Direct shearing test device for rock and earth mass bulk materials under freezing and thawing conditions and test method thereof

A technology for bulk materials and testing devices, which is applied to measuring devices, using stable shear force to test the strength of materials, analyzing materials, etc., to achieve the effects of not affecting production, accurate experimental data, and simple principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

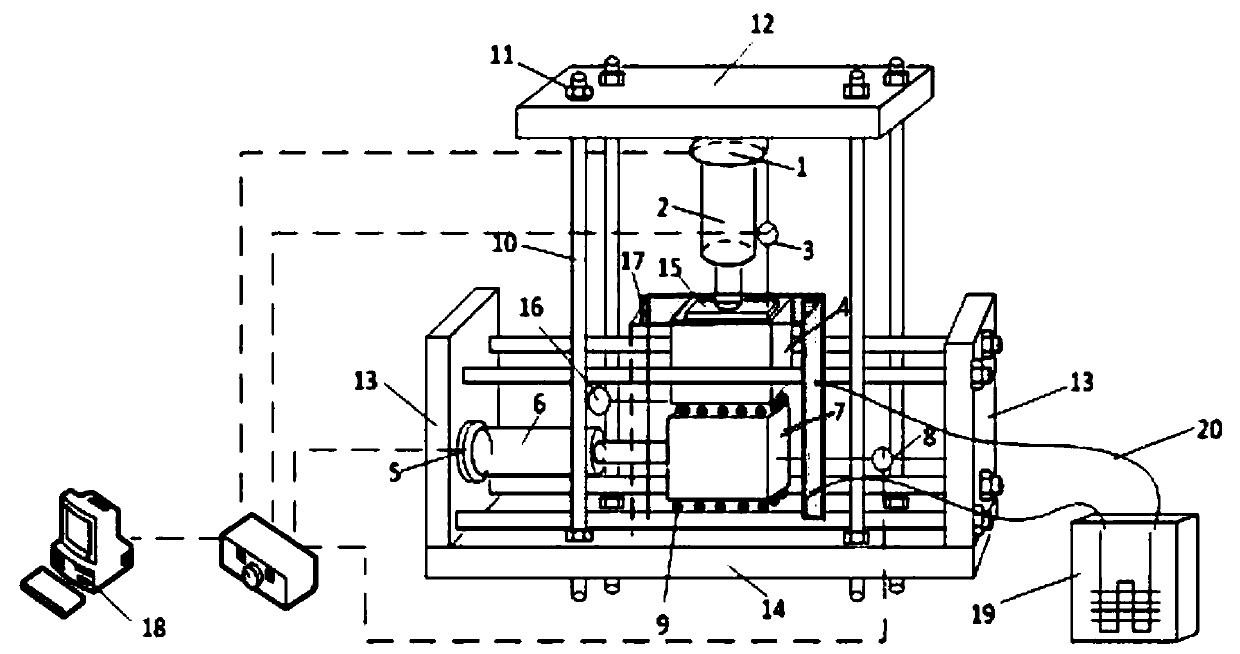

[0024] The specific technical solutions of the present invention are described in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, the direct shear test device for rock-soil bulk materials under freeze-thaw conditions includes:

[0026] Stress loading system, including vertical continuous loading system 2 and horizontal continuous loading system 6;

