Adhesive tape, electrochemical device containing the adhesive tape

An electrochemistry and tape technology, applied in the field of electrochemistry, can solve the problems of battery thermal runaway, battery heat generation, lithium evolution, etc., and achieve the effect of strong resistance to electrolyte corrosion and improved overcharge safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] How to make tape:

[0050] Select suitable insulating viscous polymer material and suitable plasticizing material as the matrix material, select conductive carbon black Super P as the conductive material, and dissolve the two in toluene solution according to the ratio of Super P: matrix material = 99:1 by weight , mix evenly, apply it on the PET release film by a coating machine, and apply a certain thickness (1 μm) to form a conductive layer. Then coat a matrix material layer with a certain thickness (1 μm) on the surface of the conductive layer to form the first adhesive layer. Transfer the two-layer structure to the PET release film, the first adhesive layer is to the PET release film, and then coat a matrix material layer with a certain thickness (1 μm) on the other surface of the conductive layer to form the second adhesive layer. Paste a release film on the second bonding layer to obtain a temperature-sensitive conductive adhesive tape.

[0051] The lithium io...

Embodiment 2-8

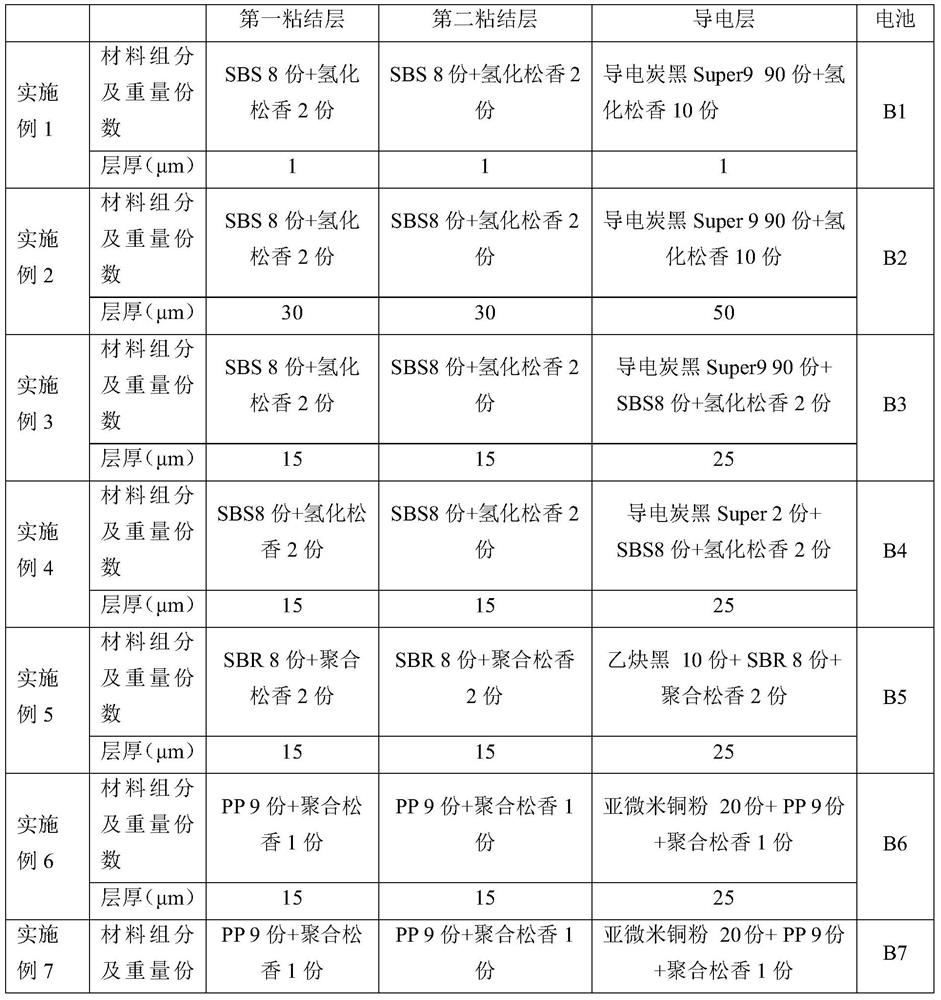

[0070] Examples 2-8 The adhesive tape and battery were prepared according to the method of Example 1. The material components and parts by weight in each layer of the adhesive tape and the thickness of each layer are shown in Table 1.

[0071] Table I

[0072]

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com