Far-infrared planar heat generator and production method thereof

A production method and heating element technology, applied in the field of far-infrared heating, can solve problems such as low resistance heating efficiency, high production cost, and human impact, and achieve the effects of quality assurance, production cost reduction, and damage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

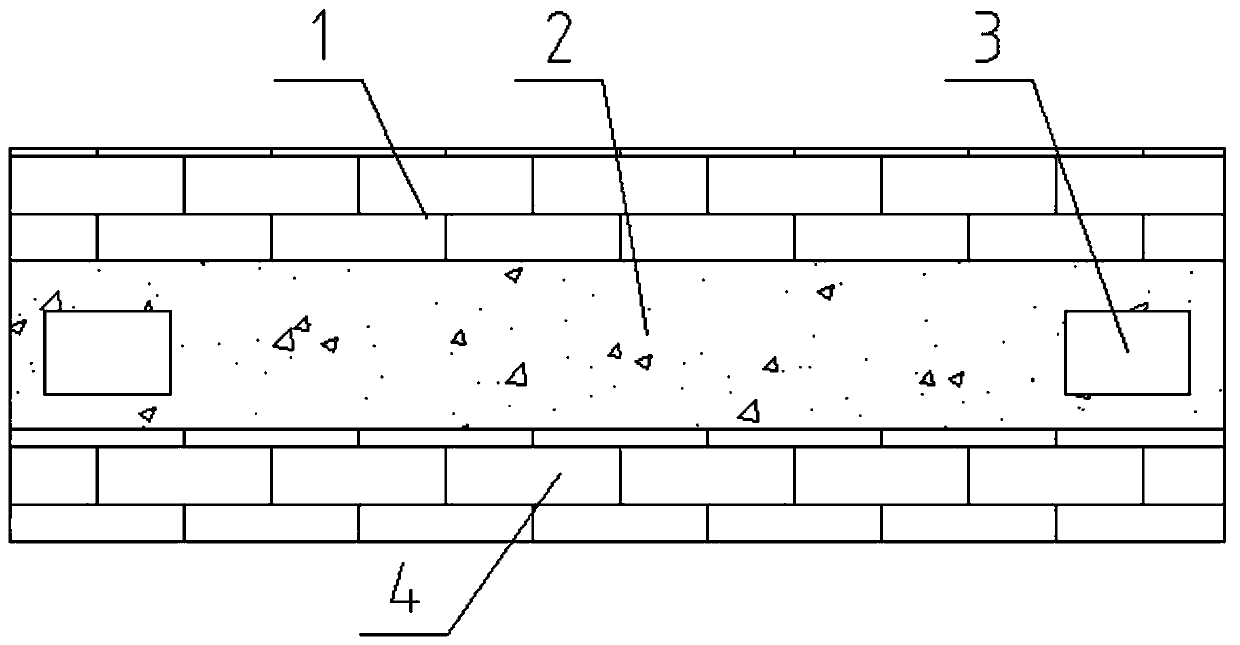

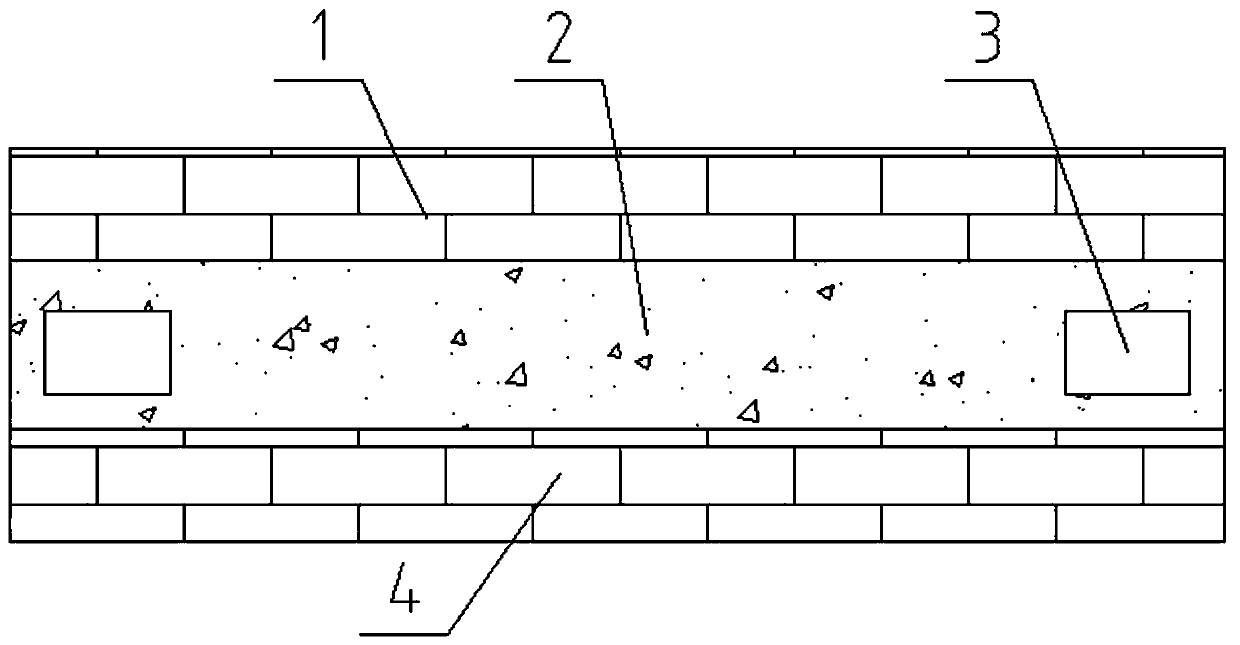

[0030] Such as figure 1 As shown, a far-infrared planar heating element, the heating element is a planar rectangular structure, including a heating substrate 2, an upper insulating heat conducting layer 1 arranged on the upper end of the heating substrate 2 and a lower layer arranged on the lower end of the heating substrate 2. As for the insulating and heat-conducting layer 4, the thickness of the heat-generating substrate 2 is 15-50 μm, the thickness of the upper insulating and heat-conducting layer 1 is 25 μm, and the thickness of the lower insulating and heat-conducting layer 4 is 25 μm. The horizontal ends of the heating substrate 2 are respectively provided with electrodes 3; the heating substrate 2, the upper insulating and heat-conducting layer 1 and the lower insulating and heat-conducting layer 4 are all flake structures, and the heating substrate 2 is made of graphene powder , nano-scale carbon powder and nano-scale PI powder are mixed at high temperature and then t...

Embodiment 2

[0041] This embodiment is improved on the basis of Embodiment 1, and further includes the following steps: S7: Coating heat-insulating material on one side of the formed planar heating element, and forming unidirectional radiation by providing heat-insulating material on one side of the heating element , can conveniently control the radiation direction of the heating element, and the heat insulating material is a modified polymer material.

[0042] All the other structures and preparation method of embodiment 2 are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com