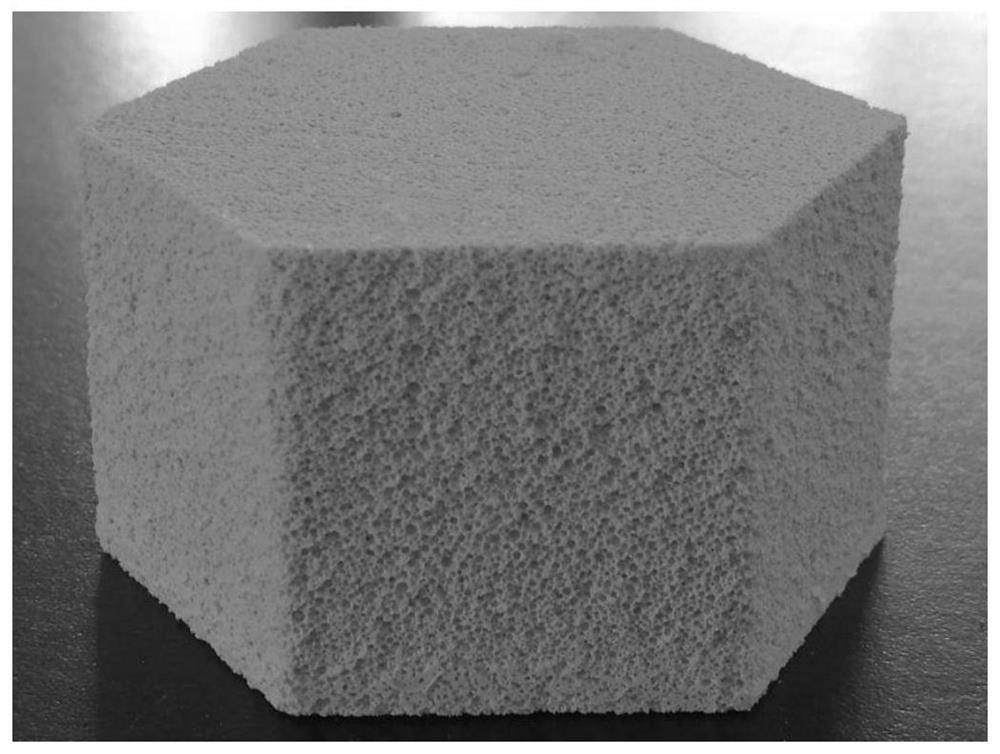

A kind of high temperature resistant foamed ceramics prepared by FCC waste catalyst and preparation method thereof

A foamed ceramic and waste catalyst technology, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problem of not being able to fundamentally solve the problem of waste catalyst disposal, reducing the output of FCC waste catalyst, and the limited recovery and reuse effect. Achieve the effect of improving mechanical stability, low ceramic density, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

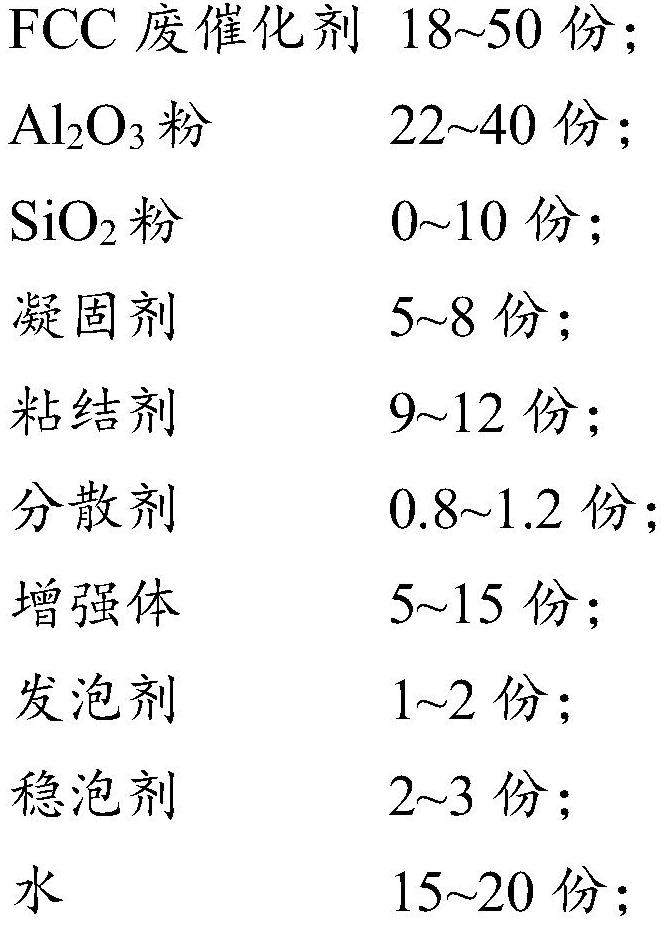

[0048] The present invention also provides a method for preparing the high-temperature-resistant foamed ceramic described in the above-mentioned technical solution, comprising the following steps:

