Highlight anti-warping nylon PA6/PC (Polyamide 6/Polycarbonate) alloy

An anti-warping and nylon technology, applied in the field of high-gloss anti-warping nylon PA6/PC alloy, can solve the problems of non-wear-resistant surface, poor product surface, uneven product, etc., and maintain heat aging resistance and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

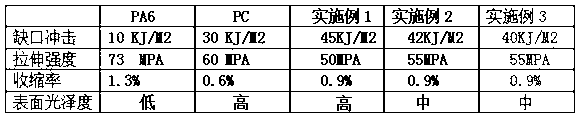

Embodiment 1

[0032] A high-gloss anti-warpage nylon PA6 / PC alloy, comprising the following components in parts by weight:

[0033] Polyamide resin (PA6) 50 parts

[0034] Polycarbonate (PC) 50 parts

[0035] Compatibilizer 15 parts

[0036] Antioxidant 1098 0.02 parts

[0037] Antioxidant 626 0.02 parts

[0038] Lubricant 0.5 part.

[0039] Specifically, the viscosity of the polyamide resin (PA6) is 2.8. Among them, the polyamide resin (PA6) is Xinhui Meida M2800.

[0040] Specifically, the viscosity of the polycarbonate (PC) is 2.8. Among them, polycarbonate (PC) is Bayer BAYER2805 of Germany.

[0041] Specifically, the compatibilizer is POE-g-MAH, PE-g-ST, PP-g-ST, ABS-g-MAH, PP-g-MAH, EVA, SEBS, SEBS-g-MAH, PE -Two or more of g-MAH. In addition, a compound compatible toughening agent can be added to reduce stress and improve dispersion. The compound compatible toughening agent is French Arkema 4700 / EEA ethylene-ethyl acrylate copolymer.

[0042] Specifically, the lubricant is ...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that a high-gloss anti-warpage nylon PA6 / PC alloy includes the following components in parts by weight:

[0052] Polyamide resin (PA6) 60 parts

[0053] Polycarbonate (PC) 40 parts

[0054] 12 parts of compatibilizer

[0055] Antioxidant 1098 0.02 parts

[0056] Antioxidant 626 0.02 parts

[0057] Lubricant 0.5 parts.

[0058] The present invention also discloses a method for preparing the PA6 / PC alloy, comprising the following steps:

[0059] (1) Preparation of raw materials: In parts by weight, it includes 60 parts of polyamide resin (PA6), 40 parts of polycarbonate (PC), 12 parts of compatibilizer, 0.02 parts of antioxidant 1098, 0.02 parts of antioxidant 626, 0.5 parts of lubricant;

[0060] (2) Dry and pretreat the raw materials weighed according to the above proportions, add and blend in sequence, mix in a high-speed mixer for a total of 10 minutes, and then send them to the twin-screw extruder for m...

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 is that a high-gloss anti-warpage nylon PA6 / PC alloy includes the following components in parts by weight:

[0064] Polyamide resin (PA6) 70 parts

[0065] Polycarbonate (PC) 30 parts

[0066] Compatibilizer 10 parts

[0067] Antioxidant 1098 0.02 parts

[0068] Antioxidant 626 0.02 parts

[0069] Lubricant 0.5 parts.

[0070] The present invention also discloses a method for preparing the PA6 / PC alloy, comprising the following steps:

[0071] (1) Preparation of raw materials: In parts by weight, it includes 70 parts of polyamide resin (PA6), 30 parts of polycarbonate (PC), 10 parts of compatibilizer, 0.02 parts of antioxidant 1098, 0.02 parts of antioxidant 626, 0.5 parts of lubricant;

[0072] (2) Dry and pretreat the raw materials weighed according to the above proportions, add and blend in sequence, mix in a high-speed mixer for a total of 10 minutes, and then send them to the twin-screw extruder for meltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com