Unit type constant-resistance elastic yielding anti-impact hydraulic support and working method thereof

A hydraulic support and unitized technology, applied in the direction of pillars/supports, earth square drilling, mining equipment, etc., can solve problems such as roof fall accidents, replacement only, secondary damage, etc., to improve work efficiency, reduce equipment losses, The effect of preventing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

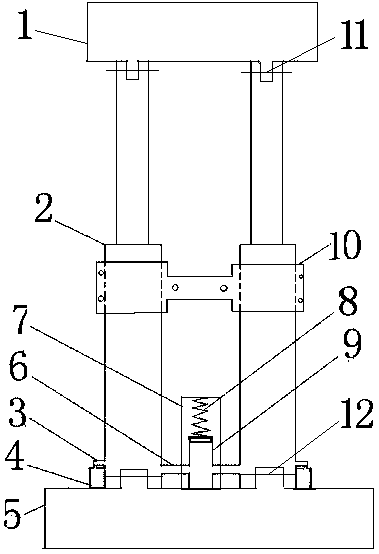

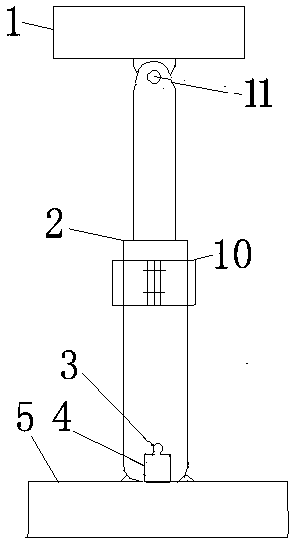

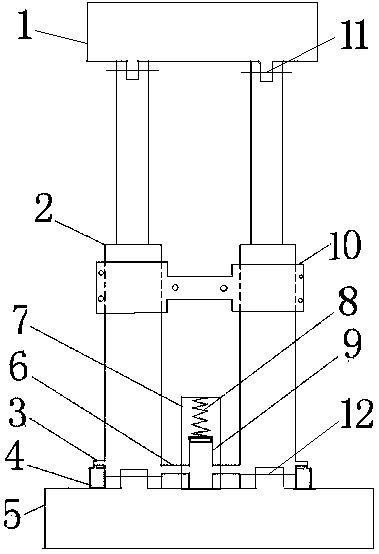

[0021] Such as figure 1 , 2 As shown, a double-column constant-resistance elastic yielding pressure anti-shock hydraulic support is composed of a support top beam 1, a support base 5, a double hydraulic column 2 and a safety valve 4, and a fixing device 10 is arranged between the double hydraulic columns 2. The emulsion chamber of the hydraulic column 2 is connected to the safety valve 4 through the high-pressure pipe 3, and the working pressure of the safety valve 4 is 40Mpa; wherein, an energy storage device is installed on the bracket base 5; the energy storage device is A hydraulic jack 9 is provided in an energy storage chamber 7, and a pressure spring 8 is provided on the top surface of the hydraulic jack 9. The liquid chamber of the hydraulic jack 9 communicates with the liquid chamber of the double hydraulic column 2 through a large-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com