Plastic bag capable of being quickly naturally degraded

A plastic bag, fast technology, applied in the field of plastics, can solve the problems of unfavorable crop growth, plastic bag soil compaction, secondary pollution, etc., and achieve the effect of improving ion exchange capacity, fast hydrolysis speed, and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

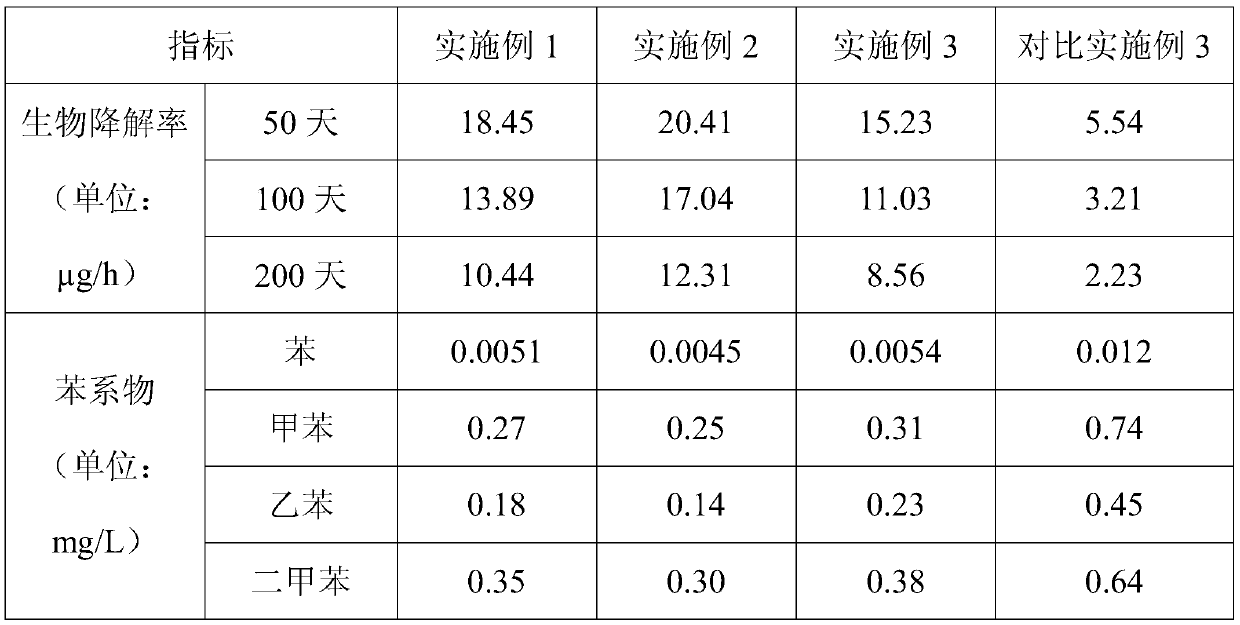

Embodiment 1

[0052] A rapidly and naturally degradable plastic bag, the plastic bag material includes the following components in parts by weight:

[0053] 35 parts of carboxy-modified polyvinyl alcohol;

[0054] 22.5 parts of modified starch;

[0055] 17.5 parts of waste plant fiber;

[0056] 10 parts of polyacrylamide;

[0057] 12.45 parts of polyaluminum chloride;

[0058] 35.05 parts of sulfonated bisphenol-based polyaryl ether sulfone;

[0059] 12.5 parts of nano-immobilized laccase catalyst;

[0060] 8.5 copies of Pseudomonas and Nocardia were embedded in nano-microcapsules;

[0061] 7.5 parts of EDTA.

[0062] Wherein, the preparation method of nano-immobilized laccase comprises the following steps:

[0063] S1: Dissolve nanoscale laccase in distilled water for 1.5 hours at 24.5°C;

[0064] S2: Pass the mixture obtained in step S1 through a 0.235 μm sterile filter to obtain a laccase catalyst with 7000 U / L enzyme activity;

[0065] S3: 5g of mesoporous silica particles were...

Embodiment 2

[0085] A rapidly and naturally degradable plastic bag, the plastic bag material includes the following components in parts by weight:

[0086] 40 parts of carboxy-modified polyvinyl alcohol;

[0087] 25 parts of modified starch;

[0088] 20 parts of waste plant fiber;

[0089] 12 parts of polyacrylamide;

[0090] 15 parts of polyaluminum chloride;

[0091] 40 parts of sulfonated bisphenol-based polyaryl ether sulfone;

[0092] 15 parts of nano-immobilized lignin peroxidase catalyst;

[0093] 10 copies of Flavobacteria embedded in nano-microcapsules;

[0094] EDTA 10 parts.

[0095] Wherein, the preparation method of nano immobilized lignin peroxidase comprises the following steps:

[0096] S1: dissolving nanoscale lignin peroxidase in distilled water at 26°C for 2 hours;

[0097] S2: Pass the mixture obtained in the S1 step through a 0.25 μm sterile filter membrane to obtain a lignin peroxidase catalyst with 9000U / L enzyme activity;

[0098] S3: 6g of mesoporous silic...

Embodiment 3

[0118] A rapidly and naturally degradable plastic bag, the plastic bag material includes the following components in parts by weight:

[0119] 30 parts of carboxy-modified polyvinyl alcohol;

[0120] 20 parts of modified starch;

[0121] 15 parts of waste plant fiber;

[0122] 8 parts of polyacrylamide;

[0123] 10 parts of polyaluminum chloride;

[0124] 30 parts of sulfonated bisphenol-based polyaryl ether sulfone;

[0125] 10 parts of nano-immobilized manganese peroxidase catalyst;

[0126] Nano-microcapsules embed 7 copies of Pallidum bacillus;

[0127] EDTA 5 parts.

[0128] Wherein, the preparation method of nano-immobilized manganese peroxidase comprises the following steps:

[0129] S1: Dissolve nanoscale manganese peroxidase in distilled water for 1 hour at 23°C;

[0130] S2: Pass the mixture obtained in the S1 step through a 0.22 μm sterile filter to obtain a manganese peroxidase catalyst with 5000U / L enzyme activity;

[0131] S3: Put 4 g of mesoporous silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com