Washing equipment and washing water outlet method

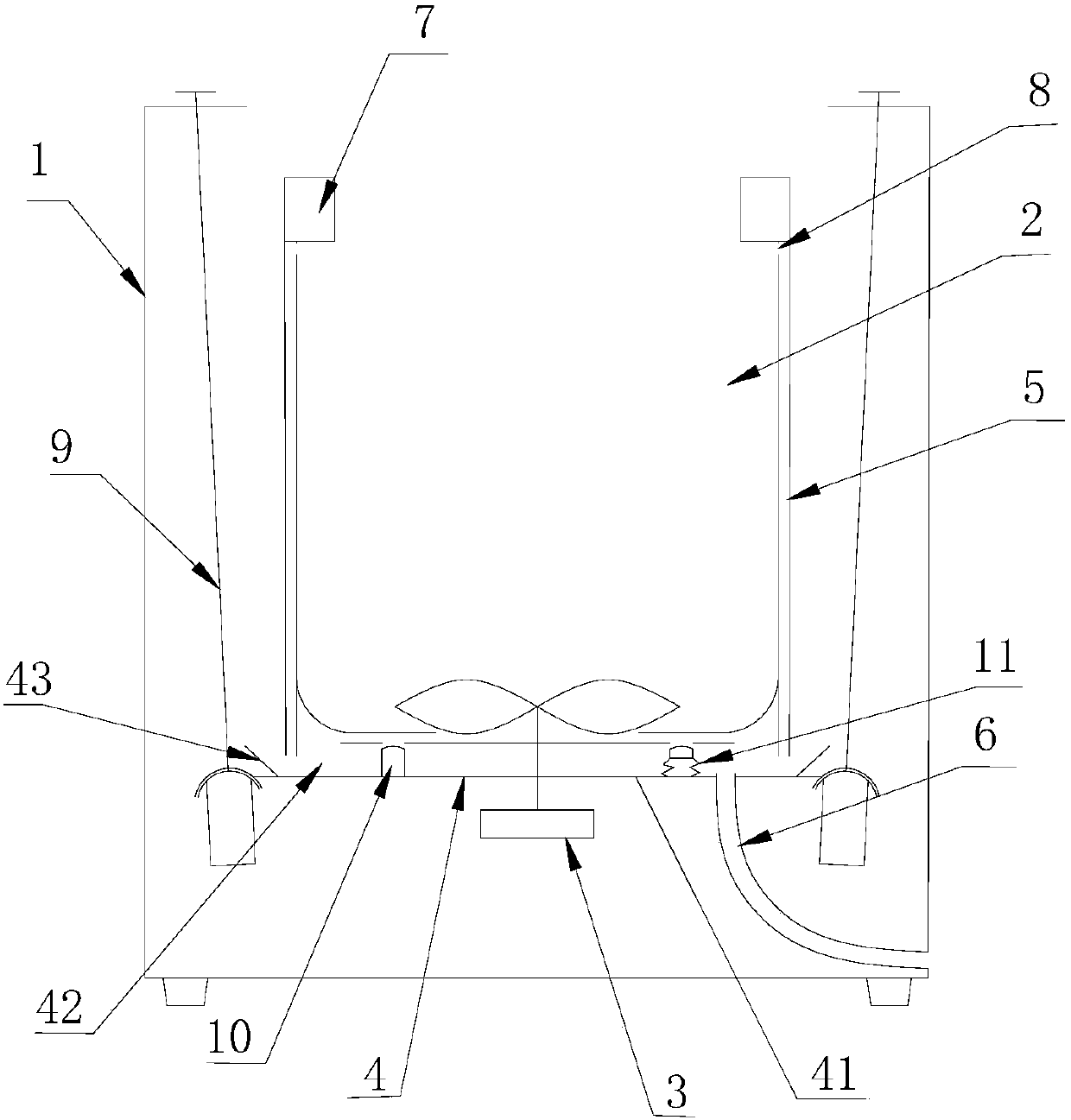

A technology for washing equipment and washing buckets, which is applied in the field of washing, can solve the problems of raising the overall center of gravity of the washing bucket and the outer bucket, destroying the washing bucket, and unfavorable environmental protection, and achieves the effects of improving water outlet efficiency, long service life, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

