Method for preventing liquid rocket engine injector panel from being ablated by high-temperature fuel gas

A liquid rocket and engine technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve problems such as small synthetic momentum angle, backflow and ablation of gas in the border area, and achieve strong applicability and eliminate excessive heat load , Good effect of technology expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

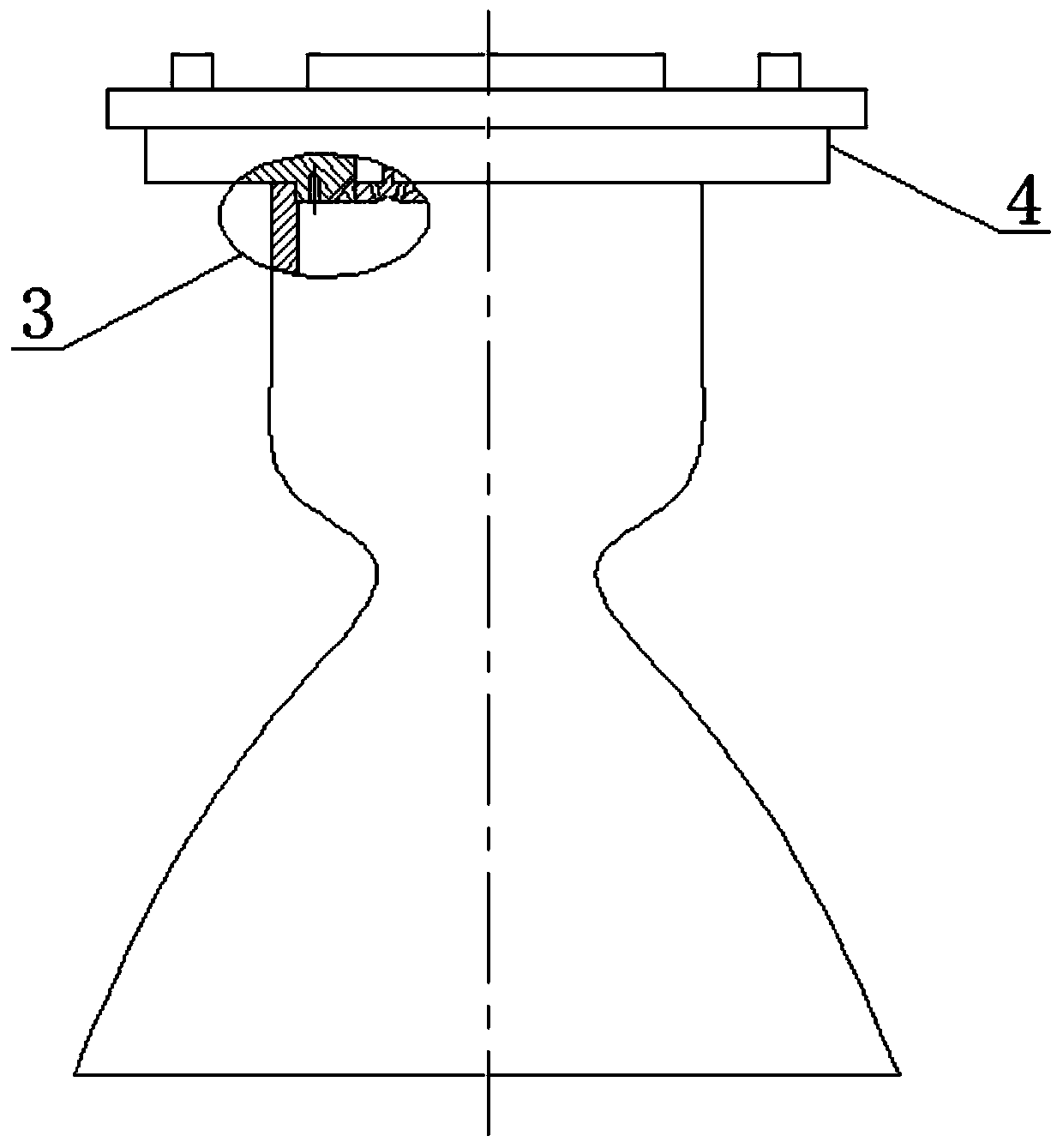

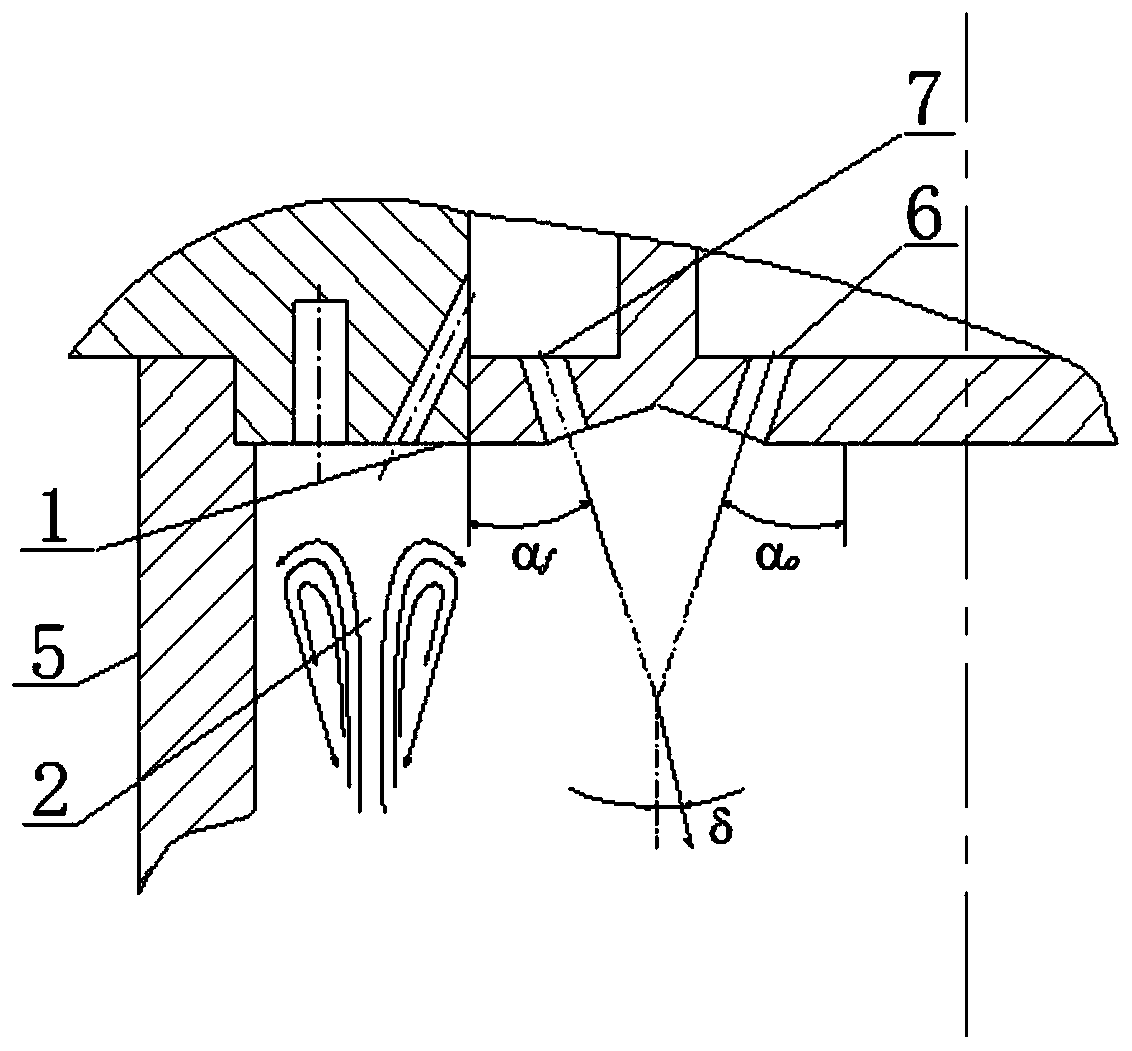

