Locknut and application method thereof

A technology for locking nuts and nut bodies, applied in the directions of nuts, screws, bolts, etc., can solve the problems of lengthening bolts or threaded shafts, increasing the space occupied by bolts or threaded shafts, increasing costs, etc., to achieve cost savings and a wide range of applications. , the effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

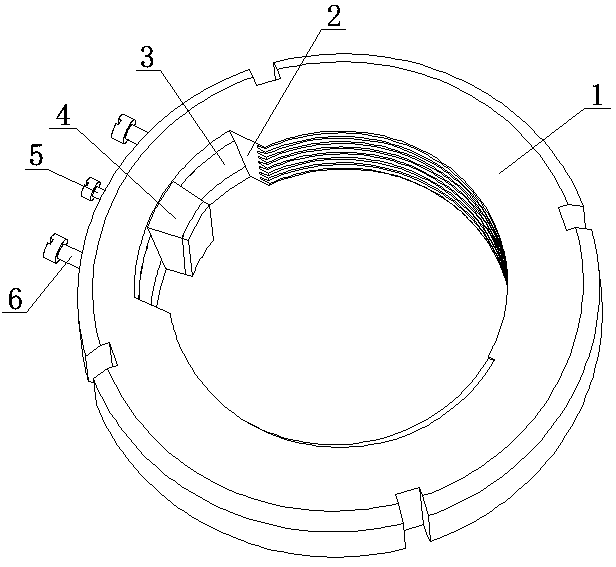

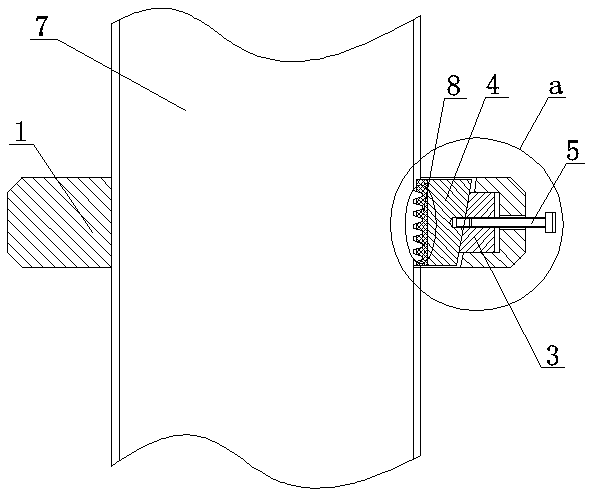

[0025] Example: such as Figure 1 to Figure 5 As shown, a lock nut includes a nut body 1 threadedly connected with a threaded shaft 7 . The nut body 1 is provided with internal threads matching the threaded shaft 7 . A wedge groove 2 is provided on the side of the nut body 1 close to the threaded shaft 7 . The transverse section of the wedge groove 2 is arc-shaped. A wedge 4 is arranged in the wedge groove 2 . A pressing block groove 9 is provided on the side of the wedge groove 2 facing the threaded shaft 7 . The opening of the briquetting groove 9 faces the threaded shaft 7. A pressing block 3 that can move radially along the nut body 1 is arranged in the pressing block groove 9 . The briquetting block 3 is matched with the briquetting block groove 9 . The transverse section of the pressing block 3 is arc-shaped. One side of the wedge 4 close to the threaded shaft 7 fits with the external thread on the threaded shaft 7 , and the other side of the wedge 4 fits with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com