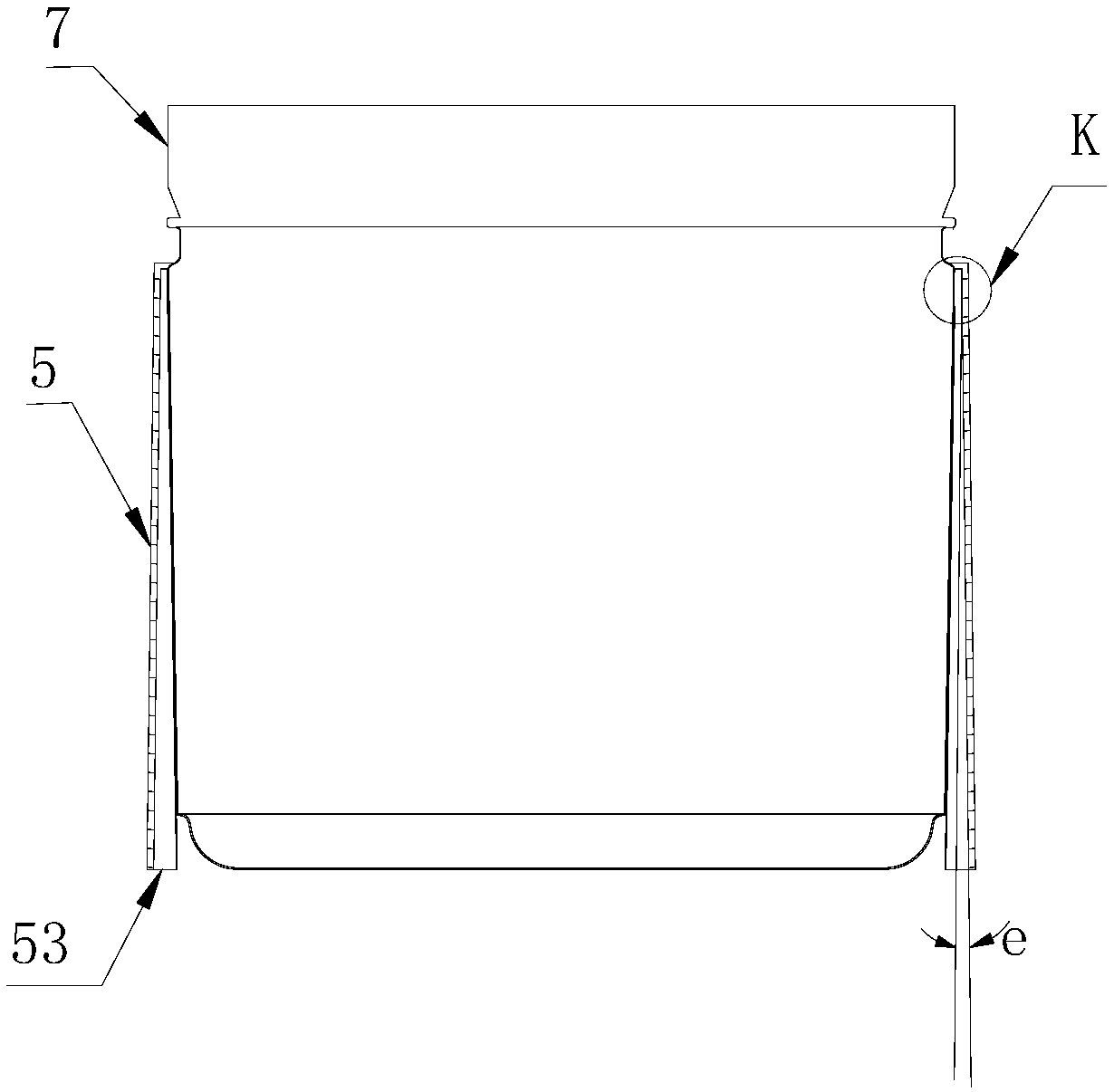

[0055] Such as figure 2 and Figure 5 As shown, the water outlet guide member 5 in this embodiment is provided with a top-down water guide chamber 51, the upper part of which communicates with the water outlet 8, and the radial width of the water guide chamber 51 gradually increases from top to bottom. .

Embodiment 2

[0057] Such as figure 2 As shown, the water outlet guide part 5 in this embodiment is provided with a top-down water guide chamber 51, the upper part of which communicates with the water outlet 8, and the side wall of the water guide chamber 51 away from the washing tub 2 is formed from the top It is set to be inclined downward gradually in a direction away from the washing tub 2, and the inclination angle e is 3°. The above structure is beneficial to the speed of washing water being discharged downwards, and can prevent the washing water from flowing downwards in the water-conducting chamber due to the centrifugal force of the washing tub, or even gather upwards near the water outlet.