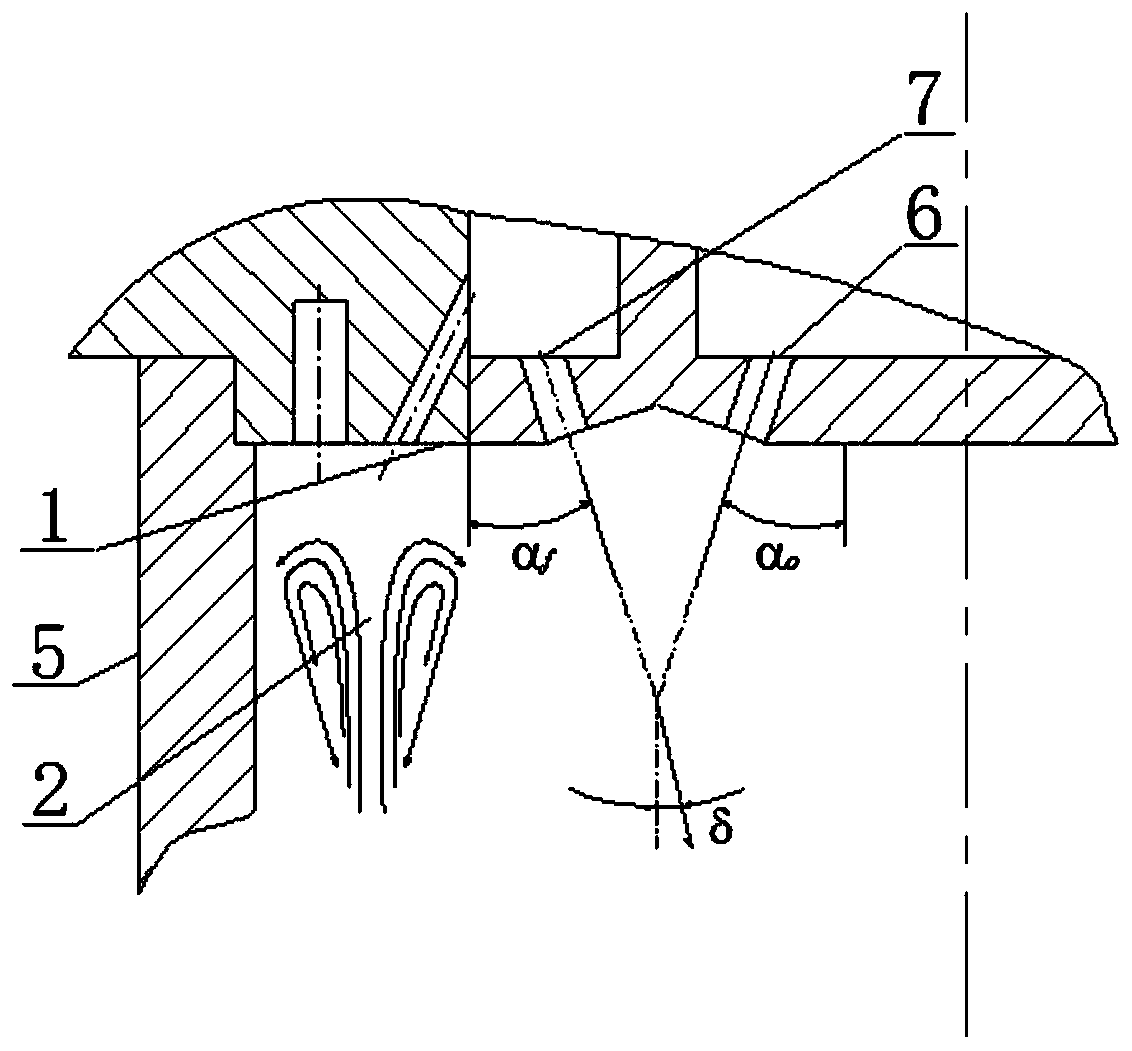

[0023] Specific implementation mode one: see Figure 1-Figure 2 This embodiment will be described. A method for preventing liquid rocket engine injector panels from being ablated by high-temperature gas described in this embodiment, the mixing ratio of engine fuel and oxidant is r m , the r m ≥1.45. Part of the oxidant and fuel are injected from the outermost oxidant nozzle 6 and the fuel nozzle 7 respectively, and the deflection angle of the outermost oxidant nozzle 6 is α o , the α o =45°, the deflection angle of the fuel nozzle 7 is α f , the α f = 40°, the two jets collide below the injector panel 1 to form a high-temperature gas backflow 2, the high-temperature gas backflow 2 is close to the inner wall of the combustion chamber 5, and the combined momentum angle formed after the two jets collide is δ, and the The control value of δ is 8°~18°. The high-temperature gas backflow 2 is closely related to the resultant momentum angle δ.

[0024] Fuel and oxidizer at nom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com