A preparation method of long-life iridium-zirconium composite oxide inert anode

A composite oxide, inert anode technology, applied in electrodes, liquid chemical plating, coatings, etc., can solve the problems of limited large-scale application, short anode life, high anode production cost, easy operation and equipment investment. Low, less equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

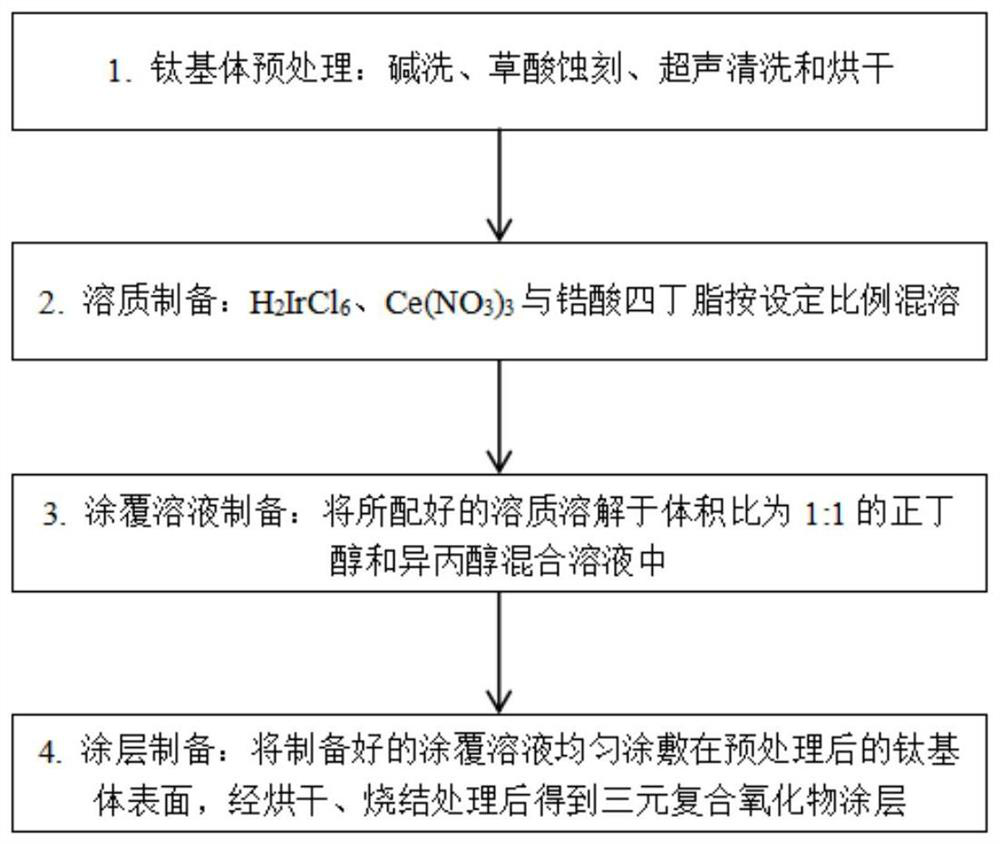

Embodiment approach 1

[0039] First, a titanium plate of 10mm×10mm×1mm was washed with alkali at 60°C for 30 minutes, etched with 10% oxalic acid at 90°C for 2.5 hours, ultrasonically cleaned with deionized water for 10 minutes, and then dried for use.

[0040] Weigh a certain mass of Ce(NO 3 ) 3 、H 2 IrCl 6 Miscible with tetrabutyl zirconate.

[0041] The miscible Ce(NO 3 ) 3 、H 2 IrCl 6 The mixed solution of tetrabutyl zirconate and tetrabutyl zirconate is dissolved in a mixed solvent of n-butanol and isopropanol mixed in a ratio of 1:1 to obtain a coating solution. Ce(NO 3 ) 3 、H 2 IrCl 6 The molar concentrations of tetrabutyl zirconate and tetrabutyl zirconate were 0.098, 0.042 and 0.060 mol / L, respectively.

