Cement-based stone-like curb stone as well as preparation method and molding equipment thereof

A technology of forming equipment and roadside stone, applied in the field of artificial stone, can solve the problems of reduced strength and performance, limited production amount, short service life, etc., and achieves the effect of reducing raw material cost, saving cost expenditure, and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0033] A cement-based imitation stone curbstone, including the following ingredients in weight percentage: 15% po42.5 cement, 27.5% fine yellow sand, 50% gypsum, 7.5% water, wherein the average particle size of fine yellow sand The diameter is 0.25mm-0.35mm, the fineness modulus is 2.2-1.6, and the gypsum is 0.1-10mm.

[0034] A preparation method of a cement-based imitation stone type curb, comprising the following steps:

[0035] a) Fully mix 15% po42.5 cement, 27.5% fine yellow sand, 50% gypsum, and 7.5% water to obtain concrete mixed wet material, in which the average particle size of yellow sand is 0.25mm-0.35 mm, fine yellow sand with a fineness modulus of 2.2-1.6, and a particle size of gypsum of 0.1-10mm;

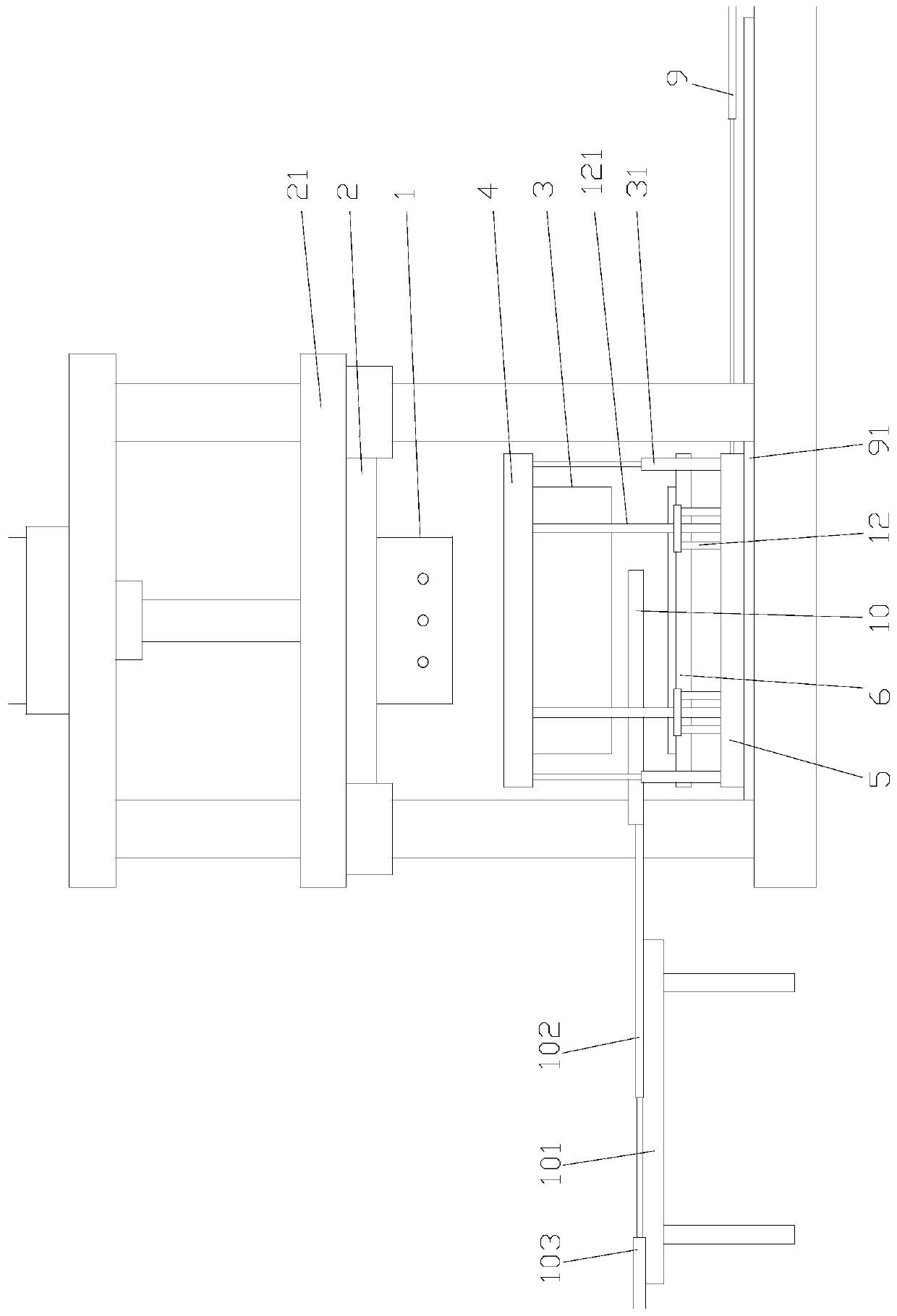

