Engine thermal baffle installation nut and automobile

A heat shield and engine technology, which is applied to nuts, pipes protected by heat insulation, thin plate connections, etc., can solve the problems of affecting assembly stability, nut features, relatively high installation environment requirements, and abnormal noise of heat shields, etc., to achieve installation Robust, adaptable, and reliability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

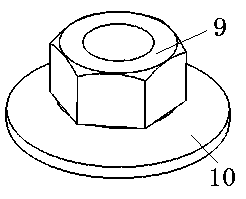

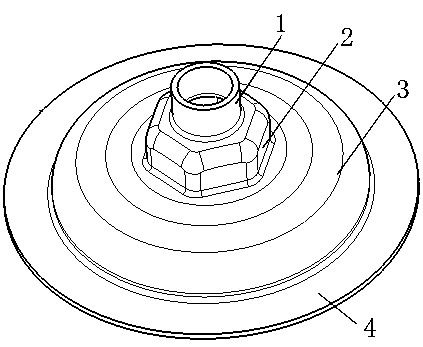

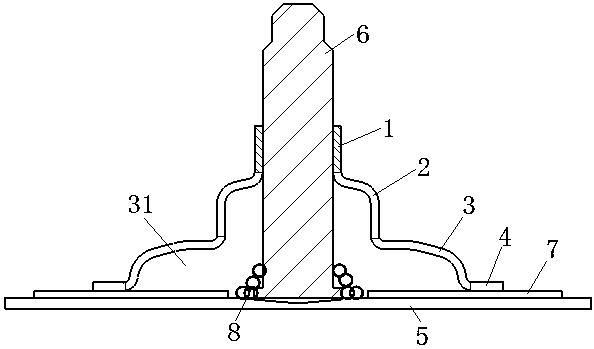

[0016] see figure 1 and figure 2 , the mounting nut for the engine heat shield shown is formed by integral stamping of steel, including a cylindrical nut body 1 with threads on the inner wall, a boss 2 at one end of the nut body 1, and a boss 2 on the boss 2 For the clamping surface of the tightening tool, a transition section 3 whose radial dimension gradually increases is provided at the free end of the boss 2, and an avoidance chamber 31 is provided in the transition section 3, and a transition section 3 is provided at the free end of the transition section 3. There is a pressing plate 4 extending outward.

[0017] The outer peripheral surface of the boss 2 is provided with six action surfaces, and arc surfaces are respectively arranged at both ends of every two action surfaces in the circumferential direction of the boss 2 . According to the layout space or i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com