Polyhydroxyl tri-hydrazide initiator and preparation method thereof

A polyhydroxy ternary hydrazide and initiator technology, which is applied in the preparation of hydrazides and organic chemistry, can solve the problems of limited chemical design, and achieve the effects of low energy consumption, pure products, and mild and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

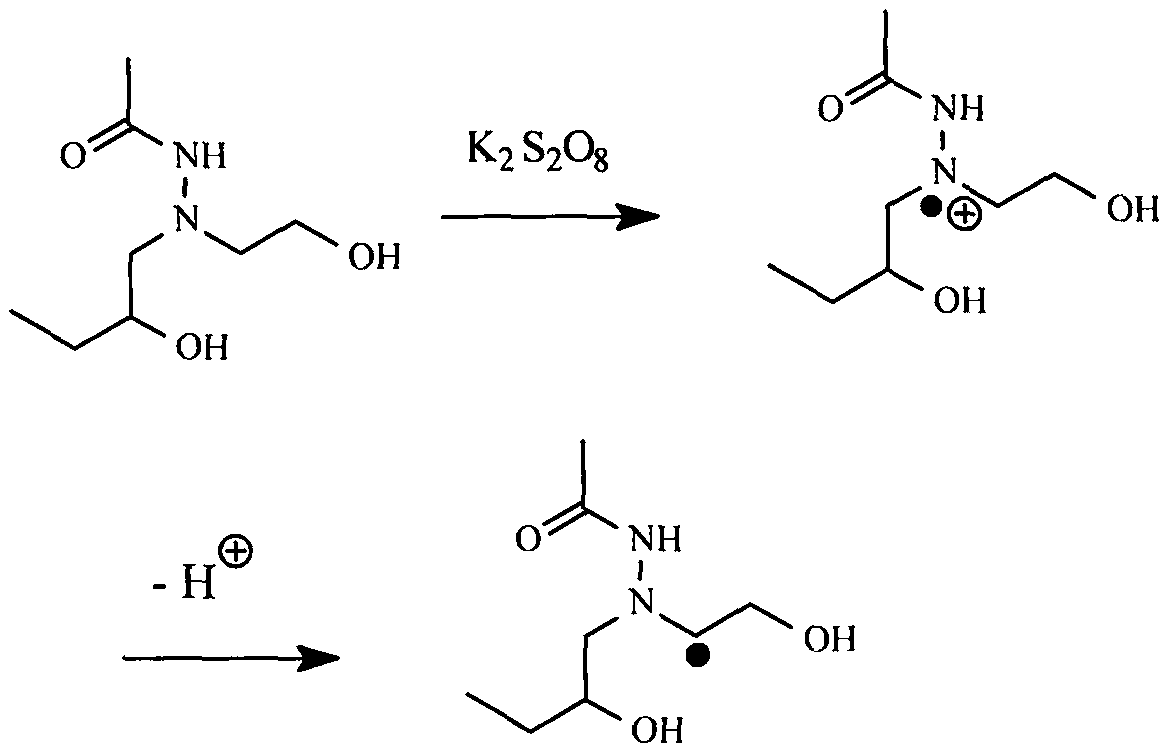

Problems solved by technology

Method used

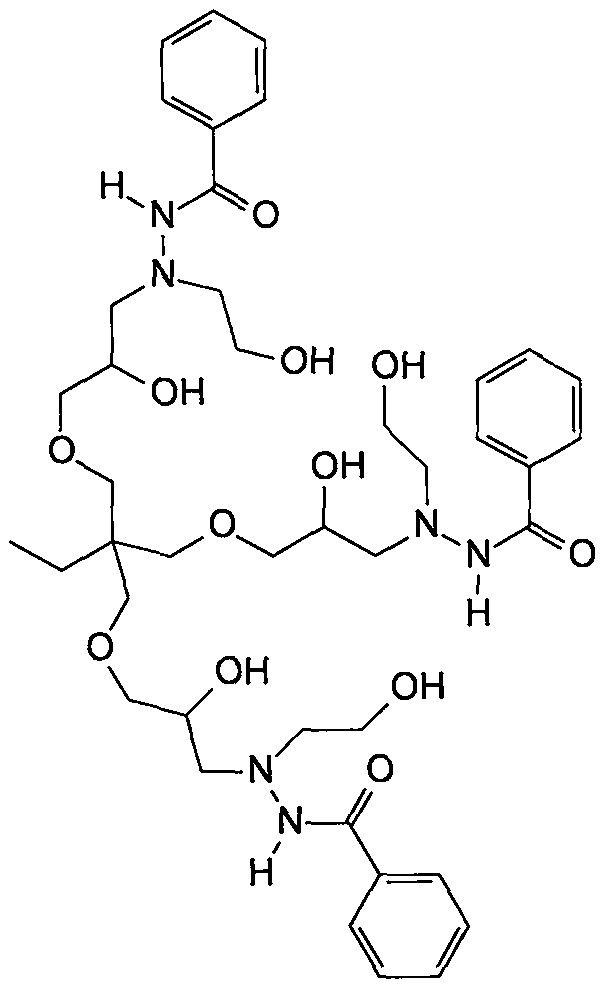

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is described in further detail.

