Hydrothermal carbon sphere for supporting nanosilver by using one-step method and preparation method and application of hydrothermal carbon sphere

A technology of nano-silver and hydrothermal carbon, which is applied in the direction of botany equipment and methods, applications, and preservation of fruits and vegetables, and can solve problems such as poor adhesion, easy agglomeration and instability of nano-silver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

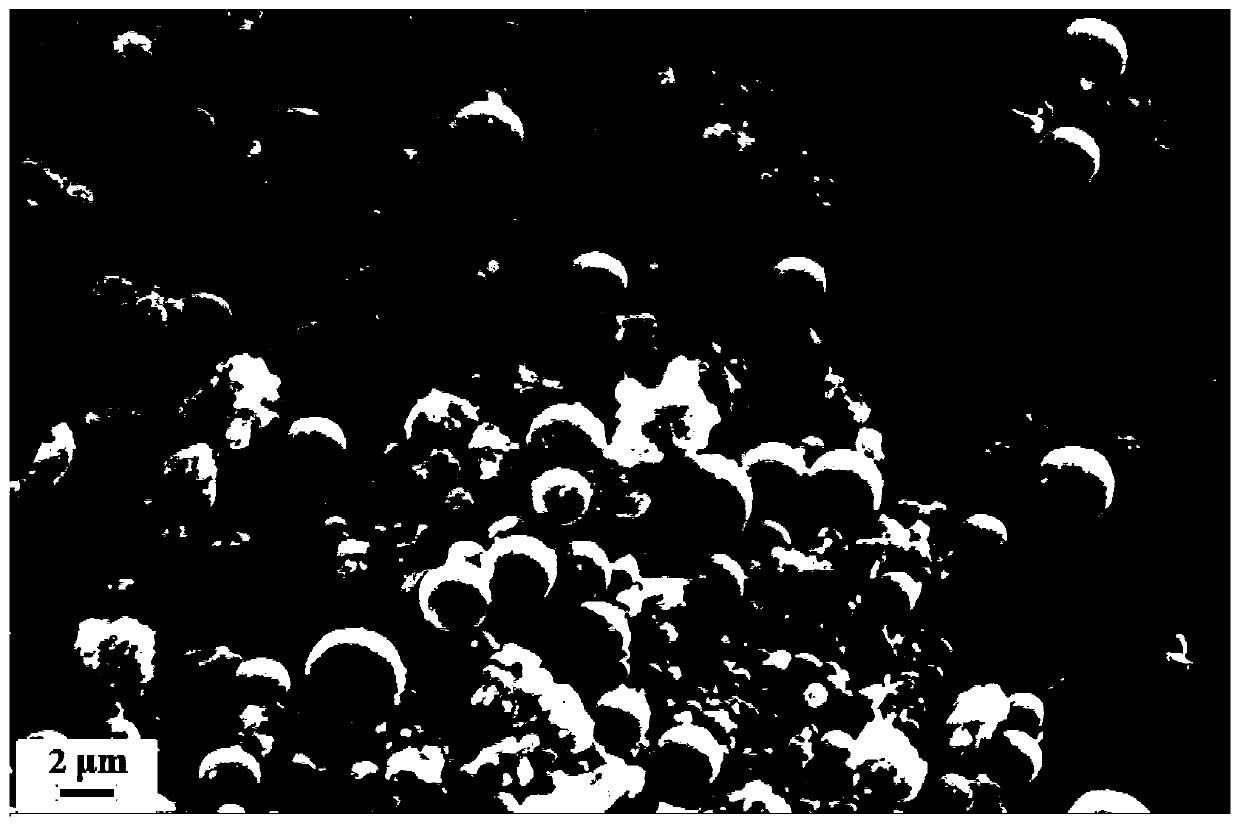

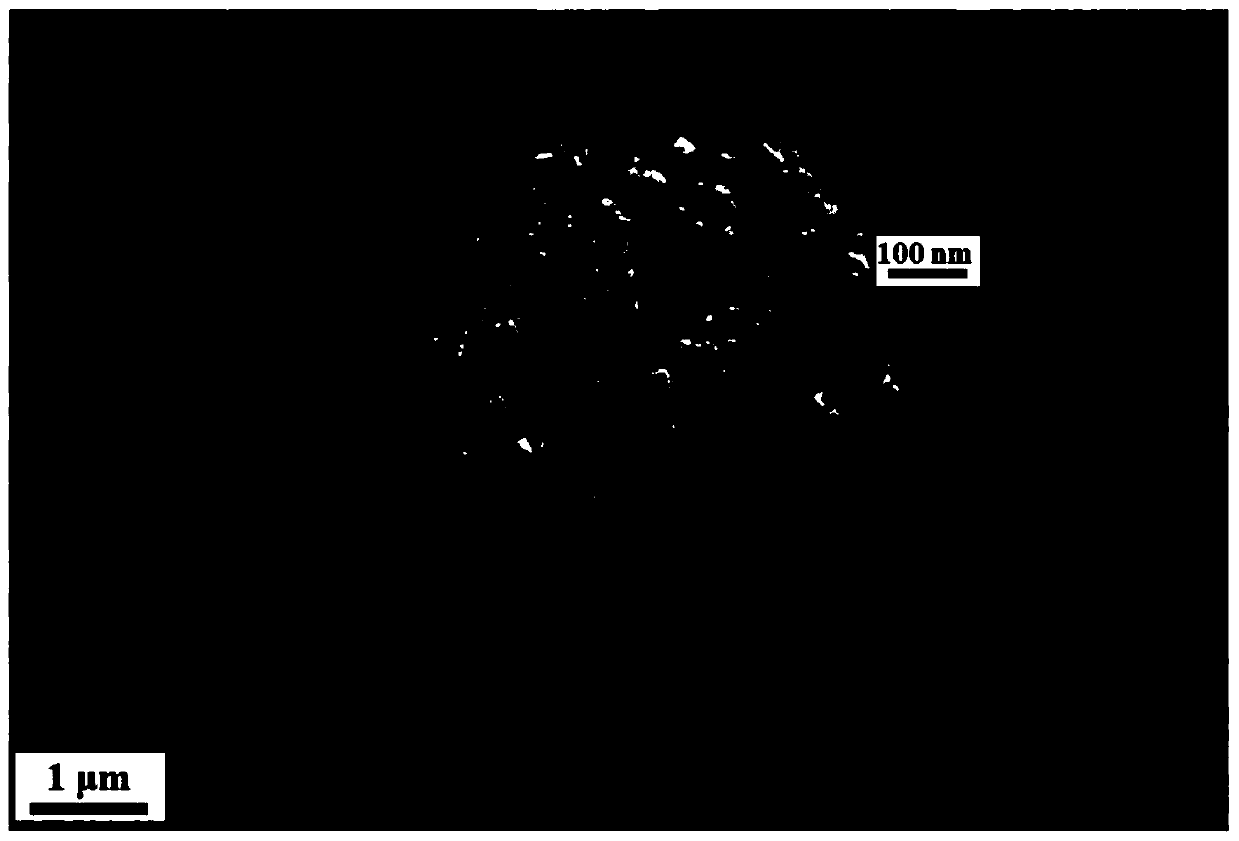

Image

Examples

Embodiment 1

[0034] After the freshly collected corn stalks were dried, the leaves and roots were removed, and the hydrothermal carbon spheres loaded with nano-silver were prepared according to the following steps:

[0035] (1) Grinding corn stalks and ball milling pretreatment, the adjustable speed ball mill is MITR-YXQM-1L planetary ball mill, the pretreatment conditions are: the pulverizer grinds the raw material to 40 mesh, the ball mill speed is 220rpm, and the ball milling time is 8h to obtain particles shaped corn stalks;

[0036] (2) Dissolving the corn stalk particles in the sodium hydroxide / urea system, the mass ratio of sodium hydroxide, urea and water in the sodium hydroxide / urea system is 5:10:85, the volume of the sodium hydroxide / urea system 100mL, the dissolution conditions are: temperature -15°C, time 4h, dosage of corn stalks 0.5g;

[0037] (3) Add the prepared silver-ammonia solution dropwise into the solution dissolved in the above step (2), and mix evenly. The additio...

Embodiment 2

[0041] The freshly collected wheat straw raw materials were dried, leaves and roots removed, and the hydrothermal carbon spheres loaded with nano-silver were prepared according to the following steps:

