A kind of starch-based scale inhibitor and its preparation method and application

A kind of antiscalant and starch-based technology, which is applied in the field of starch-based antiscalant and its preparation, can solve the problems of poor antiscaling effect and achieve good circulation, broad application prospects and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the starch-based scale inhibitor of the present embodiment, the steps are specifically:

[0028] 1. Material preparation

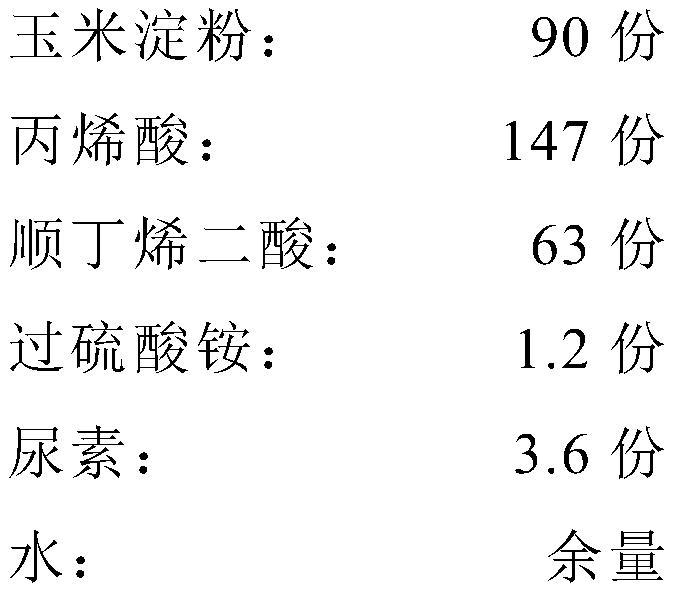

[0029] Calculated by producing 1000 mass parts of antiscalants, the amount of each ingredient (mass parts) is as follows:

[0030]

[0031] According to the above-mentioned preparation amount, the cornstarch is dissolved in part of the water (the part of the water is 70% of the total water), beating, and the cornstarch solution is made for subsequent use;

[0032] Acrylic acid is dissolved in a part of water according to the above-mentioned preparation amount to prepare an acrylic acid solution for subsequent use;

[0033] The maleic acid is dissolved in part of the water according to the above-mentioned preparation amount, and the maleic acid solution is made for subsequent use;

[0034] Dissolve ammonium persulfate and urea in part of the water according to the above-mentioned preparation amount to prepare a composit...

Embodiment 2

[0039] The preparation method of the starch-based scale inhibitor of the present embodiment, the steps are specifically:

[0040] 1. Material preparation

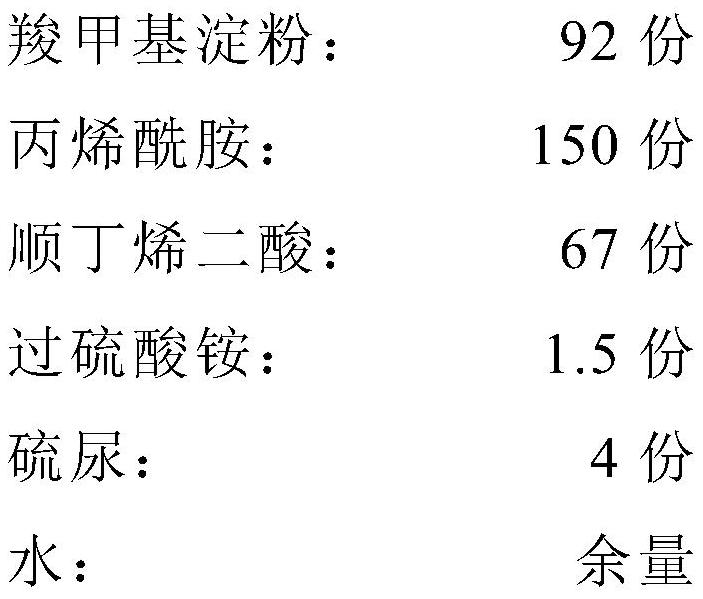

[0041] Calculated by producing 1000 mass parts of antiscalants, the amount of each ingredient (mass parts) is as follows:

[0042]

[0043] The carboxymethyl starch is dissolved in part of the water (the part of the water is 70% of the total water) according to the above-mentioned preparation amount, and beating is made to make a carboxymethyl starch solution for subsequent use;

[0044] Acrylamide is dissolved in part of the water according to the above-mentioned preparation amount to prepare an acrylamide solution for subsequent use;

[0045] The maleic acid is dissolved in part of the water according to the above-mentioned preparation amount, and the maleic acid solution is made for subsequent use;

[0046] Ammonium persulfate and thiourea are dissolved in part of the water according to the above-mentioned preparati...

Embodiment 3

[0051] The preparation method of the starch-based scale inhibitor of the present embodiment, the steps are specifically:

[0052] 1. Material preparation

[0053] Calculated by producing 1000 mass parts of antiscalants, the amount of each ingredient (mass parts) is as follows:

[0054]

[0055]

[0056] According to the above-mentioned preparation amount, the cornstarch is dissolved in part of the water (the part of the water is 70% of the total water), beating, and the cornstarch solution is made for subsequent use;

[0057] Acrylic acid is dissolved in a part of water according to the above-mentioned preparation amount to prepare an acrylic acid solution for subsequent use;

[0058] The maleic acid is dissolved in part of the water according to the above-mentioned preparation amount, and the maleic acid solution is made for subsequent use;

[0059] Dissolve ammonium persulfate and urea in part of the water according to the above-mentioned preparation amount to prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com