Generator set cooling air duct structure

A technology for cooling air ducts and generator sets, which is applied in the direction of engine cooling, cooling/ventilation devices, electric components, etc., which can solve the problems of poor cooling effect, loud noise, etc., and achieve the goal of optimizing the cooling path and improving the cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

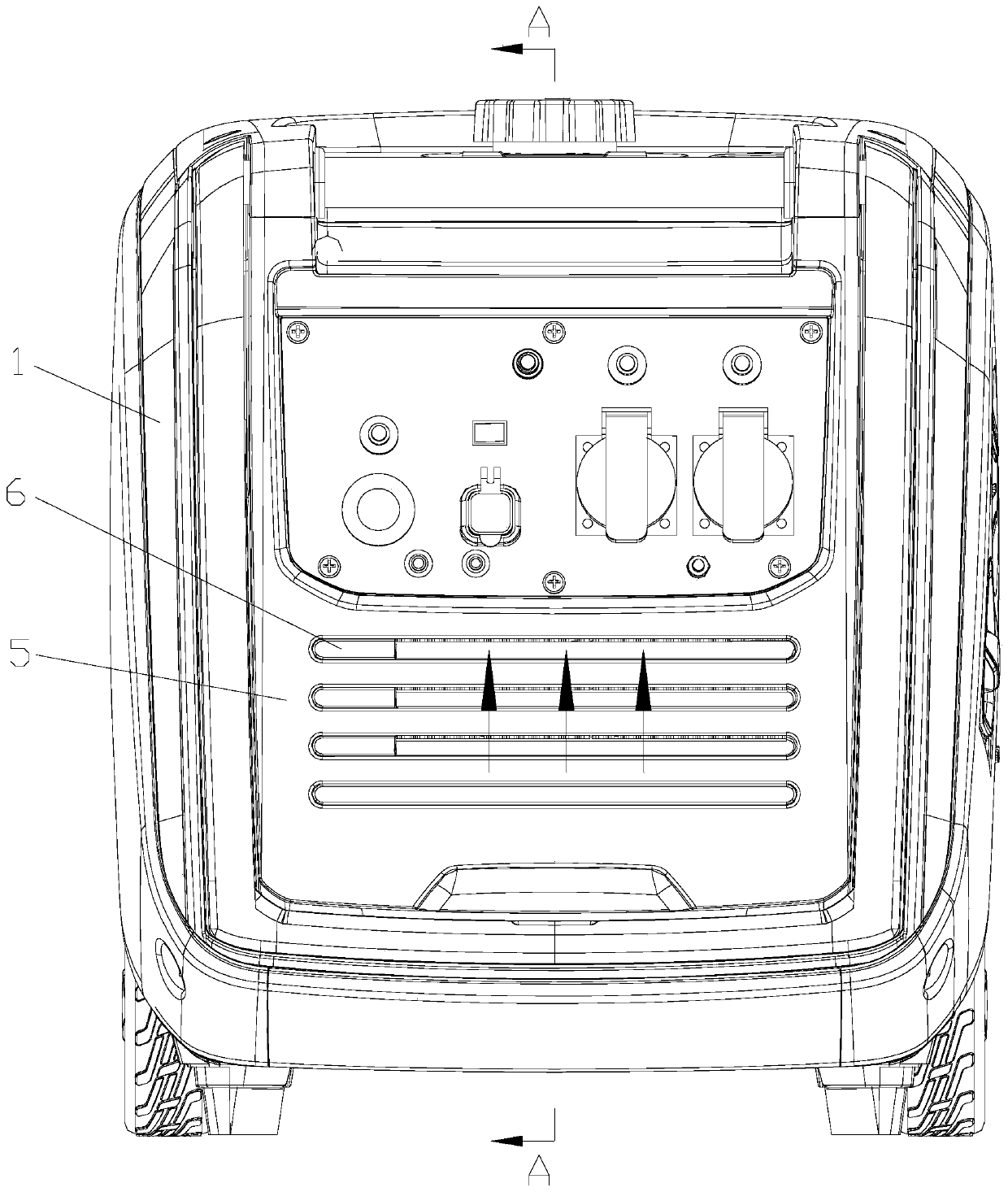

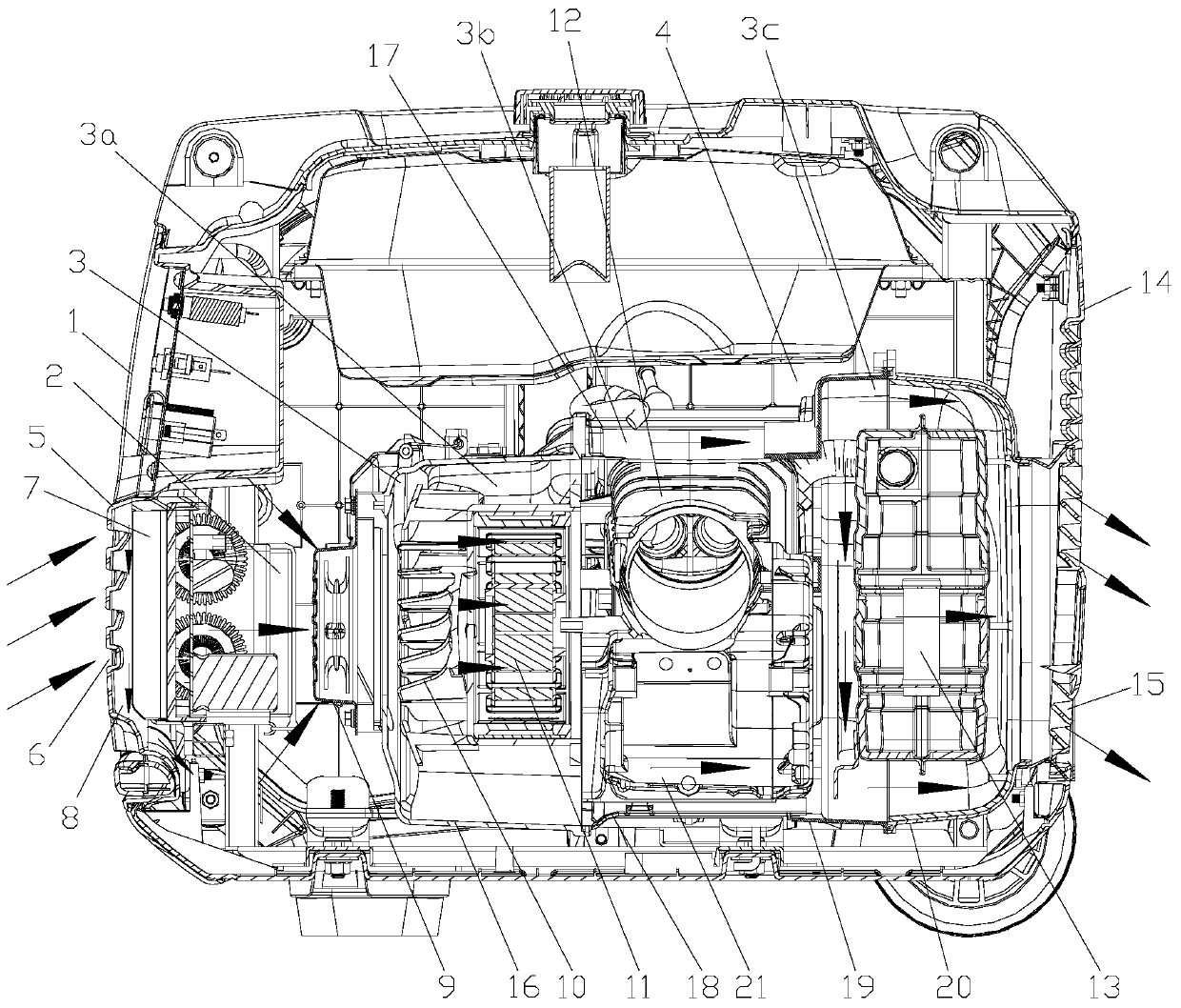

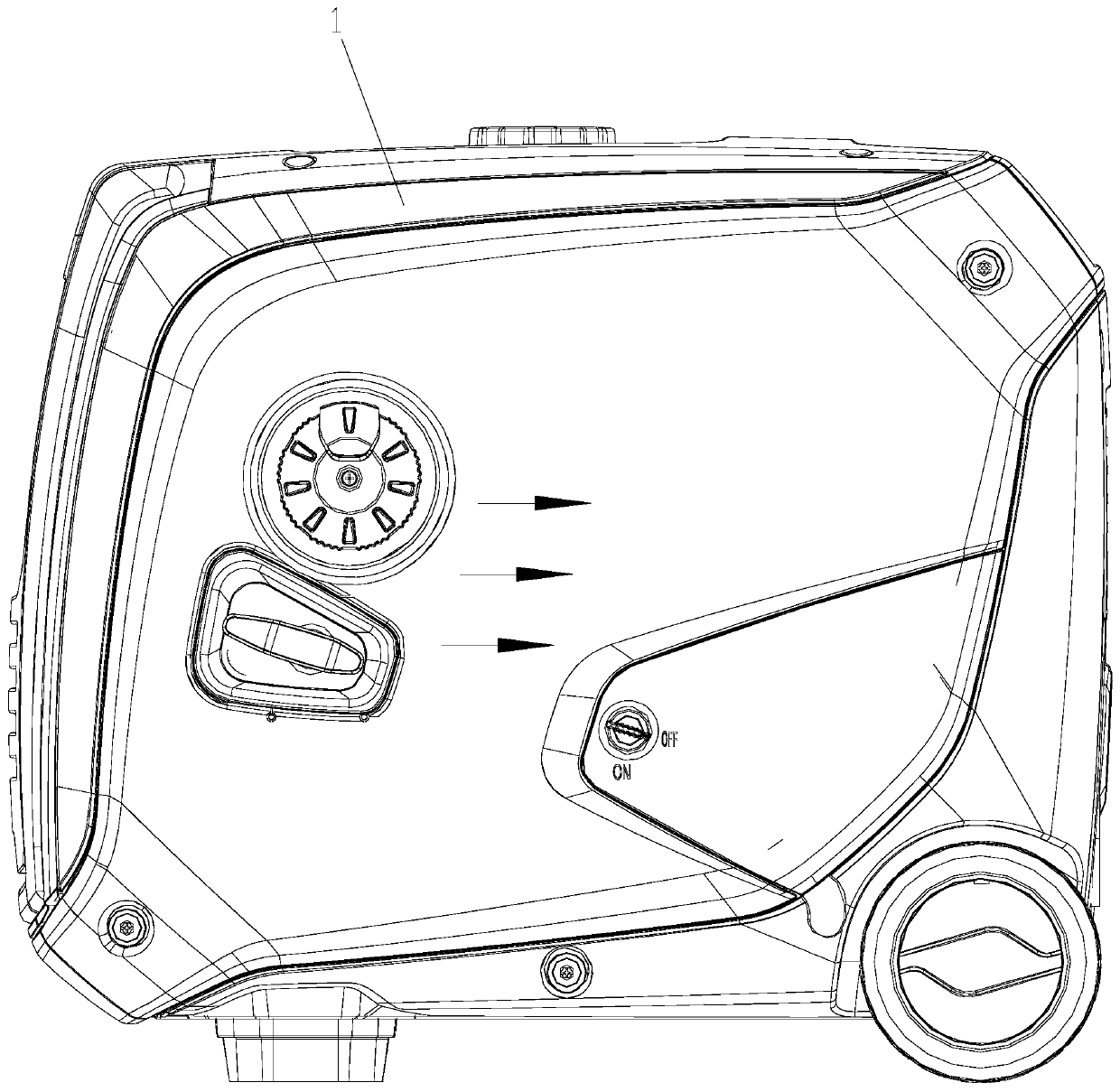

[0021] like Figure 1 to Figure 4 As shown: the structure of the cooling air duct of the generator set in this embodiment includes a housing 1 with an inner cavity. The front and rear sides of the inner cavity of the housing 1 are respectively opened to form an air inlet side and an air outlet side. The inner cavity An air guide assembly is arranged inside, and cooling passages respectively connected with the air inlet side and the air outlet side are formed inside the air guide assembly, and the impeller 10, the generator 11. The engine 12 and the muffler 13, the cooling channel includes the cooling air channel I3 passing through the air inlet side and the air outlet side and the cooling air channel II21 formed between the bottom of the engine 12 and the air guide assembly, the outer wall of the air guide assembly Cooling air passages III4 for cooling the side and top of the engine are formed between the two sides and the top and the inner cavity wall of the housing 1. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com