Surface treatment composition containing fluorinated polyether siloxane

A technology of fluorinated polyether siloxane and surface treatment, applied in the field of surface treatment and surface treatment composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

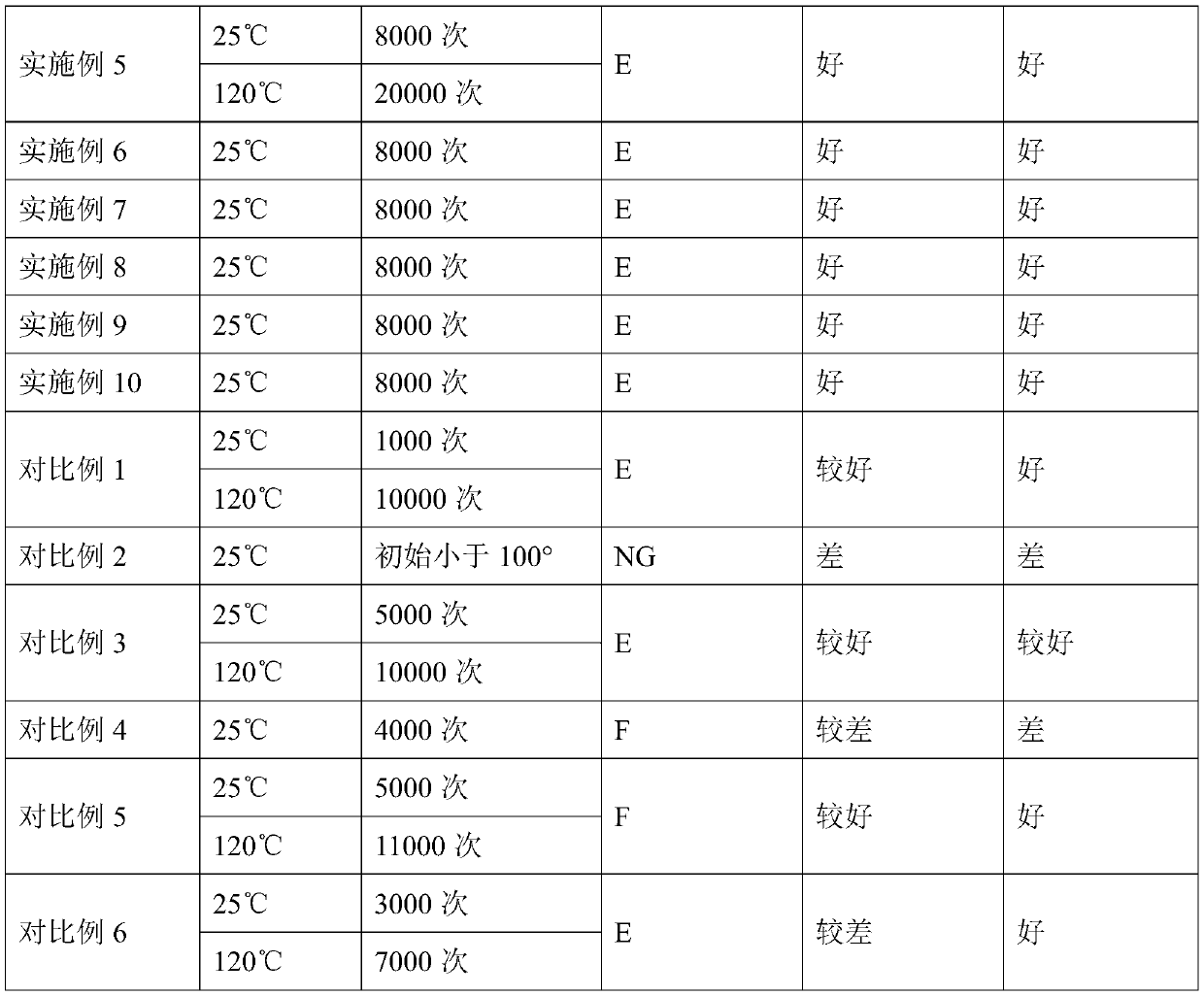

Examples

Embodiment 1

[0057] Dissolve 90 parts by mass of fluorinated polyether siloxane A) and 10 parts by mass of aminosiloxane compound H into hydrofluoroether solvent 347, and prepare a test solution with a concentration of 1 wt‰.

[0058] The configuration methods of Examples 2-10 and Comparative Examples 1-6 are the same as that of Example 1, and the specific ratio of active ingredients is shown in Table 1.

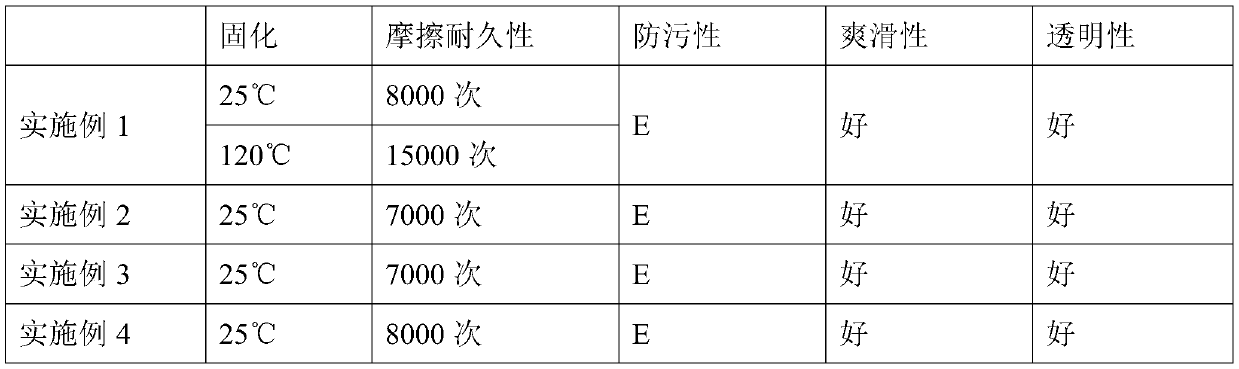

[0059] Table 1: Active ingredient distribution ratio (all are mass parts in the table)

[0060] Example A B C D E F G H 1 90 10 2 70 30 3 99.9 0.01 4 85 15 5 85 15 6 85 15 7 68 17 15 8 68 17 15 9 55.25 29.75 15 10 68 17 15 5 comparative example 1 100 2 50 50 3 68 32 4 68 16 16 5 54.5 30.5 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com