Diaphragm wall construction method

A technology of underground diaphragm wall and construction method, which is applied in sheet pile wall, foundation structure engineering, earth mover/shovel, etc., can solve the problems of exposed reinforcement quality defect of steel cage, poor concrete fluidity, exposed steel cage, etc. Achieve the effect of increasing the range of vibration, uniform distribution of concrete, and enhanced fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] A method for constructing an underground diaphragm wall, comprising the steps of:

[0013] 1), forming a groove;

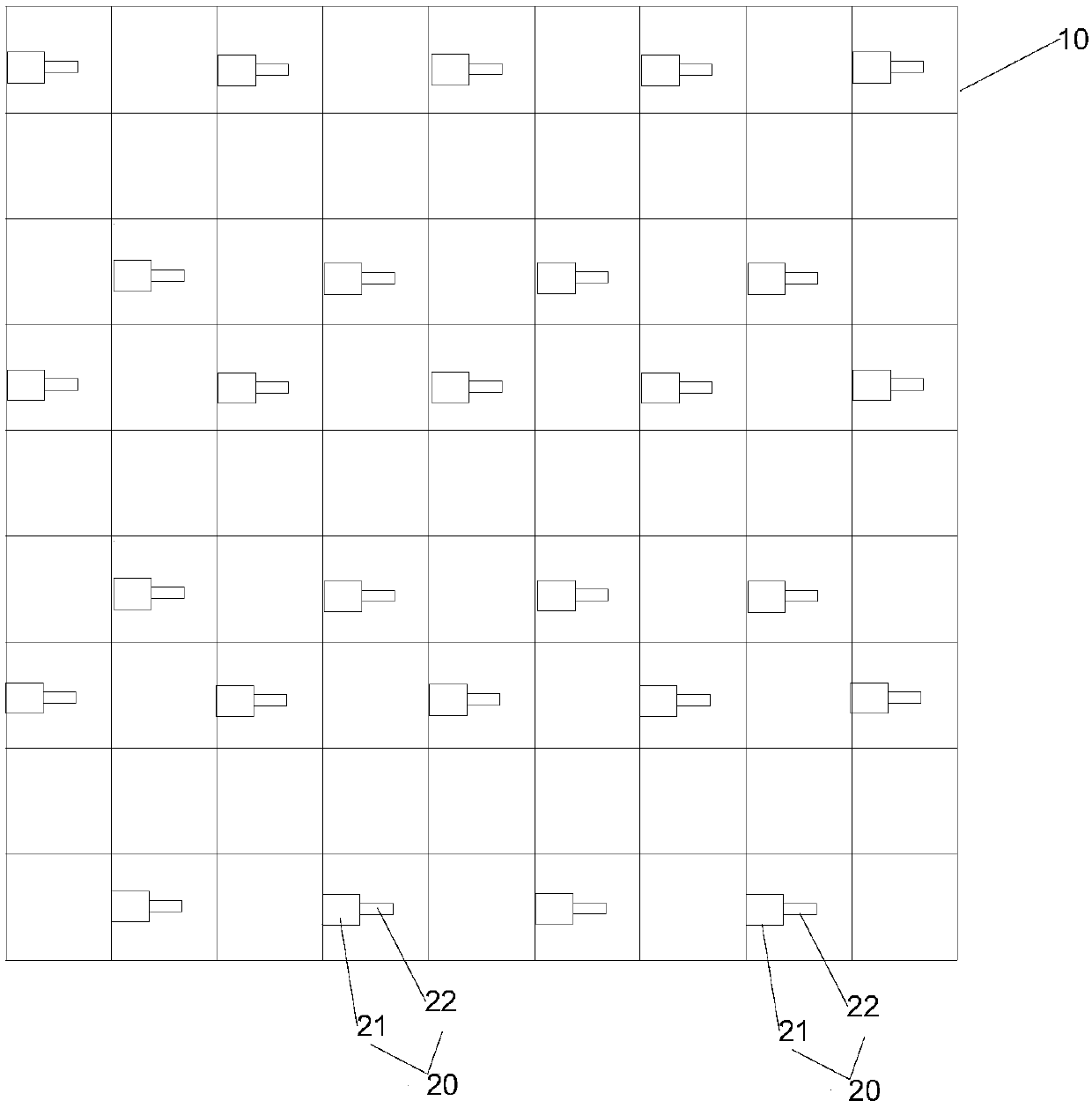

[0014] 2), hoisting reinforcement cage; such as figure 1 Shown is a structural schematic diagram of the reinforcement cage used in the present invention, and a plurality of vibrating devices 20 are arranged on the reinforcement cage 10 . Each vibrating device 20 includes a motor 21 and a vibrating rod 22 . The motor 21 drives the vibrating rod 22 to vibrate. The vibrating rod 22 protrudes from the steel cage 10 .

[0015] 3) Concrete is poured. During the pouring process, the vibrating device is used to exert force on the concrete to increase the flow of the concrete and form a wall.

[0016] The construction method of the underground diaphragm wall in the present invention exerts force on the concrete during the pouring process, enhances its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com