Embodiment 3

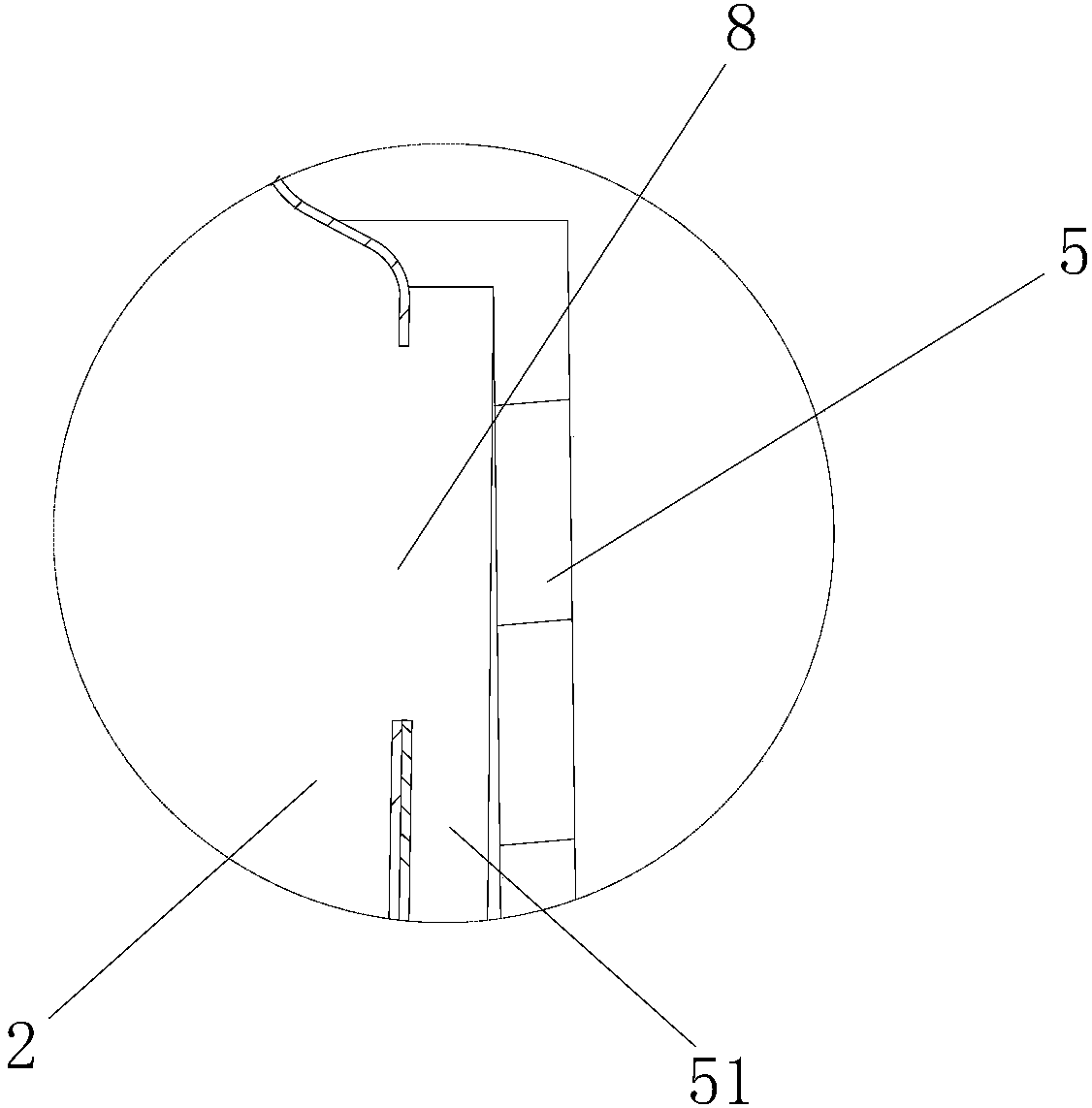

[0059] Such as image 3 As shown, the orientation of the water outlet 8 in this embodiment is set along the radial direction of the washing tub 2 . This structure is beneficial to the discharge of washing water, and the radial direction of the water outlet 8 can increase the speed of washing water throwing out relative to the water outlet structure that discharges the washing tub upwards by utilizing the centrifugal force of the washing tub rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com