A zipper threading slider machine

A technology of threading and pulling machine and pulling head, applied in clothing, sliding fastener components, applications, etc., can solve the problem of affecting the efficiency of threading, the consumption of large driving energy by the cylinder of threading, and affecting the service life accuracy of other parts of the machine, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited to the following specific examples.

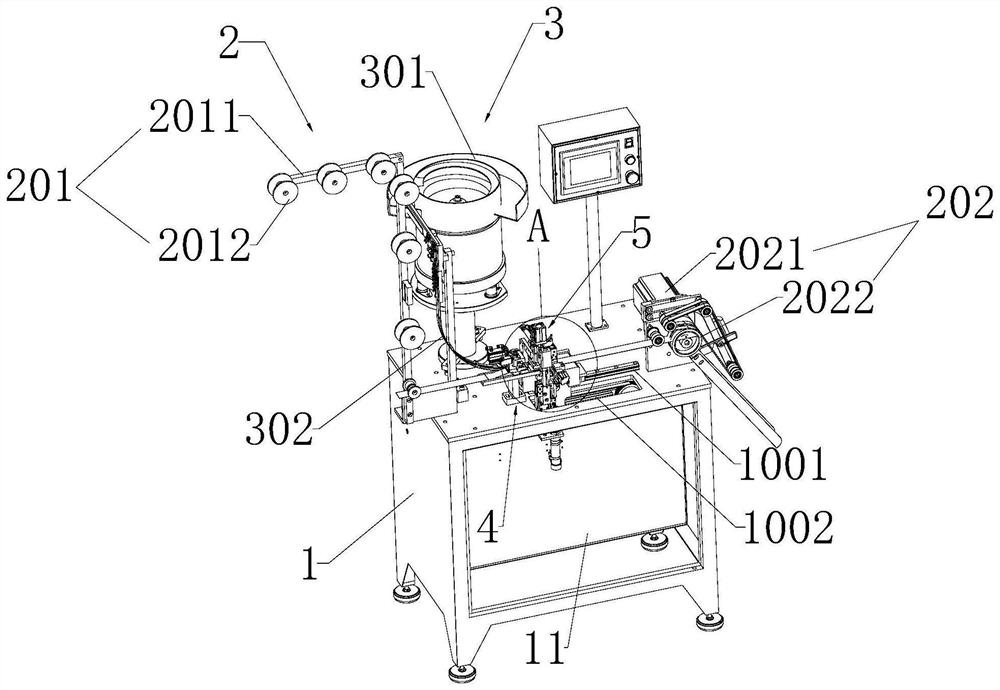

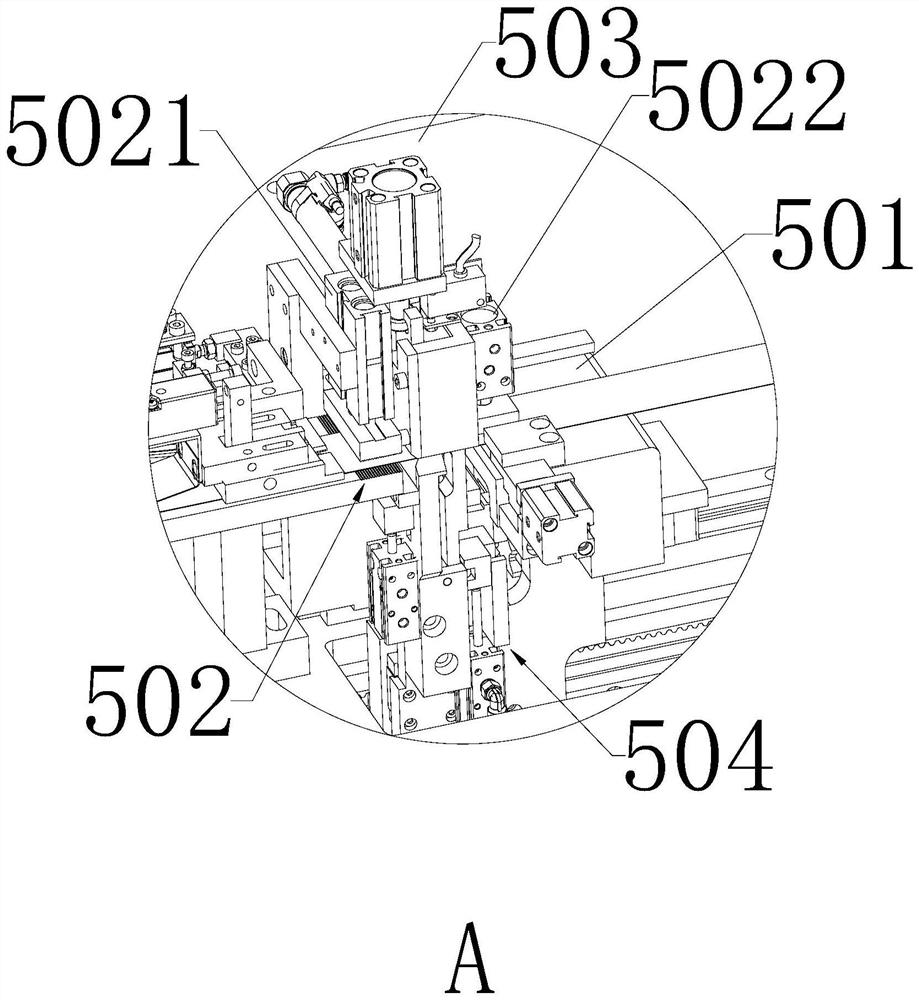

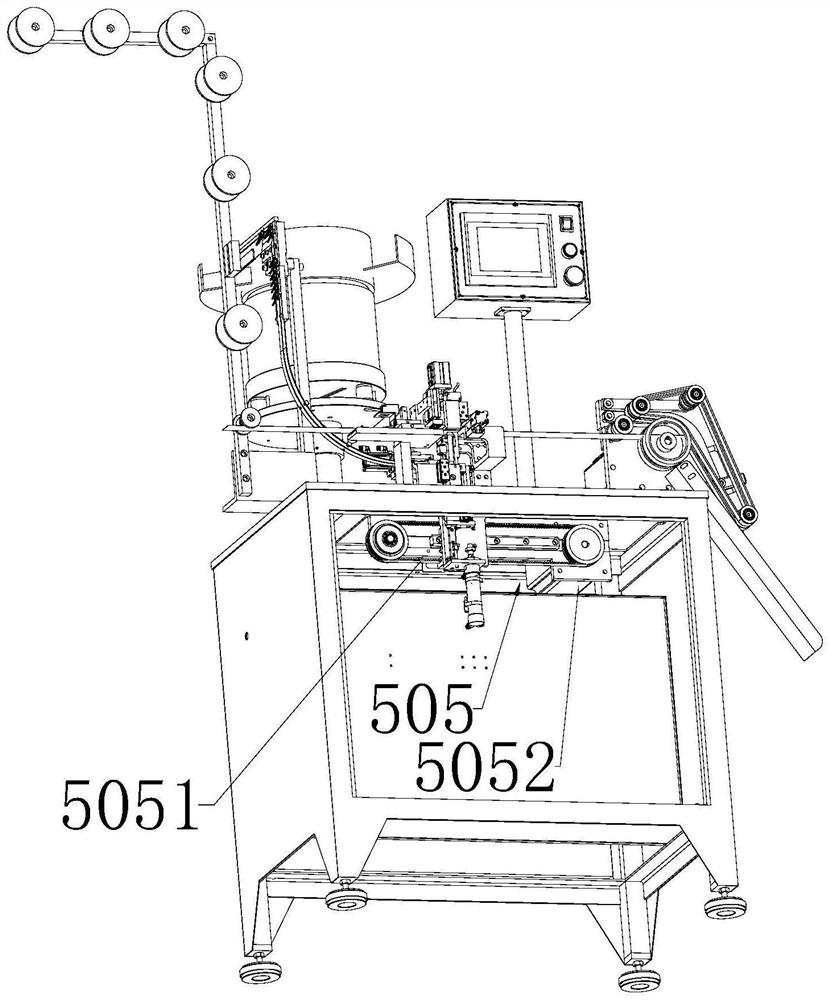

[0050] refer to figure 1 , this embodiment discloses a zipper threading slider machine, including a frame 1, on which a chain belt feeding assembly 2, a slider feeding assembly 3, a chain belt gap detection assembly 4 and a slider threading assembly 5 are arranged, The chain feeder assembly 2 feeds the fastener stringer 12 in the horizontal direction.

[0051] refer to figure 1 The chain feeding belt assembly 2 includes a front guide pulley set 201 and a rear dragging belt assembly 202, the front guide pulley set includes a chain guide frame 2011 fixedly arranged on the frame 1 and a plurality of chain guide wheels rotatably arranged on the chain guide frame 2011 2012, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com