[0042] The prepared coating solution was evenly coated on the surface of the pretreated titanium substrate with a brush, dried at 120°C for 10 minutes, then sintered at 500°C for 10 minutes, and cooled to room temperature after taking it out. After the above steps were repeate...

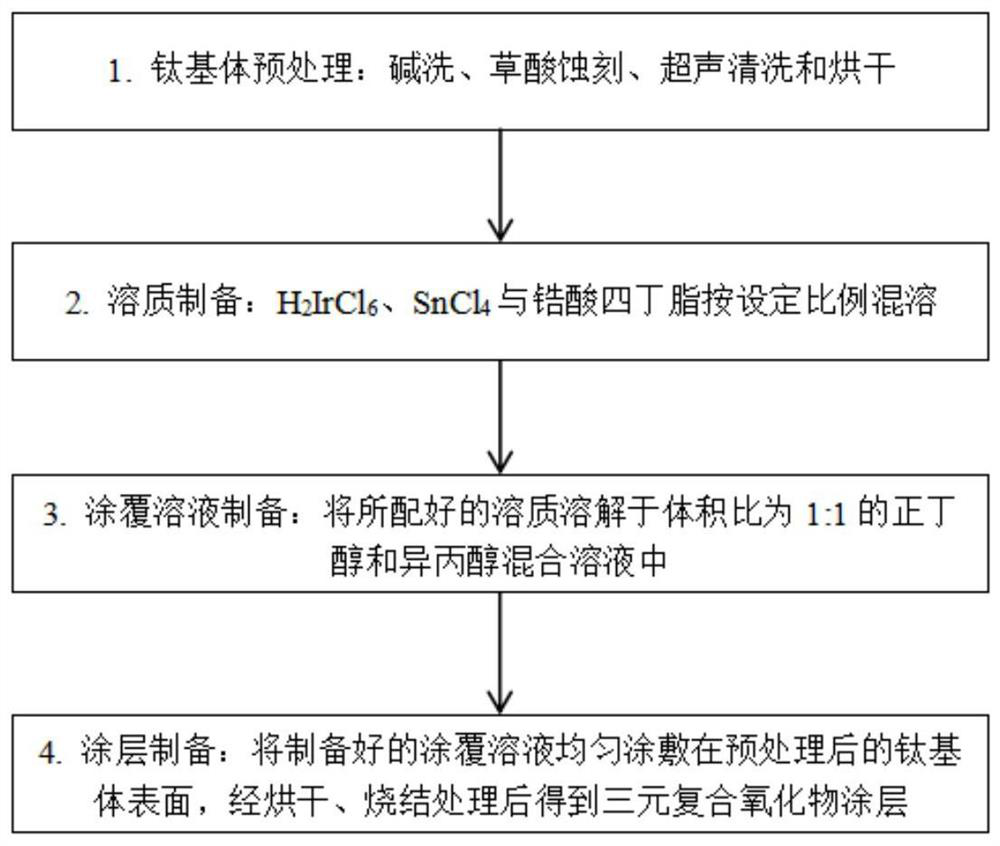

Embodiment approach 2

[0045] First, a titanium plate of 10mm×10mm×1mm was washed with alkali at 60°C for 30 minutes, etched with 10% oxalic acid at 90°C for 2.5 hours, ultrasonically cleaned with deionized water for 10 minutes, and then dried for later use.

[0046] Weigh a certain mass of Ce(NO 3 ) 3 、H 2 IrCl 6 Miscible with tetrabutyl zirconate.

[0047] Ce(NO 3 ) 3 、H 2 IrCl 6 The mixed solution with tetrabutyl zirconate is dissolved in a mixed solvent of n-butanol and isopropanol mixed in a ratio of 1:1 to obtain a coating solution. Ce(NO 3 ) 3 、H 2 IrCl 6 The molar concentrations of tetrabutyl zirconate and tetrabutyl zirconate were 0.050, 0.050 and 0.100 mol / L, respectively. .

[0048] The prepared coating solution was evenly coated on the surface of the pretreated titanium substrate with a brush, dried at 120°C for 15 minutes, then sintered at 450°C for 15 minutes, and cooled to room temperature after taking it out. After the above steps were repeated 25 times, the anode plate...

