Combined type connected bamboo-concrete combined beam and manufacturing method

A concrete and combined technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of difficult to achieve complete rigid connection between bamboo and concrete, difficult for metal parts to play a role, complicated construction, etc., to achieve easy standardized production, use of steel The effect of small volume and large connection contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

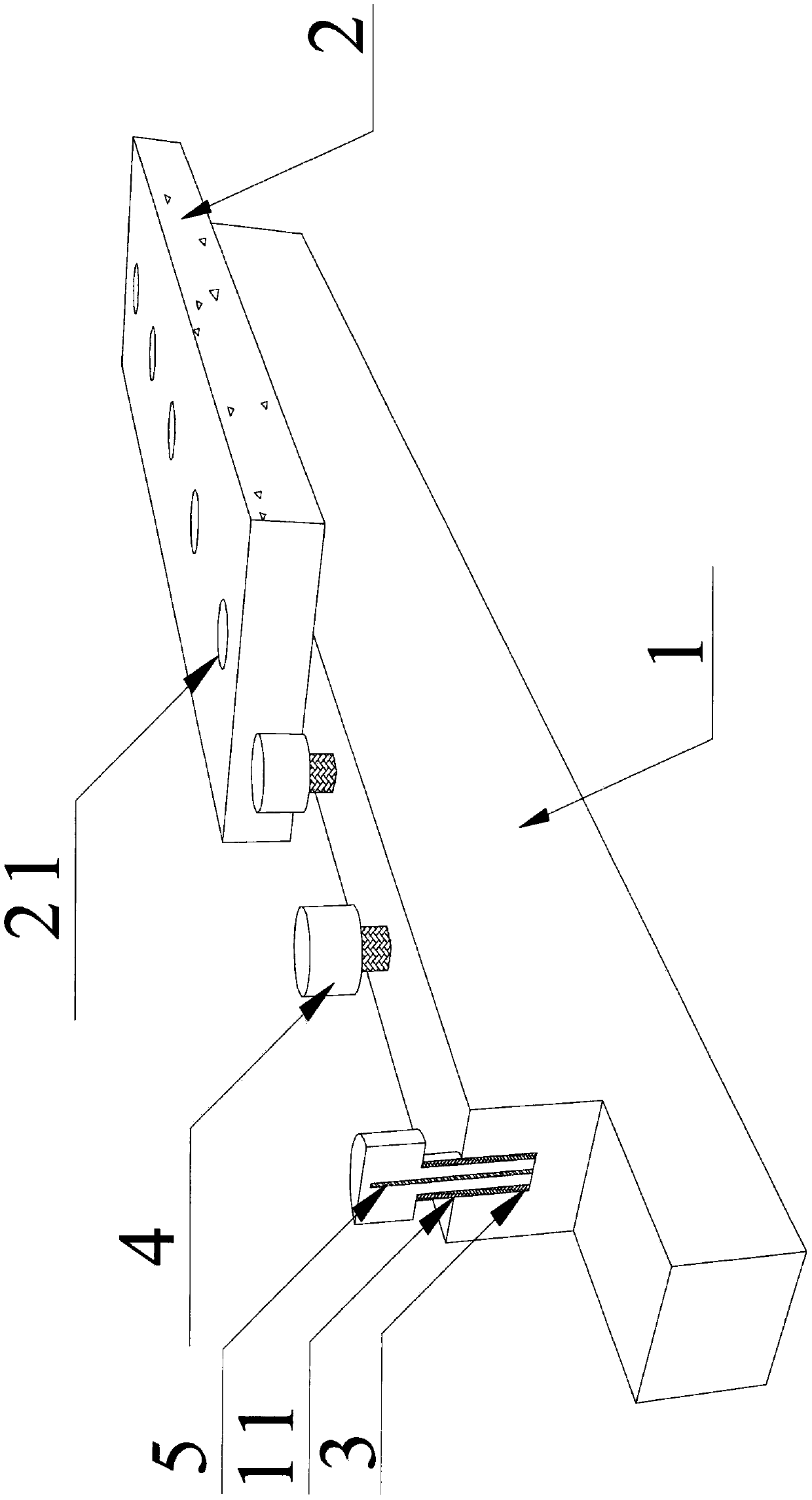

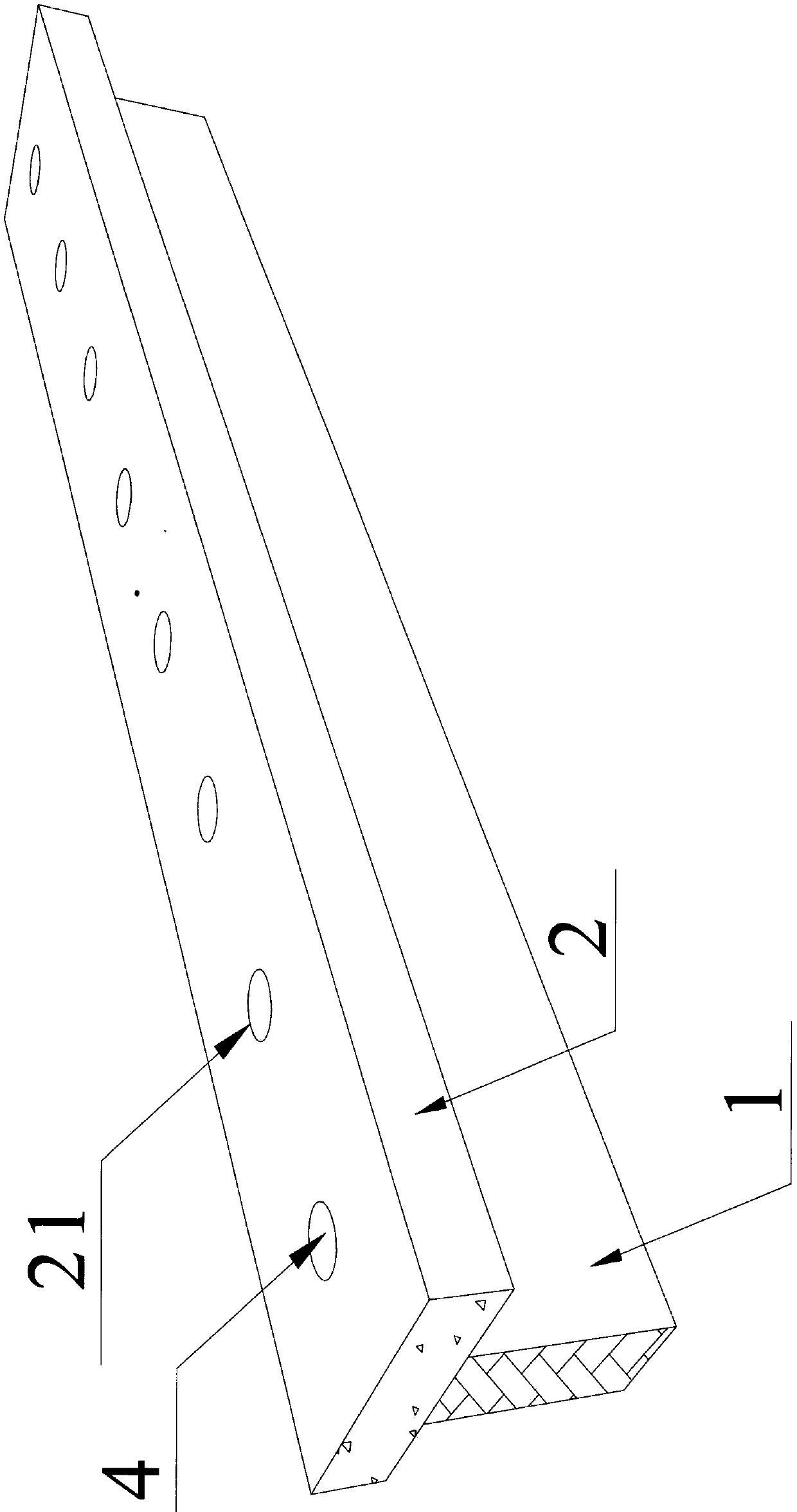

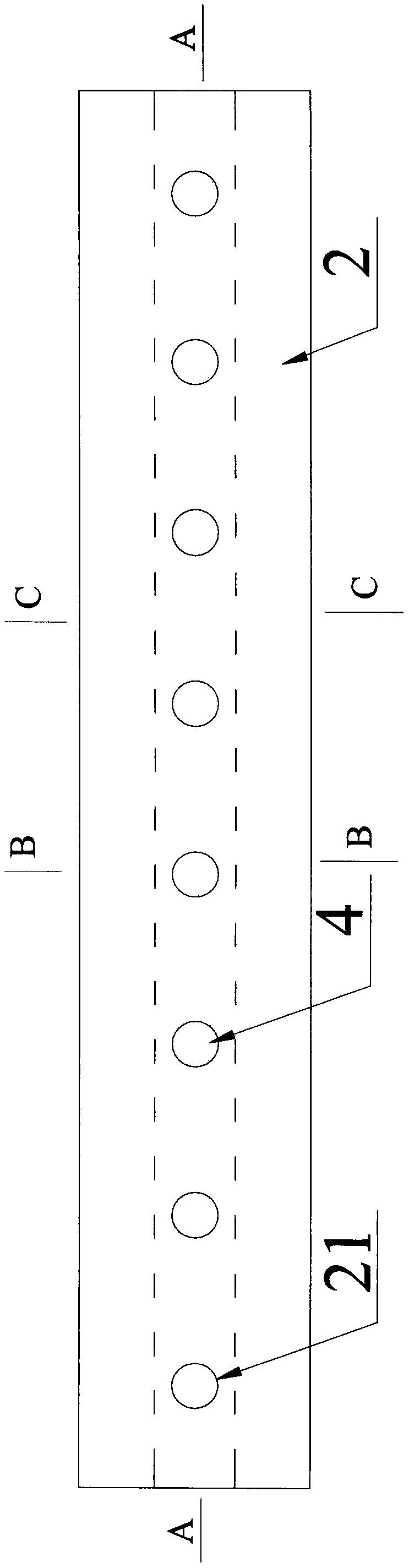

[0042] In order to have a clearer understanding of the technology, features, purposes and effects of the present invention, specific implementations of the present invention will now be described with reference to the accompanying drawings.

[0043]As shown in the accompanying drawings, the present invention provides a combined bamboo-concrete composite beam, which is characterized in that it comprises a bamboo beam 1, a concrete slab 2, a bamboo tube 3, a high-strength filling material 4, and a reinforcing rib 5, and the concrete slab 2 is located on the bamboo beam. 1, the top surface of the bamboo beam 1 is provided with a number of bamboo holes at intervals, the diameter of the bamboo holes is equal to the outer diameter of the bamboo tube 3, and the outer surface of the middle and lower part of the bamboo tube 3 is bonded and fixed in the bamboo hole by applying an adhesive. Inside, the position of the bamboo hole corresponding to the concrete slab 2 and the bamboo beam 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com