[0018] The preparation of polyhydroxyl ternary hydrazide initiator:

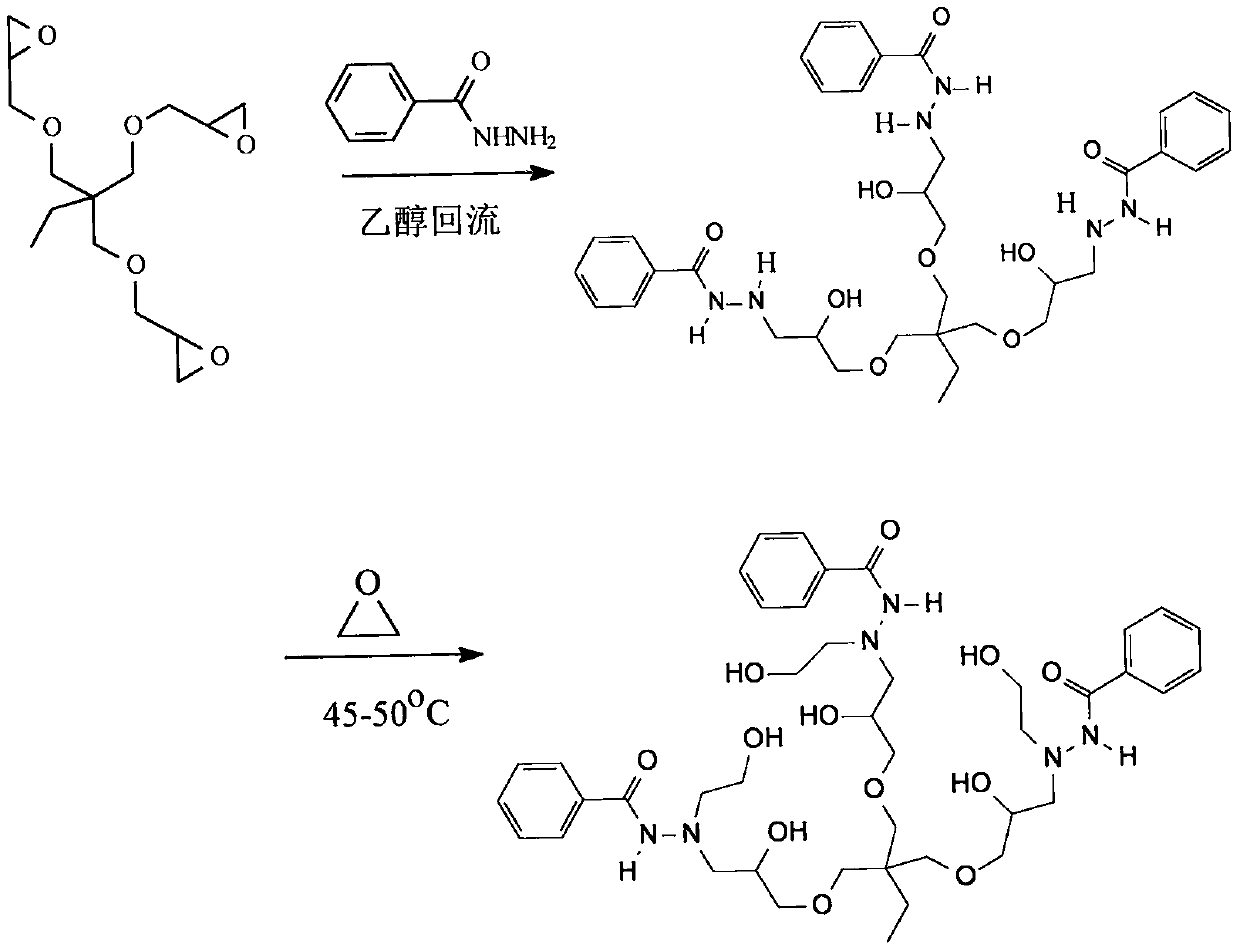

[0019] 1. Mix and dissolve trimethylolpropane triglycidyl ether and benzohydrazide in absolute ethanol at a molar ratio of 1:3, and control the mass ratio of trimethylolpropane triglycidyl ether to ethanol at 1: 3.5 to 1:4 range, keep the reaction solution under reflux for 3 to 4 hours under stirring;

[0020] 2. Transfer the above reaction solution into a high-pressure reactor, and add ethylene oxide, the molar ratio of ethylene oxide to benzohydrazide is controlled at 1.2:1, and the reaction temperature is controlled at 45-50°C after closing the reactor range, the reaction time is 3 to 4 hours, and then the reactor is cooled to room temperature;

[0021] 3. Concentrate the solution in the reaction kettle with a rotary evaporator to remove ethanol, and finally obtain a light yellow viscous substance, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com