Device and process for producing sulfuric acid

A technology for preparing sulfuric acid, which is applied in the field of sulfuric acid preparation equipment and technology, can solve the problems of long process, high energy consumption, and large investment, and achieve the effects of high recovery efficiency, low energy consumption, and high environmental protection indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

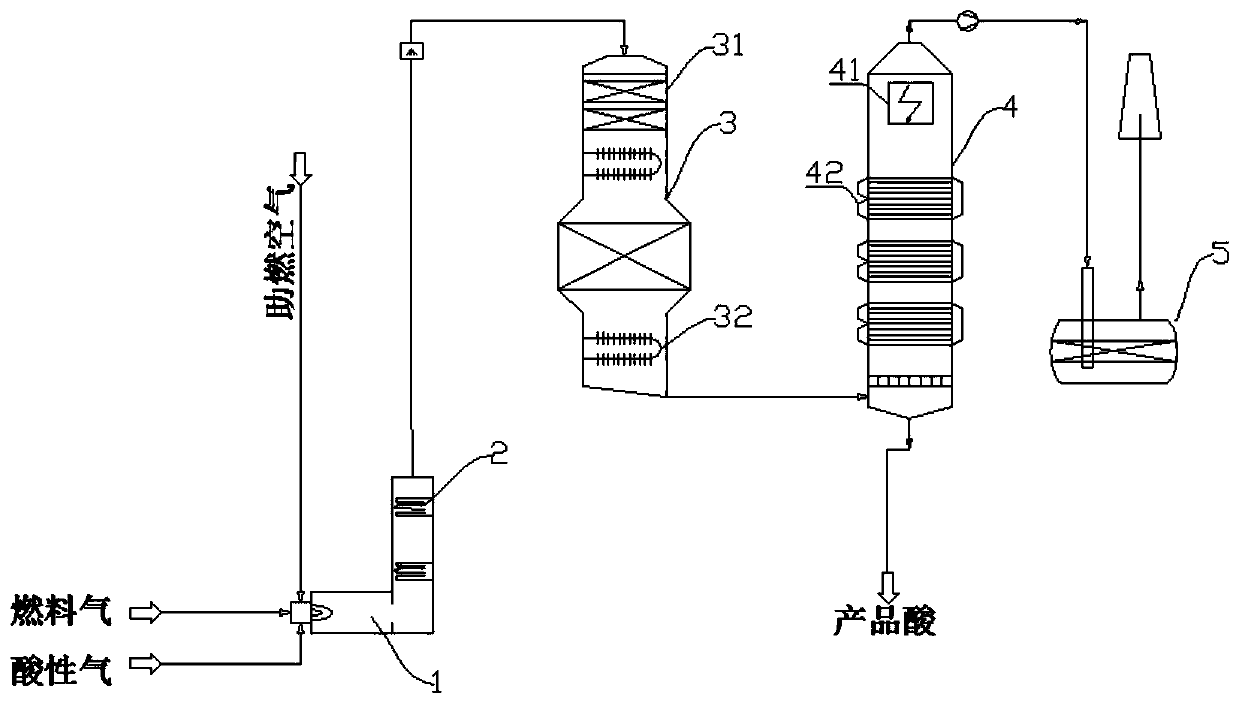

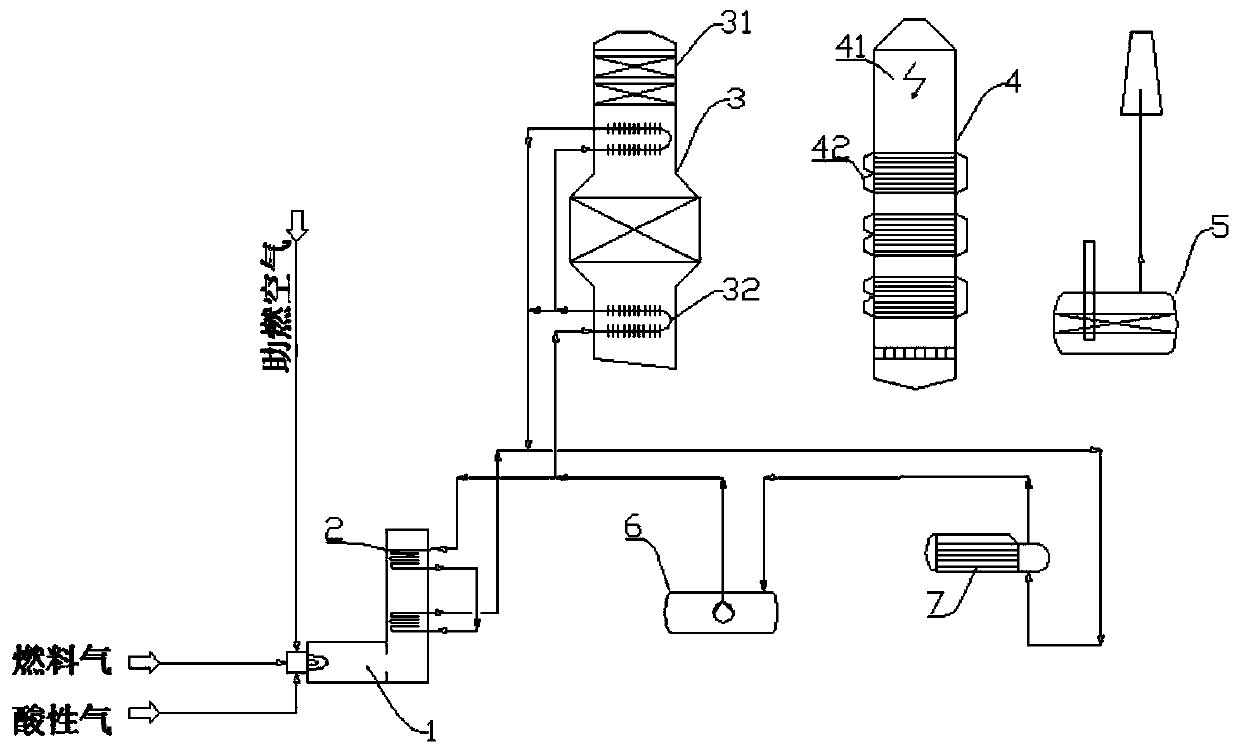

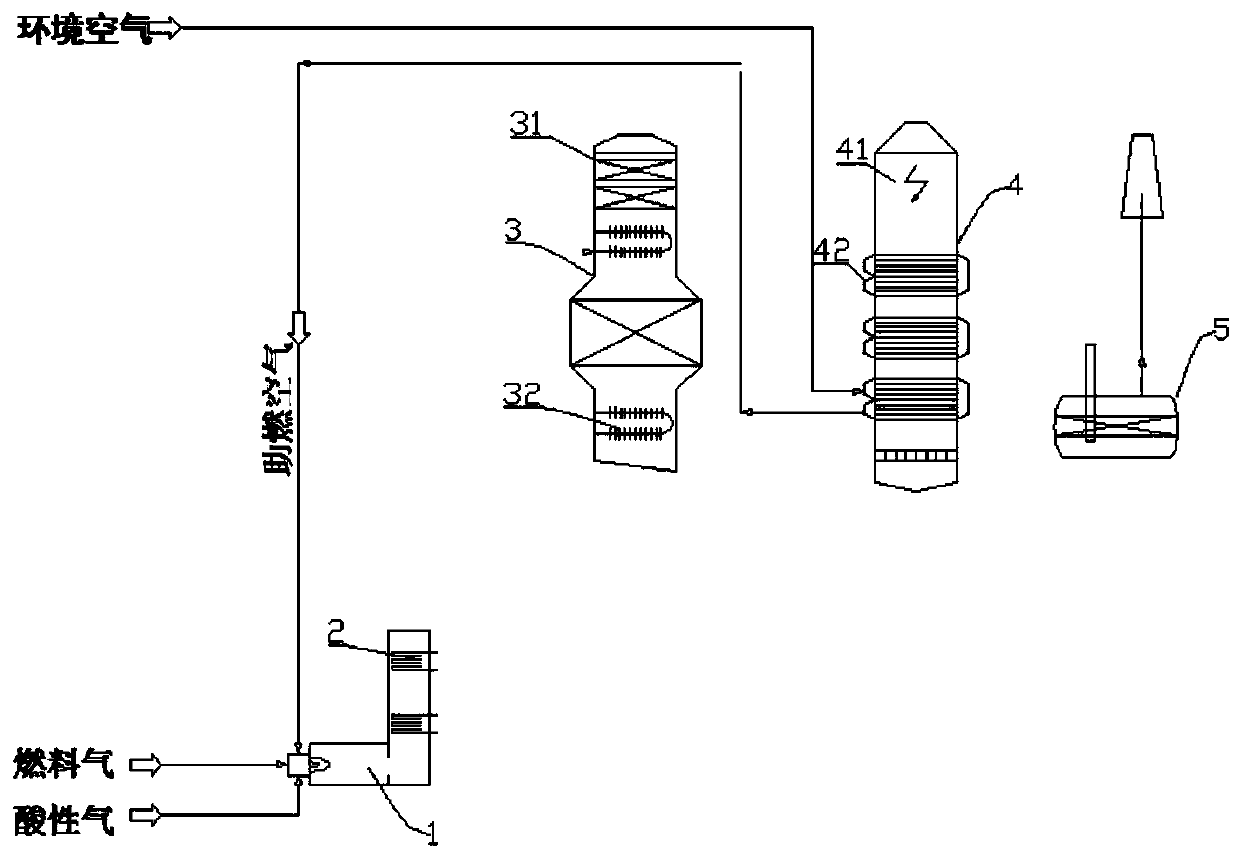

[0055] The scale of the device is 22,500 tons / year, and the raw material is 1354kg / h of refinery acid gas. The acid gas is combusted through the combustion furnace 1. The temperature of the combustion furnace is 1000°C and the pressure is 3Kpa(g). After heating to 230°C, send it to the combustion furnace. The temperature of the process gas at the outlet of the combustion furnace 1 is controlled at 440°C by the heat exchanger 2, and the hot process gas is sent to the reactor 3. The inlet pressure of the reactor 3 is 2.5KPa(g), the outlet pressure is -2KPa(g), and the outlet pressure Temperature 270°C, SO in reactor 3 2 Convert SO 3 The conversion rate was 98%.

[0056] The process gas at the outlet of reactor 3 enters the condenser 4, and the process gas is cooled to 256°C, 90°C, and 75°C through the glass tube heat exchanger from bottom to top, and the 2680kg / h high-concentration sulfuric acid is cooled in the glass tube heat exchanger shell The process is condensed and flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com