Cable sealing clamping and shielding woven layer compaction one-key tail clamp

A cable sealing and cable shielding technology, which is applied in the direction of connection, parts of connecting devices, devices for reducing the stress at the connection of wires, etc. , to achieve the effect of improving assembly efficiency, shortening assembly time and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

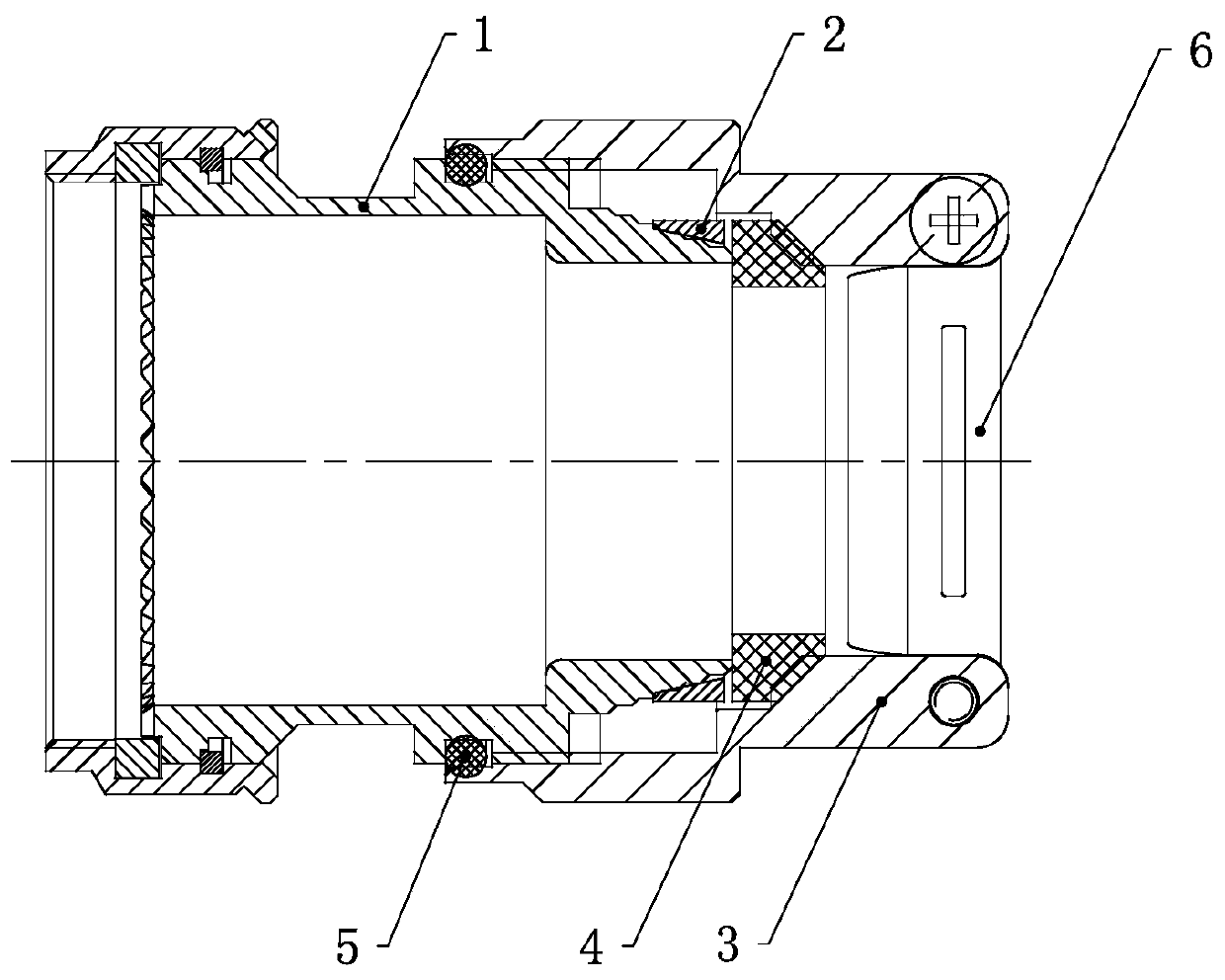

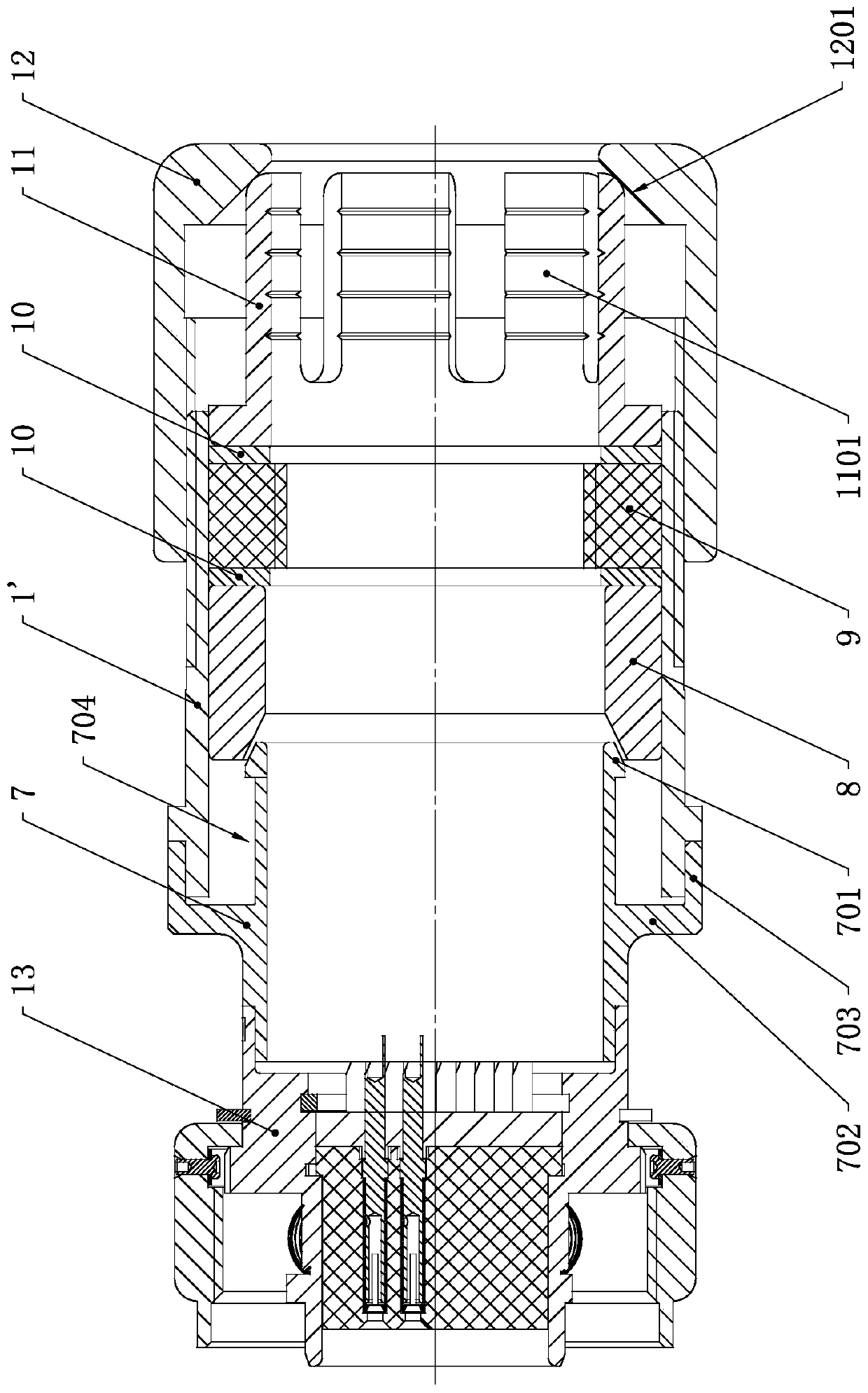

[0034] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments. In this embodiment, the position where the connector housing 13 is located is defined as "front", and the position where the tail clip nut 12 is located is defined as "rear".

[0035] see image 3 , based on the working environment requirements of high temperature, high radiation, and high sealing performance, the present invention proposes a cable sealing, cable clamping, and cable shield braiding layer pressing one-key realization type connector tail clamp, including sleeve 1', transfer welding Cylinder 7, shielding ring 8, rubber ring 9, gasket 10, clamping ring 11 and tail clip nut 12.

[0036] Sleeve 1' is used as the end clamp housing, which is used to assemble the transfer welding cylinder, shielding ring, rubber ring, clamping ring and end clamp nut distributed in sequence along the axial direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com