Preparation and application of activated (Cu-Fe-Ce)/Al2O3 nanoparticle electrode

A cu-fe-ce, nano-particle technology, applied in the direction of oxidized water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problems of catalytic activity failure, high power consumption, high manufacturing cost, etc. problem, to achieve the effect of improving catalytic oxidation activity, high treatment efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

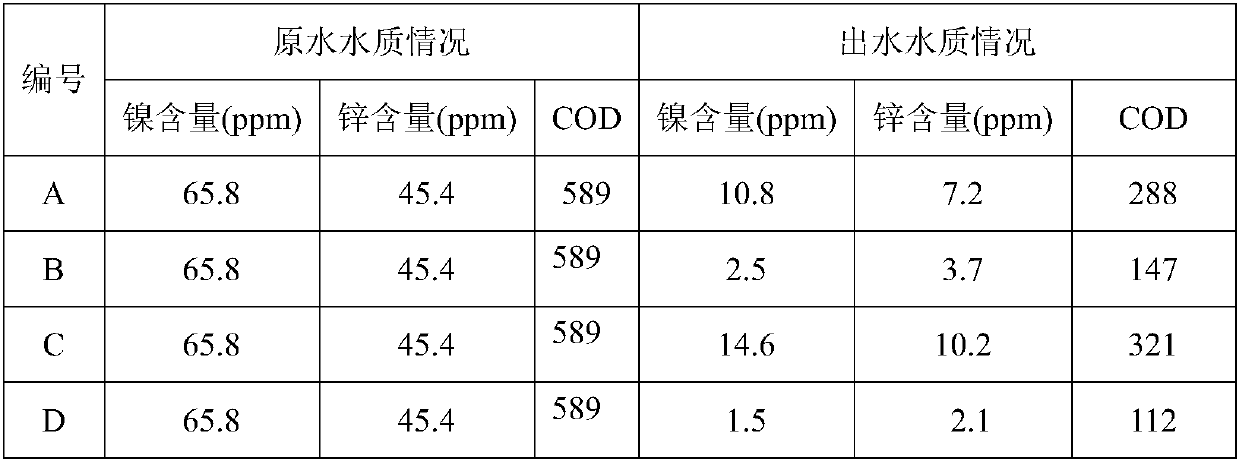

Examples

Embodiment 1

[0035] (1) Copper nitrate, ferric nitrate and cerium nitrate are added in the beaker that fills 100mL deionized water according to the ratio of 2: 2: 1, magnetic stirring;

[0036] (2) Add sodium citrate monohydrate to the homogeneous solution formed in step (1), until the mol ratio of sodium citrate / (Cu+Fe+Ce) is 1: 1, continue stirring until completely dissolved;

[0037] (3) The homogeneous solution that step (2) forms is transferred to the 2 o 3 Erlenmeyer flask, active Al 2 o 3 Particle size is 3~5mm, active Al 2 o 3 The mass is about 100g;

[0038](4) Transfer it to a constant temperature oscillator and react for 10 hours;

[0039] (5) The solution in step (4) is filtered, washed and dried at 80°C to obtain (Cu-Fe-Ce) / Al 2 o 3 Precursors for nanoparticle electrodes;

[0040] (6) Transfer the precursor obtained in step (5) to a muffle furnace, and then carry out a temperature program at a rate of 10 °C / min, from room temperature to 200 °C, and keep it for 60 min;...

Embodiment 2

[0043] (1) Copper nitrate, ferric nitrate and cerium nitrate are added in the beaker that fills 100mL deionized water according to the ratio of 4: 4: 1, magnetic stirring;

[0044] (2) Add sodium citrate monohydrate to the homogeneous solution formed in step (1), until the mol ratio of sodium citrate / (Cu+Fe+Ce) is 1: 1, continue stirring until completely dissolved;

[0045] (3) The homogeneous solution that step (2) forms is transferred to the 2 o 3 Erlenmeyer flask, active Al 2 o 3 Particle size is 3~5mm, active Al 2 o 3 The mass is about 100g;

[0046] (4) Transfer it to a constant temperature oscillator and react for 10 hours;

[0047] (5) The solution in step (4) is filtered, washed and dried at 80°C to obtain (Cu-Fe-Ce) / Al 2 o 3 Precursors for nanoparticle electrodes;

[0048] (6) Transfer the precursor obtained in step (5) to a muffle furnace, and then carry out a temperature program at a rate of 10 °C / min, from room temperature to 200 °C, and keep it for 60 min...

Embodiment 3

[0051] (1) Cupric chloride, ferric chloride and cerium nitrate are joined in the beaker that fills 100mL deionized water according to the ratio of 2: 2: 1, magnetically stirred;

[0052] (2) Add sodium citrate monohydrate to the homogeneous solution formed in step (1), until the mol ratio of sodium citrate / (Cu+Fe+Ce) is 1: 1, continue stirring until completely dissolved;

[0053] (3) The homogeneous solution that step (2) forms is transferred to the 2 o 3 Erlenmeyer flask, active Al 2 o 3 Particle size is 3~5mm, active Al 2 o 3 The mass is about 100g;

[0054] (4) Transfer it to a constant temperature oscillator and react for 10 hours;

[0055] (5) The solution in step (4) is filtered, washed and dried at 80°C to obtain (Cu-Fe-Ce) / Al 2 o 3 Precursors for nanoparticle electrodes;

[0056] (6) Transfer the precursor obtained in step (5) to a muffle furnace, and then carry out a temperature program at a rate of 10 °C / min, from room temperature to 200 °C, and keep it for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com