Material rapid-heating device of reciprocating plate pusher

A rapid heating and pushing machine technology, applied in the field of heating devices, can solve the problems of time-consuming and other problems, and achieve the effects of good tensile strength, high product density and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

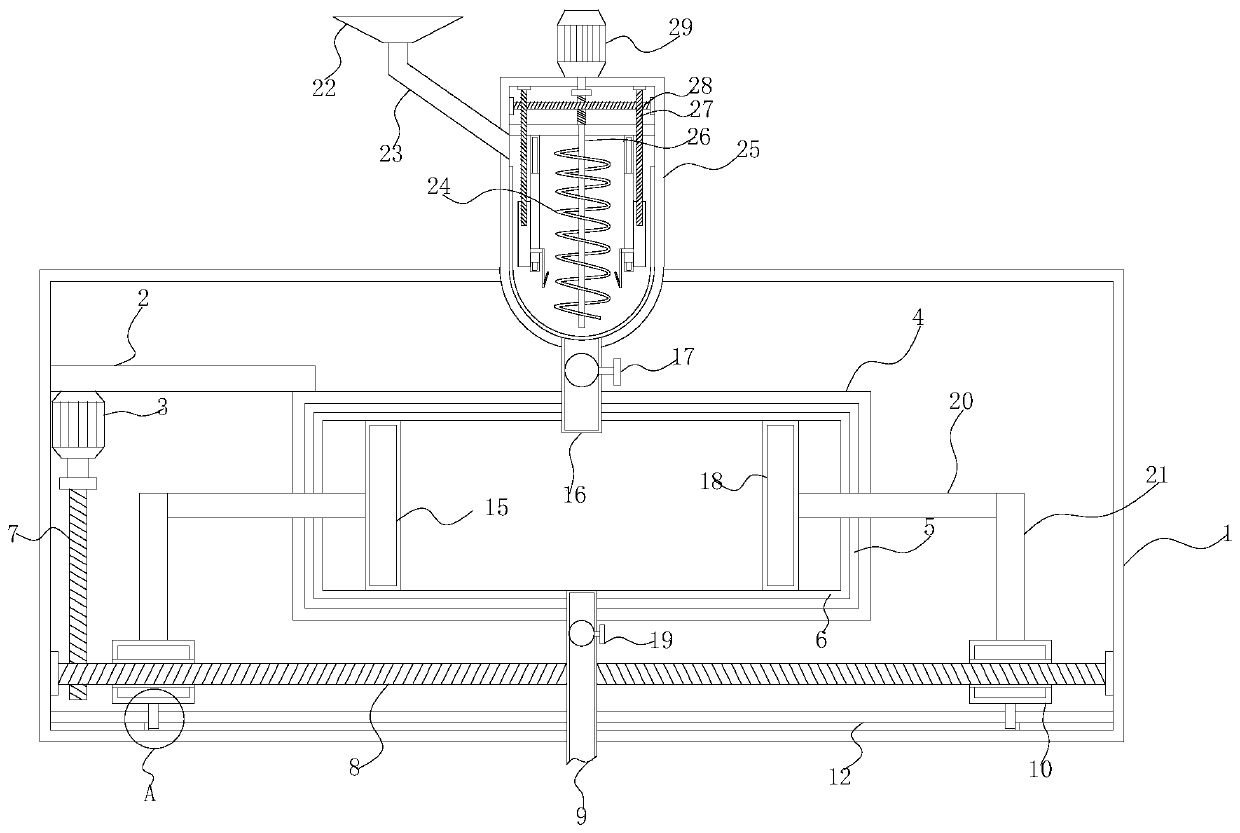

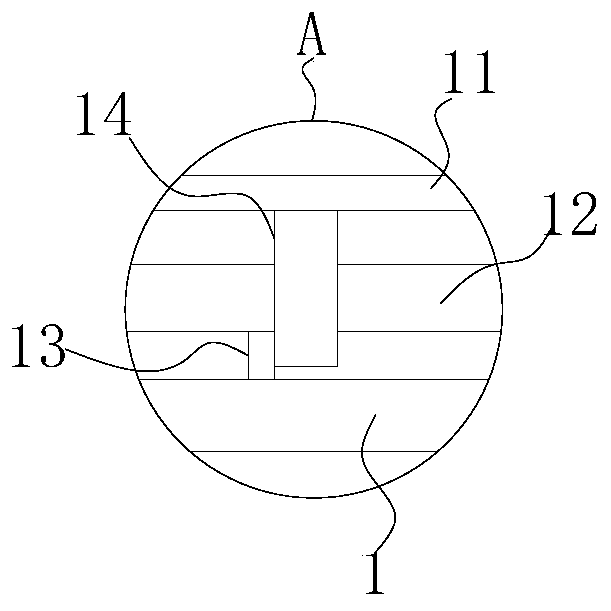

[0022] Such as Figure 1-5As shown, the present invention provides a technical solution: a material rapid heating device of a reciprocating pusher, comprising a box body 1, the inner wall of the box body 1 is fixedly connected with a connecting plate 2, and the bottom of the connecting plate 2 is fixedly connected with the outer wall of the casing 4 , the inner wall of the shell 4 is bonded with a heat insulating layer 5, and the layer of the heat insulating layer 5 away from the shell 4 is bonded with an inner shell 6, and the bottom of the connecting plate 2 is fixedly installed with a motor one 3, and the motor one 3 is a servo forward and reverse motor, The output end of the motor one 3 is fixedly connected with one end of the screw rod one 7 through the coupling one, the inside of the box body 1 is provided with a screw rod 8, and the surface of the screw rod 8 is provided with two sections of opposite threads, and the screw rod one 7 is threadedly connected with the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com