Cloud monitoring building material mould

A cloud monitoring and cloud monitoring system technology, applied in the direction of mold auxiliary parts, manufacturing tools, electrical components, etc., can solve the problems of poor mold accuracy, increased production costs and storage costs, and achieve the goal of reducing production errors and saving production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

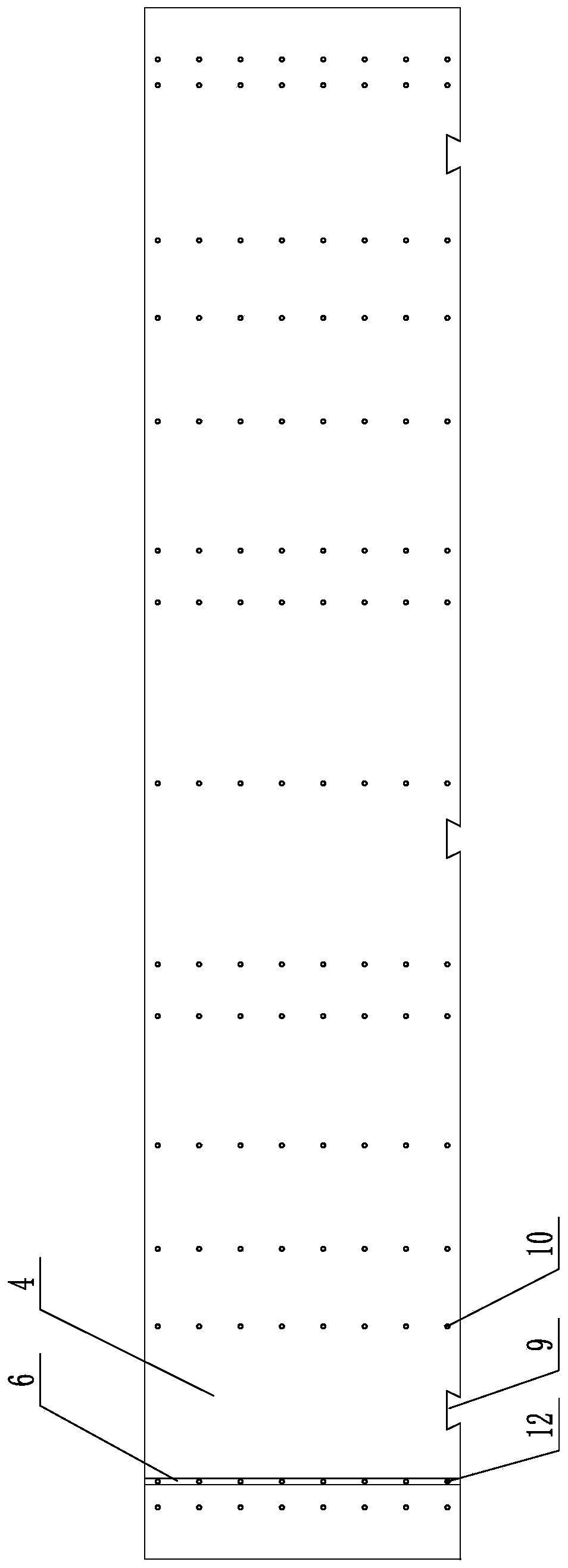

[0036]A cloud monitoring building material mold, including a base 1, the base is welded into a rectangular frame with I-shaped steel or C-shaped steel, and a leveling device 2 is arranged on the base 1. In this embodiment, the leveling device 2 includes a Several threaded holes on the base 1 and bolt feet matched with the threaded holes adjust the level of the base 1 by tightening and loosening the bolt feet in the threaded holes. A plurality of support beams 3 are welded on the top surface of the base 1, and a plurality of support beams 3 are linearly and parallelly arranged on the top surface of the base 1. The support beams are made of I-beams, and the two end surfaces of the I-beams are processed into Horizontal plane, and install the horizontal adjustment device 2 in its proper position. One end of the supporting beam is also welded with a reinforced diagonal brace, and the reinforced diagonal brace can support the baffle on one side of the edge. The top of the support b...

Embodiment 1

[0038] For embodiment 1, a bottom plate is welded or riveted to the lower side of the baffle plate in this embodiment, and the inner triangular pulley is fixed with screws on the floor, and the slide rail at the top of the support beam is a triangular raised guide rail fixed with screws, through which the inner triangular pulley and the The rolling friction of the triangular raised guide rail makes the movement of the baffle relative to the support beam more convenient and the frictional force is smaller under the condition that the guide rail limits the baffle.

Embodiment 3

[0040] Regarding embodiment 1, the cloud monitoring system in this embodiment includes a monitoring system, a server, and a wireless network communication module. The monitoring system is a cloud monitoring system developed by our company, and the reference document application number is CN201810542907.9. The monitoring system detects the working condition and working state of the hydraulic system through sensors, and the wireless network communication module transmits the installation location, working condition data, product appearance and actual production quantity of the equipment to the cloud server through the Internet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com