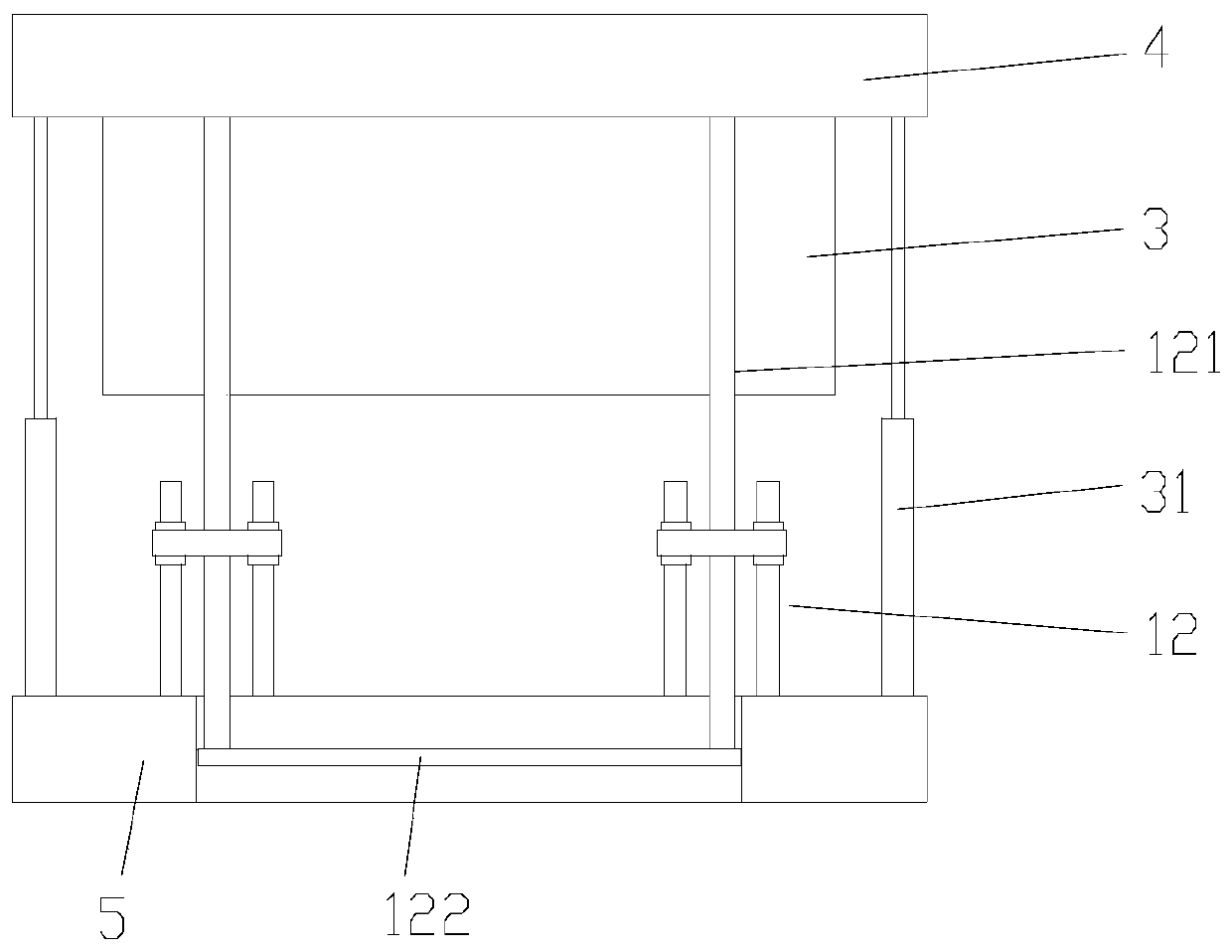

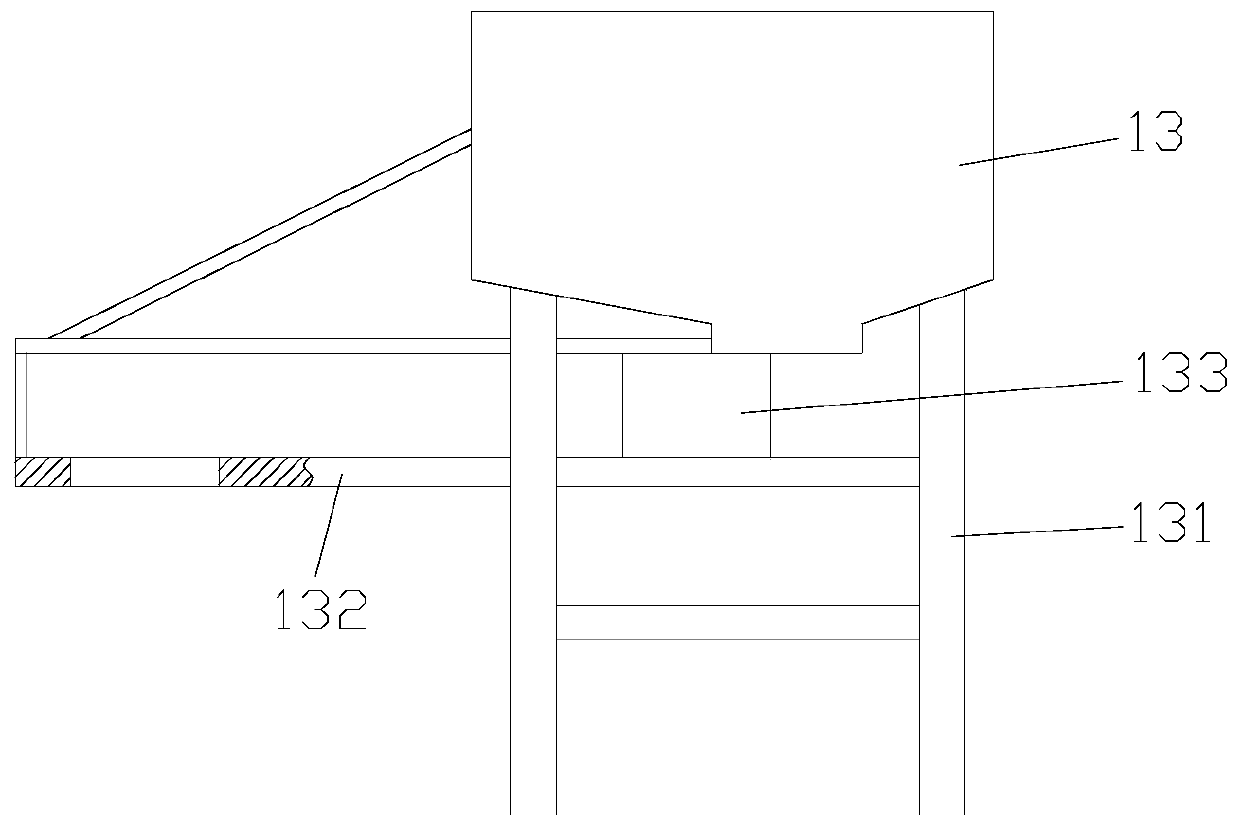

[0036] b) Quantitatively put the concrete mixed wet material into the mold cavity of the molding equipment, the molding equipment is closed, and the mold clamping pressure is controlled to 100MPa. The value is maintained at 1.0 MPa. Under normal temperature condit...

preparation Embodiment 2

[0041] A cement-based imitation stone curbstone, comprising the following components by weight percentage: 16% cement, 28% fine yellow sand with an average particle size of 0.25mm-0.35mm and a fineness modulus of 2.2-1.6, 50% % gypsum, 6% water.

[0042] A preparation method of a cement-based imitation stone type curb, comprising the following steps:

[0043] a) Fully mix 16% po42.5 cement, 28% fine yellow sand, 50% gypsum, and 6% water to obtain concrete mixed wet material, in which the average particle size of yellow sand is 0.25mm-0.35 mm, fine yellow sand with a fineness modulus of 2.2-1.6, and a particle size of gypsum of 0.1-10mm;

[0044] b) Quantitatively put the concrete mixed wet material into the mold cavity of the molding equipment, the molding equipment is closed, and the clamping pressure is controlled at 160MPa. At the same time as the mold is closed, the cavity is vacuumed from the bottom of the cavity, and the vacuum degree The value is maintained at 0.8 MPa...

preparation Embodiment 3

[0047] A cement-based imitation stone type curbstone, comprising the following ingredients in weight percentage: 14% cement, 26% fine yellow sand, 52% gypsum, 8% water, wherein the average particle size of fine yellow sand is 0.25 mm-0.35mm fine sand with a fineness modulus of 2.2-1.6.

[0048] A preparation method of a cement-based imitation stone type curb, comprising the following steps:

[0049] a) Fully mix 14% by weight po42.5 cement, 26% fine yellow sand, 52% gypsum, and 8% water to obtain concrete mixed wet material, in which the average particle size of yellow sand is 0.25mm-0.35 mm, fine yellow sand with a fineness modulus of 2.2-1.6, and a particle size of gypsum of 0.1-10mm;

[0050] b) Quantitatively put the concrete mixed wet material into the mold cavity of the molding equipment, the molding equipment is closed, and the clamping pressure is controlled at 120MPa. At the same time as the mold is closed, the cavity is vacuumed from the bottom of the cavity, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com