Method for purifying potassium iodide from perfluoroalkylethyl acrylate byproduct

A technology of perfluoroalkyl ethyl acrylate and potassium iodide, which is applied in chemical instruments and methods, purification of alkali metal halides, preparation of carboxylate, etc. It can solve the problem of large C-F bond energy, high environmental pressure, residual organic matter, etc. Problems, to achieve high added value, cost savings, avoid waste and pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

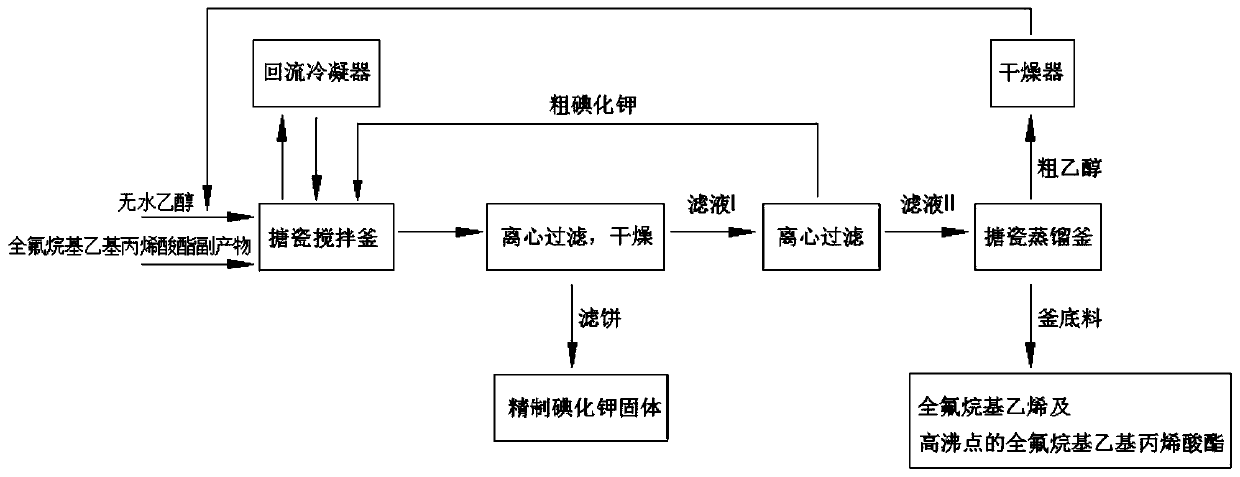

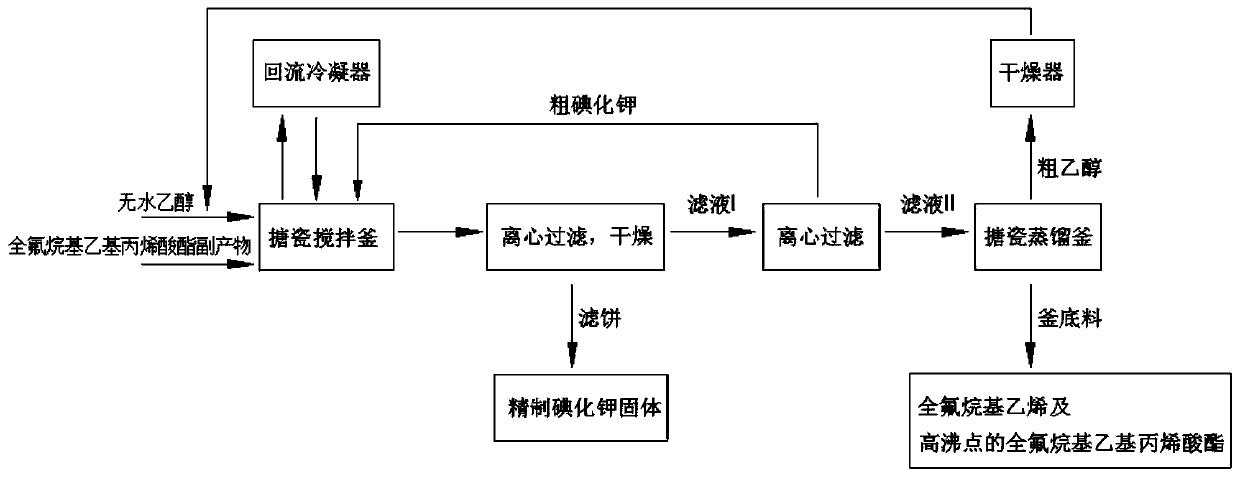

Image

Examples

Embodiment 1

[0033] A method for purifying potassium iodide from the by-product of perfluoroalkyl ethyl acrylate, the method comprising the following steps:

[0034] (1) Washing:

[0035] Take 100 kilograms of by-products from the synthesis reaction of perfluoroalkyl ethyl acrylate, and add crude potassium iodide with 75% potassium iodide content to a 500-liter enamel stirred tank, then add 150 kilograms of absolute ethanol, turn on the stirring, and jacket heating steam. When the temperature in the kettle reaches 78°C, the system will reflux, and continue stirring for 1 hour under reflux;

[0036] (2) Centrifugal:

[0037] After refluxing for 1 hour, stop heating, and pass cooling water into the jacket to cool the crude potassium iodide solution in the enamel stirred tank. When the temperature of the materials in the enamel stirred tank drops to 60°C, put the materials in the centrifuge for centrifugal filtration. Obtain refined potassium iodide solid I and filtrate I;

[0038] (3) Drying:

[0039...

Embodiment 2

[0044] A method for purifying potassium iodide from the by-product of perfluoroalkyl ethyl acrylate, the method comprising the following steps:

[0045] (1) Washing:

[0046] Take 100 kilograms of by-products from the synthesis of perfluoroalkyl ethyl acrylate and add crude potassium iodide with 75% potassium iodide content to a 500-liter enamel stirred tank, then add 150 kilograms of absolute ethanol, turn on the stirring, and jacket heating steam. When the temperature in the kettle reached 78°C, the system refluxed, and stirring was continued for 1 hour under reflux.

[0047] (2) Centrifugal:

[0048] After refluxing for 1 hour, stop heating, and pass cooling water into the jacket to cool the crude potassium iodide solution in the enamel stirred tank. When the temperature of the material in the enamel stirred tank drops to 60°C, put the material in the centrifuge for centrifugal filtration. Obtain refined potassium iodide solid I and filtrate I;

[0049] (3) Re-washing and centrifug...

Embodiment 3

[0057] A method for purifying potassium iodide from the by-product of perfluoroalkyl ethyl acrylate, the method comprising the following steps:

[0058] (1) Washing:

[0059] Take 100 kilograms of by-products from the synthesis of perfluoroalkyl ethyl acrylate and add crude potassium iodide with 75% potassium iodide content to a 500-liter enamel stirred tank, then add 150 kilograms of absolute ethanol, turn on the stirring, and jacket heating steam. When the temperature in the kettle reached 78°C, the system refluxed, and stirring was continued for 1 hour under reflux.

[0060] (2) Centrifugal:

[0061] After refluxing for 1 hour, stop heating, and pass cooling water into the jacket to cool the crude potassium iodide solution in the enamel stirred tank. When the temperature of the material in the enamel stirred tank drops to 60°C, put the material in the centrifuge for centrifugal filtration. Obtain refined potassium iodide solid I and filtrate I;

[0062] (3) Re-washing and centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com