[0042] (1) Grinding and ball milling the wheat straw for pretreatment. The adjustable speed ball mill is MITR-YXQM-1L planetary ball mill. The pretreatment conditions are: the pulverizer grinds the raw material to 40 mesh, the speed of the ball mill is 220rpm, and the ball milling time is 8h to obtain particles. shaped wheat straw;

[0043] (2) Dissolve the particles in the sodium hydroxide / urea system, the mass ratio of sodium hydroxide, urea and water in the sodium hydroxide / urea system is 5:10:85, and the volume of the sodium hydroxide / urea system is 100mL , the dissolution conditions are: temperature -15°C, time 4h, dosage of wheat straw granules 0.5g;

[0044] (3) Add the prepared silver-ammonia solution dropwise into the solution dissolved in the above step (2), and mix ...

Embodiment 3

[0048] After the freshly collected bagasse was dried to remove impurities such as dust, the hydrothermal carbon spheres loaded with nano-silver were prepared according to the following steps:

[0049] (1) The bagasse is pulverized and pretreated by ball milling. The adjustable speed ball mill is MITR-YXQM-1L planetary ball mill. The pretreatment conditions are: the pulverizer pulverizes the raw material to 50 mesh, the ball mill speed is 210rpm, and the ball milling time is 9h to obtain granular bagasse;

[0050] (2) Dissolving the particles in the sodium hydroxide / urea system, the mass ratio of sodium hydroxide, urea and water in the sodium hydroxide / urea system is 6:11:83, the volume of the sodium hydroxide / urea system is 110mL, The dissolution conditions are: temperature -15°C, time 5h, bagasse granule dosage 1g;

[0051] (3) Add the prepared silver-ammonia solution dropwise into the solution dissolved in the above step (2), and mix evenly. The addition conditions of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com