Material dynamic damage evolution experiment method of high temporal-spatial resolution

A technology of dynamic damage evolution and spatio-temporal resolution, which is applied to the analysis of materials, the use of one-time impact force to test the strength of materials, measuring devices, etc., can solve the problems of low spatio-temporal resolution, single, fuzzy damage distribution information, etc. The effect of high efficiency, convenient experiment implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] As shown in the figure, an experimental method for dynamic damage evolution of materials with high temporal and spatial resolution includes the following specific steps:

[0019] (1) Take a conical sample 1 in the shape of a cone and fix it, and then place multiple speed measuring probes 2 in the all-fiber laser interference velocimeter (not shown in the figure) in sequence along the direction of the conical surface of the conical sample 1. Fix and make the velocity measuring probe 2 perpendicular to the conical surface of the conical sample 1;

[0020] (2) Control the flying piece 3 to hit the big end face of the conical sample 1;

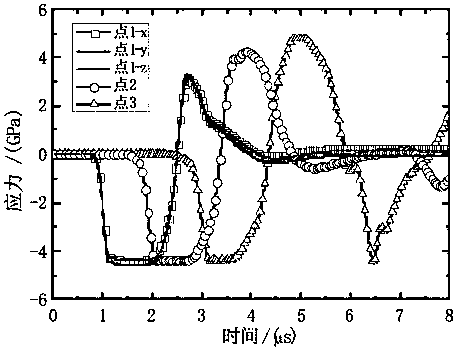

[0021] (3) After the impact, a shock compression wave is generated to the flyer 3 and the large head surface of the conical sample 1 respectively, that is, the shock compression wave 3-1 of the flyer and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com