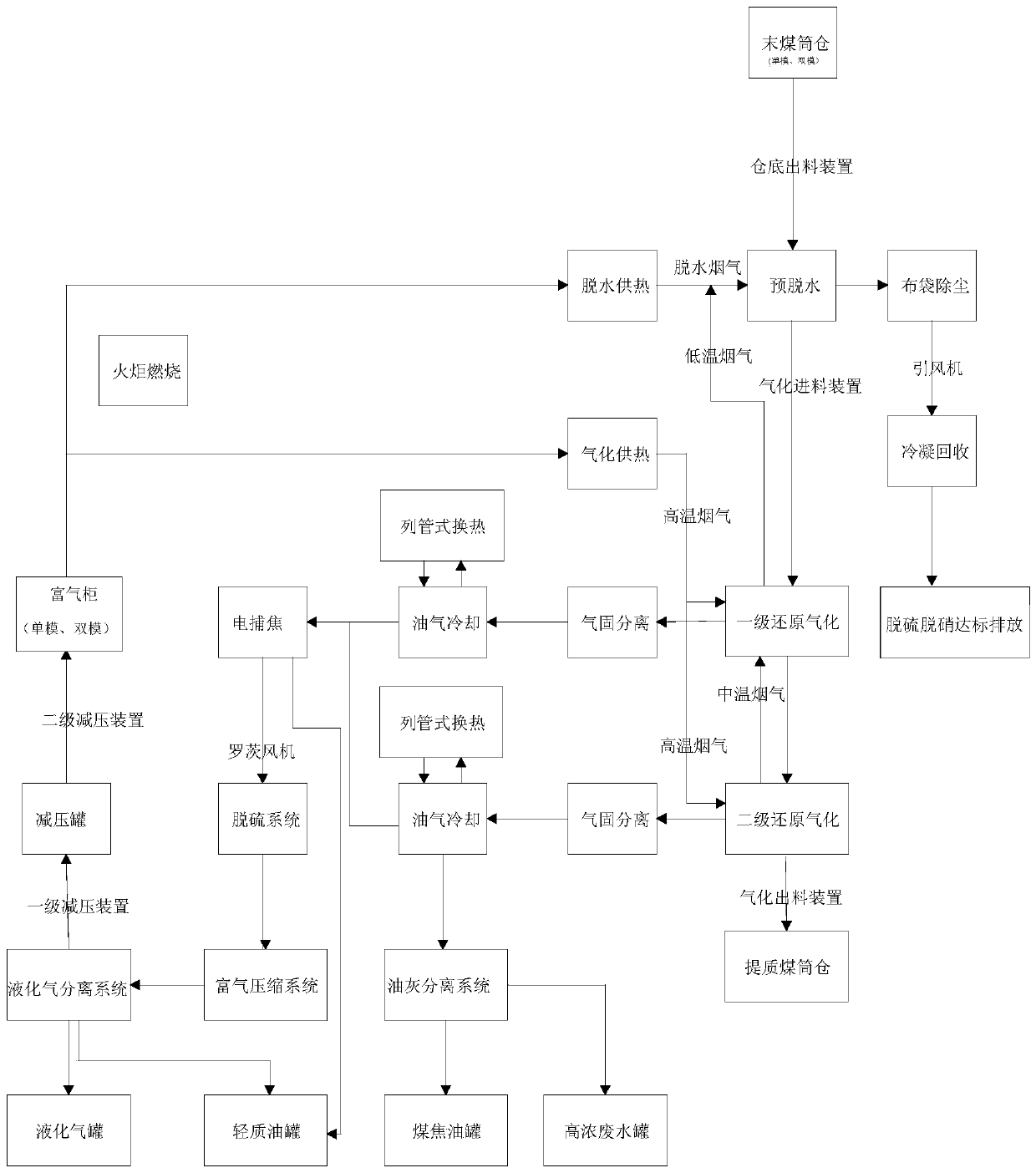

[0121] Such as figure 1 , figure 2 As shown, a method for pulverized coal gasification reduction and liquid separation and recovery includes the following steps:

[0122] (1) The pulverized coal in the powder coal silo enters the pre-dehydration device for drying through the discharge device at the bottom of the silo, and the dried pulverized coal enters the primary gasification reduction device through the gasification feeding device, and the reacted solid material is then passed through The airtight high-temperature-resistant conveying device enters the secondary gasification and reduction device.

[0123] The coal stored in the powder coal silo is easy to raise dust, so a bottom dust collector is installed on the top to prevent dust from escaping. The storage capacity of the powder coal silo is 1500T / day, and the material is conveyed through the buried scraper and screw at the bottom of the silo, etc. The combined discharge device discharges the material, adopts a single...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com