[0049] (1) FCC waste catalyst, Al 2 o 3 Powder, SiO 2 mixing the powder and coagulant to obtain a first mixture; mixing the binder, dispersant and water to obtain a second mixture; mixing the first mixture with the second mixture to obtain a first ceramic slurry;

[0050] (2) Adding a foaming agent, a foam stabilizer and a pH regulator to the first ceramic slurry in sequence to obtain a second ceramic slurry;

[0051] (3) adding a reinforcing body to the second ceramic slurry, and then foaming to obtain a foamed ceramic slurry;

[0052] (4) performing vibration treatment after injecting the foamed ceramic slurry until no more air bubbles with a diameter of 10 mm or more escape in the ceramic slurry to obtain an injection molded ceramic slurry;

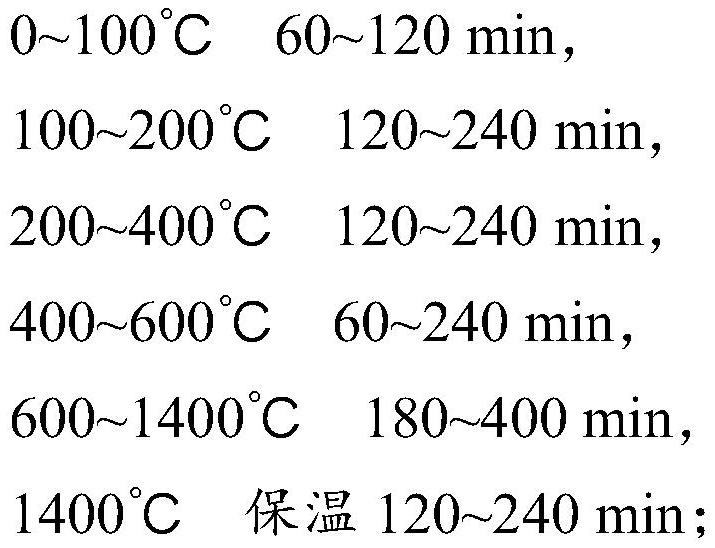

[0053] (5) Demoulding the inject...

Embodiment 1

[0065] In parts by mass, the preparation raw materials used are: 30 parts of FCC waste catalyst, Al 2 o 3 Powder 25 parts, SiO 2 5 parts of powder, 7 parts of coagulant, 10 parts of binder, 1 part of dispersant, 1 part of foaming agent, 2 parts of foam stabilizer, 10 parts of reinforcement, 20 parts of deionized water and to adjust the waste containing FCC Catalyst, Al 2 o 3 Powder, SiO 2 Powder, coagulant, binder, dispersant, foaming agent, foam stabilizer and water mixed system pH value to 8-11 based on the pH value regulator.

[0066] The preparation method is as follows: 3kg FCC waste catalyst, 2.5kgAl 2 o 3 Powder, 0.5kg SiO 2 Flour and 0.7kg starch are stirred and mixed to obtain the first mixture, then add the second mixture composed of 2kg deionized water, 1kg silica sol and 0.1kg ammonium polyacrylate to the first mixture, and use an electric mixer at 900r / min Stir rapidly for 30 minutes at a certain stirring speed to form the first ceramic slurry with stable ...

Embodiment 2

[0072] In terms of parts by mass, the preparation raw materials used are: 36 parts of FCC spent catalyst, Al 2 o 3 24 parts powder, SiO 2 10 parts of powder, 6 parts of coagulant, 10 parts of binder, 1 part of dispersant, 2 parts of foaming agent, 3 parts of foam stabilizer, 10 parts of reinforcement, 20 parts of deionized water and to adjust the waste containing FCC Catalyst, Al 2 o 3 Powder, SiO 2 Powder, coagulant, binder, dispersant, foaming agent, foam stabilizer and water mixed system pH value to 8-11 based on the pH value regulator.

[0073] The preparation method is as follows: 180g FCC waste catalyst, 120g Al 2 o 3 powder, 50g SiO 2 Powder and 30g starch are stirred and mixed to obtain the first mixture, and then the second mixture composed of 100g deionized water, 50g silica sol and 5g ammonium polyacrylate is added to the first mixture, and stirred at 2000r / min by an electric mixer Stir rapidly at a high speed for 10 minutes to form the first ceramic slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com