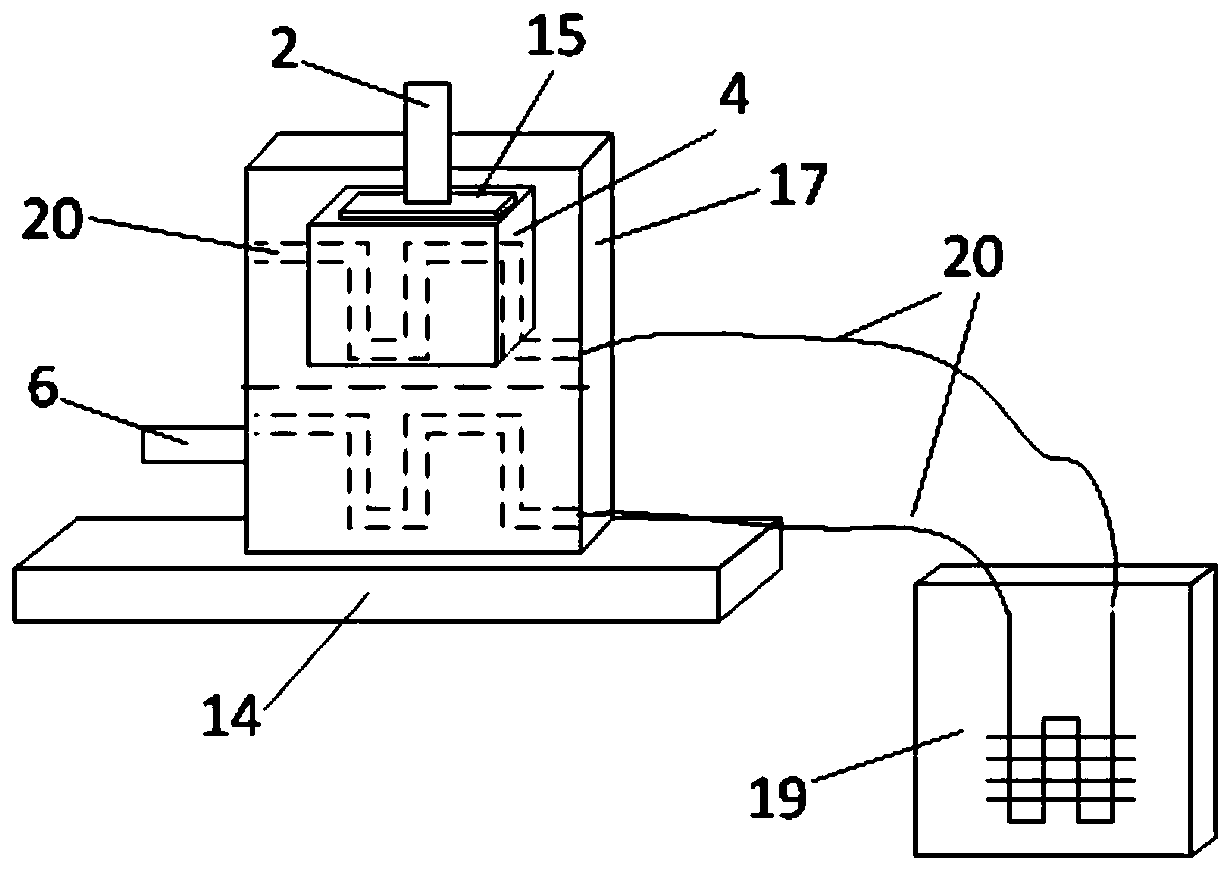

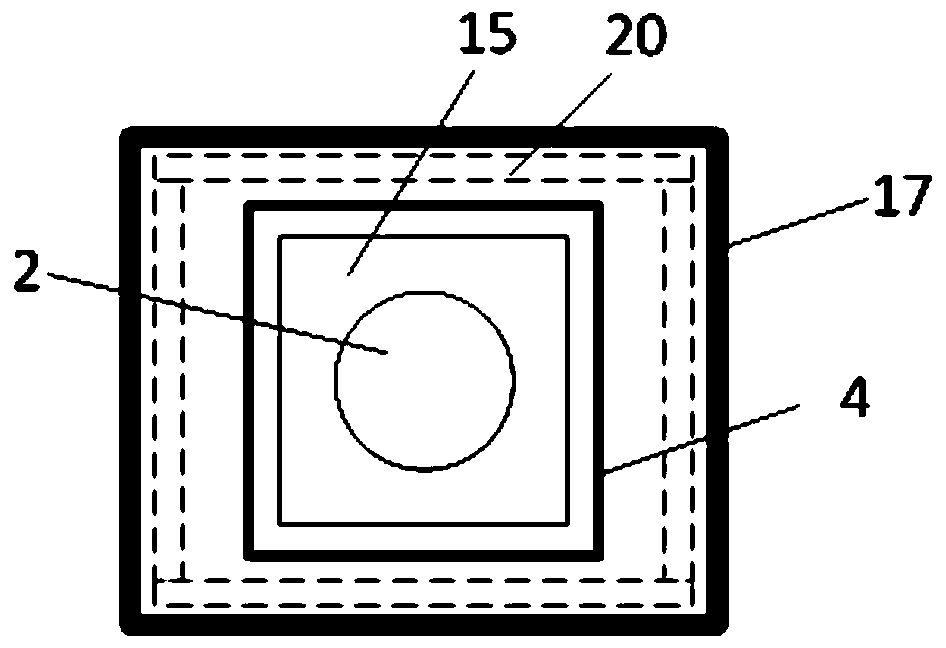

[0027] Specimen control system, comprising a base 14 and an upper shear box 4 and a lower shear box 7 for loading samples, such as figure 2 and image 3 As shown, the upper shear box 4 and the lower shear box 7 are relatively arranged up and down to form the shear box; the upper shear box 4 and the lower shear box 7 are connected with steel balls 9, as Figure 5 As shown, the lower shear box 7 is connected with the base 14 with a steel ball 9; the loading piston plate 15 is located above the upper shear box 4, and there is a gap between the two; it also includes an axial pressure steel plate 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com