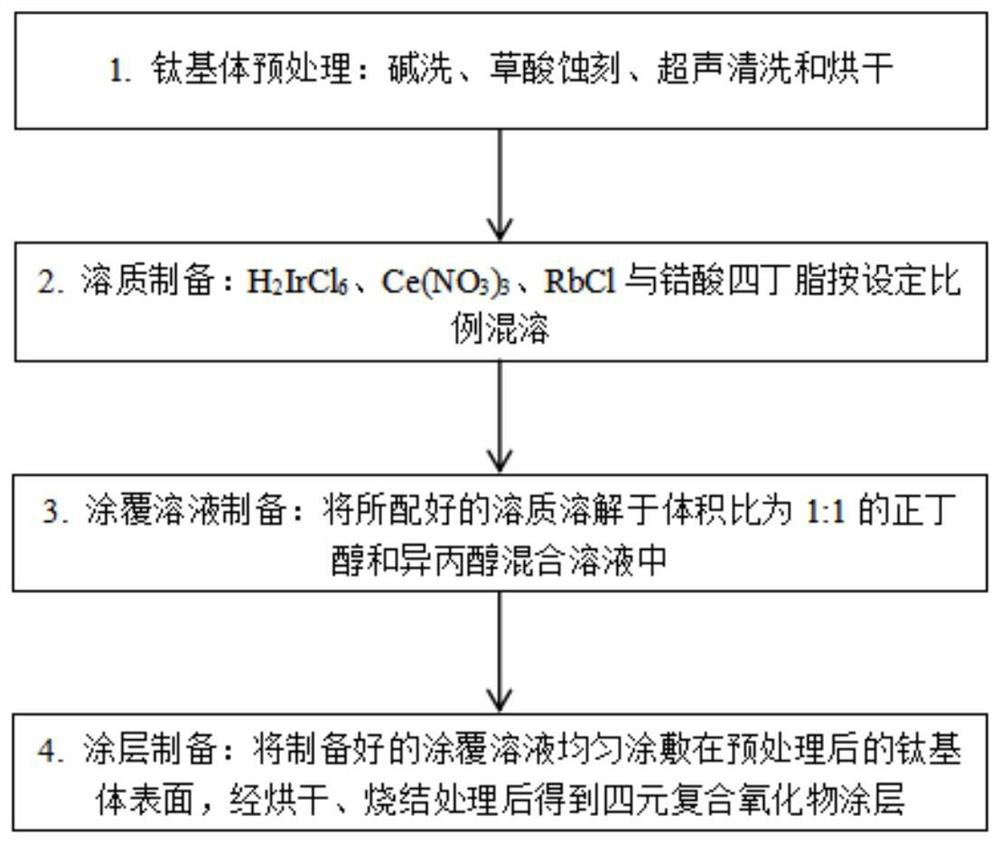

Embodiment approach 3

[0051] First, a titanium plate of 10mm×10mm×1mm was washed with alkali at 60°C for 30 minutes, etched with 10% oxalic acid at 90°C for 2.5 hours, ultrasonically cleaned with deionized water for 10 minutes, and then dried for later use.

[0052] Weigh a certain mass of Ce(NO 3 ) 3 、H 2 IrCl 6 Miscible with tetrabutyl zirconate.

[0053] Ce(NO 3 ) 3 、H 2 IrCl 6 The mixed solution with tetrabutyl zirconate is dissolved in a mixed solvent of n-butanol and isopropanol mixed in a ratio of 1:1 to obtain a coating solution. Ce(NO 3 ) 3 、H 2 IrCl 6 The molar concentrations of zirconate and tetrabutyl zirconate were 0.042, 0.098 and 0.060mol / L, respectively.

[0054] The prepared coating solution was evenly coated on the surface of the pretreated titanium substrate with a brush, dried at 120°C for 15 minutes, then sintered at 400°C for 15 minutes, and cooled to room temperature after taking it out. After the above steps were repeated 25 times, the anode plate was sintered a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com